Automotive fuel supply pressure and fuel atomization automatic adjustment device

An automatic adjustment device and fuel supply technology, applied in liquid fuel feeder, fuel re-atomization/homogenization, combustion air/combustion-air treatment, etc., can solve the problem of unsatisfactory fuel atomization supply effect and insufficient Solve problems such as particulate fuel and liquid fuel with fast flow rate to achieve the effects of increasing power, saving fuel, and reducing engine vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The fuel supply pressure and fuel atomization automatic adjustment device of the present invention will be described in detail below with reference to the accompanying drawings.

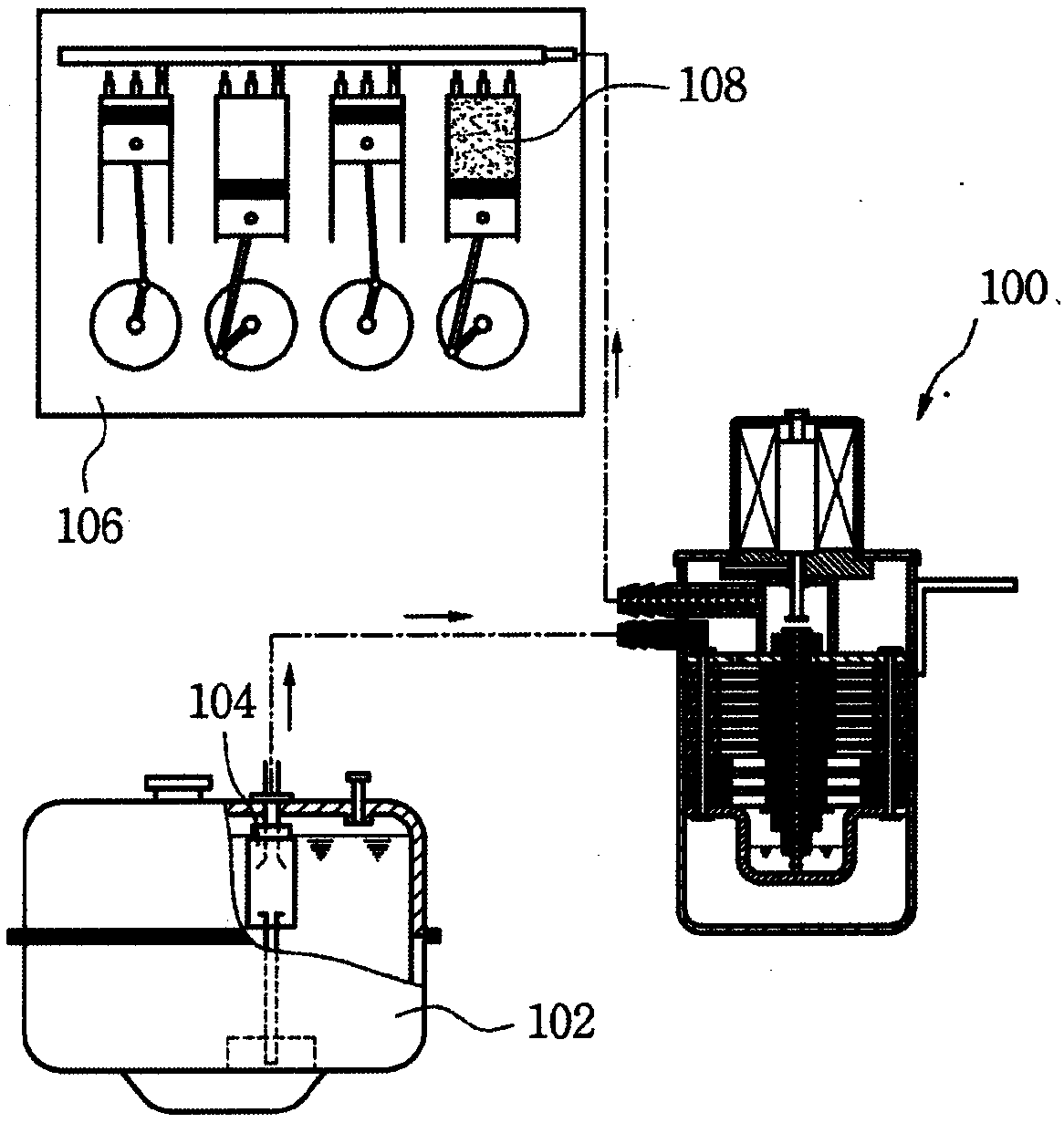

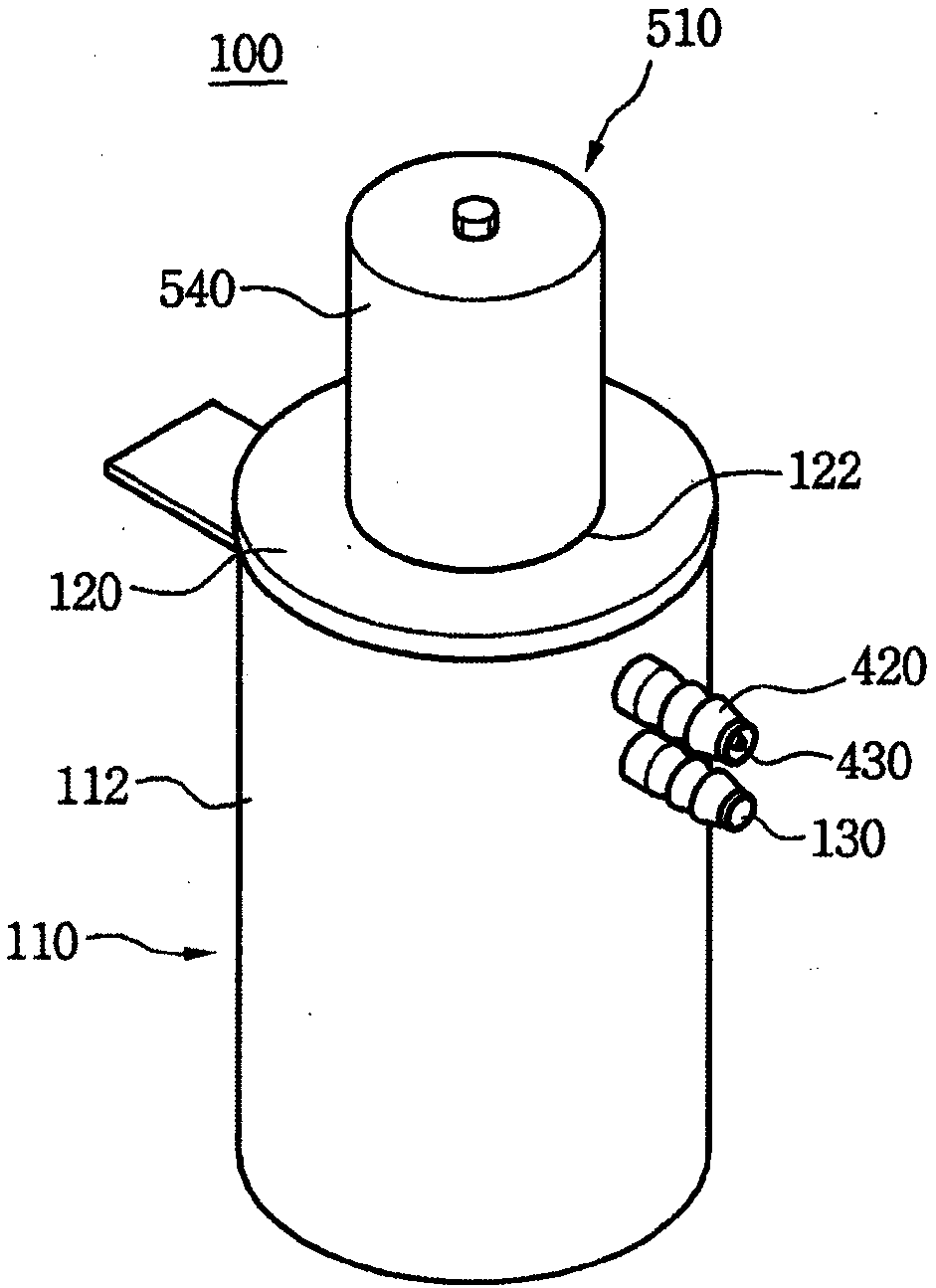

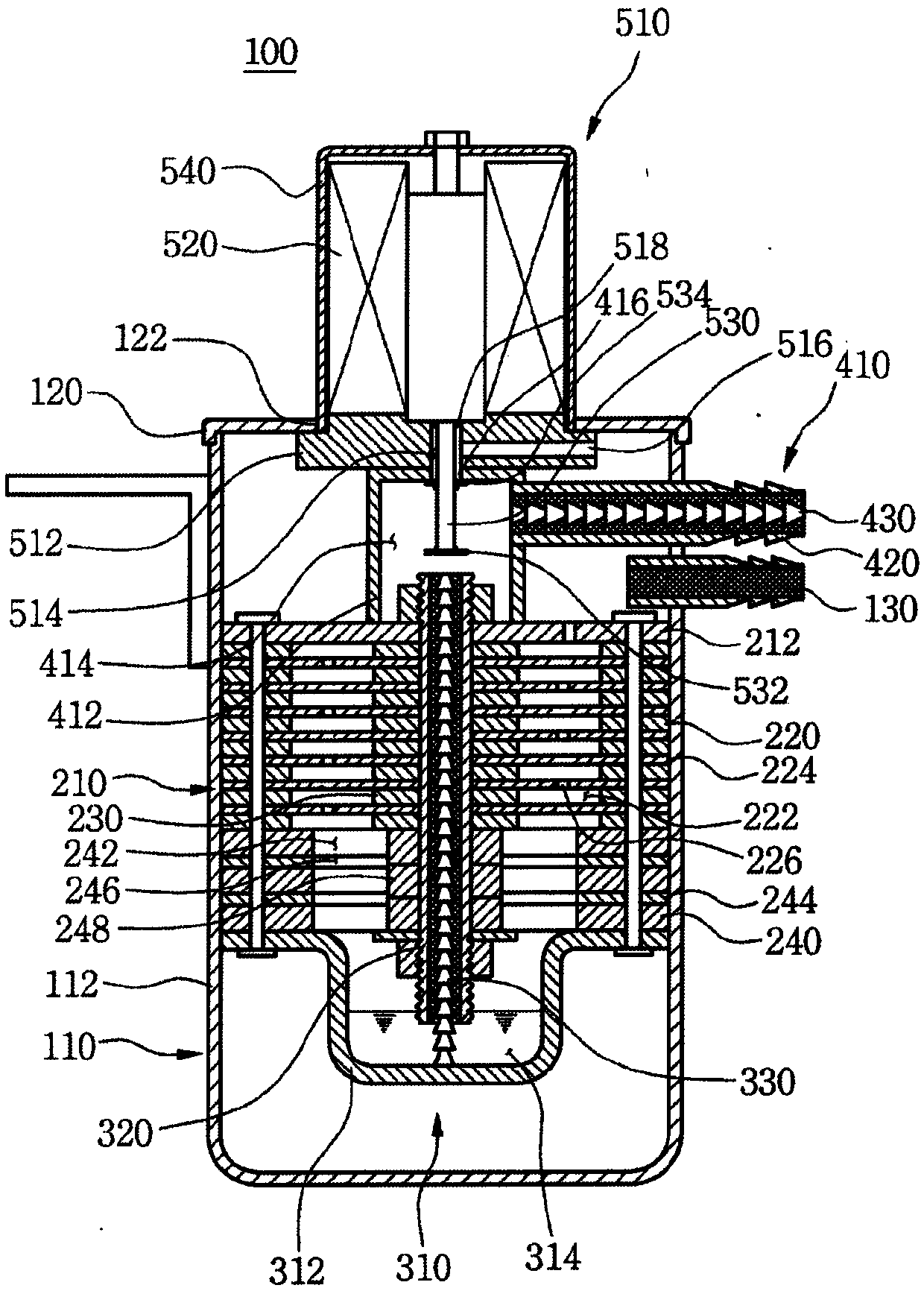

[0058] figure 1 It is a schematic diagram showing the state in which the fuel storage tank of the present invention is installed between the fuel chamber of the engine, figure 2 It is a perspective view showing an automatic adjustment device for fuel supply pressure and fuel atomization of an automobile according to the present invention, image 3 It is a cross-sectional view illustrating an automatic adjustment device for fuel supply pressure and fuel atomization of an automobile according to the present invention, Figure 4a and Figure 4b is a diagram showing a fuel control unit of the present invention, Figure 5a and Figure 5b It is a figure showing the fuel supply part of this invention, Image 6 It is a figure which shows the fuel discharge part and the fuel supply switching part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com