Method and test rig for testing a combination of components of a vehicle

A combination and test bench technology, applied in vehicle testing, mechanical component testing, machine/structural component testing, etc., can solve insufficient simulation and testing of high dynamic braking process, insufficient simulation and testing, delay time limits etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

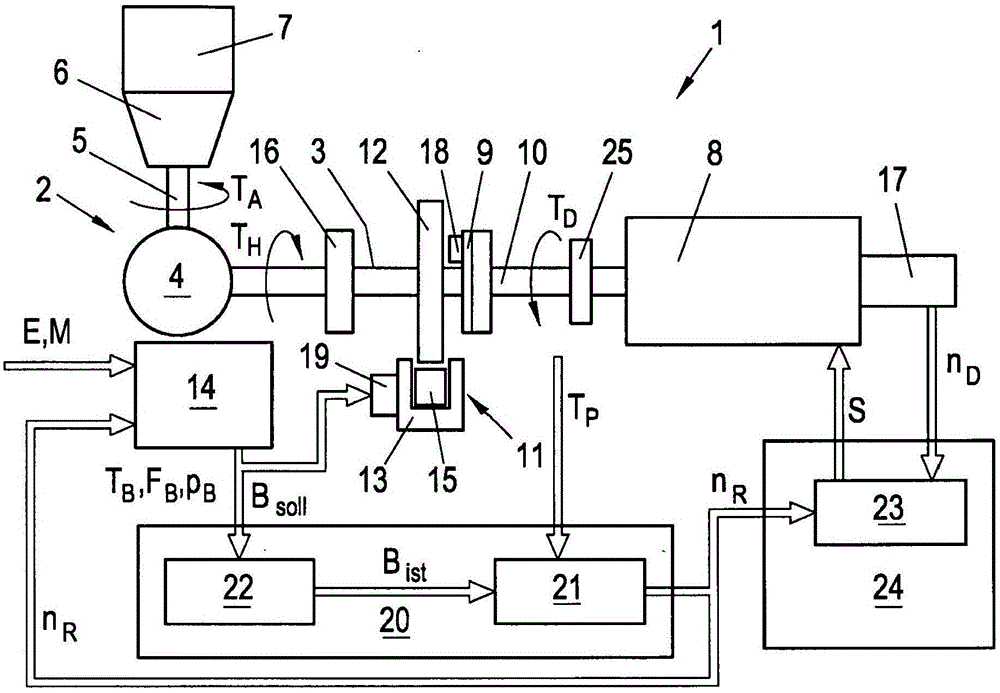

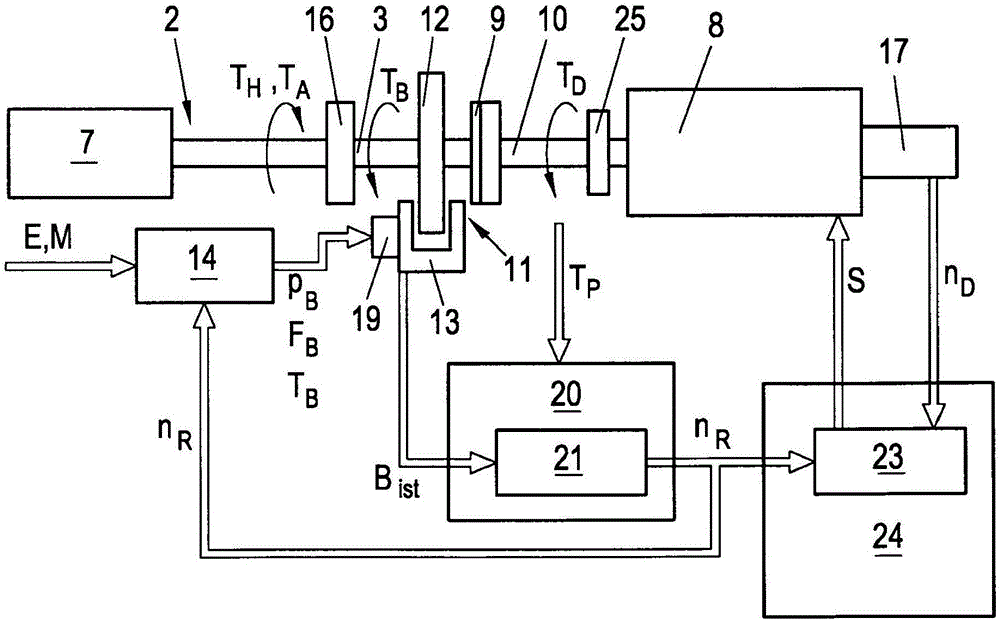

[0024] figure 1 A drive train test stand is shown schematically as test stand 1, which comprises a vehicle drive train 2, which here comprises sideshafts 3, a differential 4, a drive shaft 5 and a transmission 6 as real components, which are operatively Installed on test bench 1. The drive train 2 is driven by a drive 7, such as an internal combustion engine or an electric motor, and generates a drive torque T A , which induces a sideshaft moment T H . Hereinafter it is generally referred to as the drive train torque T P , which collectively refer to the torque acting in the drive train 2 . The drive train 2 is connected to a loader 8, preferably an electric loader (dynamometer). For this purpose, the loader 8 is connected in a rotationally fixed manner to the wheel 9 , possibly via a suitable load shaft 10 , such as a cardan shaft, only the wheel hub being shown here for the sake of simplicity. Loader 8 produces load torque T D , which is applied to the drive train 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com