Fingerprint module applied hot and cold pressure integrated processing apparatus

A fingerprint module and comprehensive processing technology, which is used in the assembly of printed circuits with electrical components, PCB positioning during processing, etc., which can solve problems such as low production efficiency, cooling of products that cannot be hot-pressed, and much time for intermediate circulation. , to achieve the effect of preventing product deformation, improving safety and accurate pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

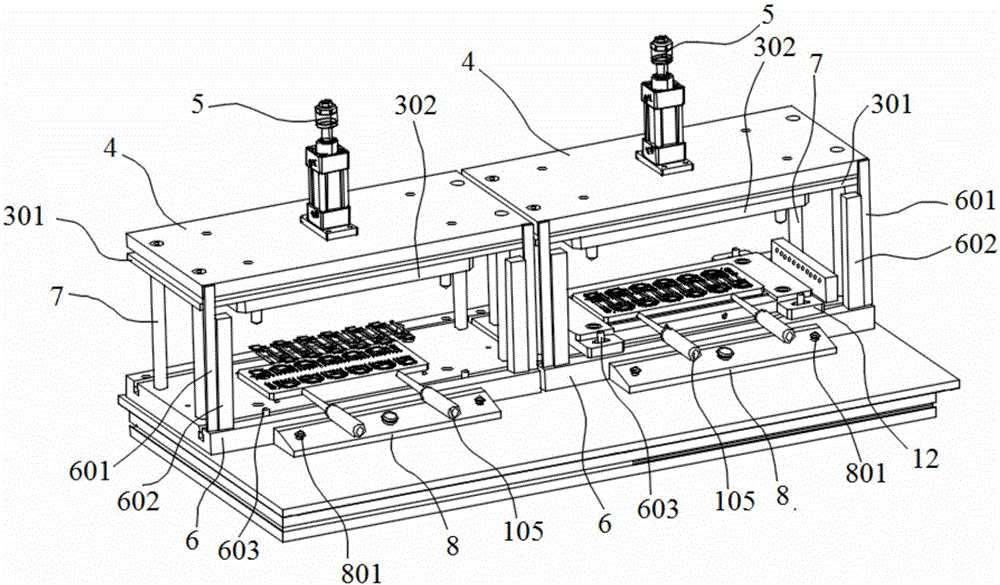

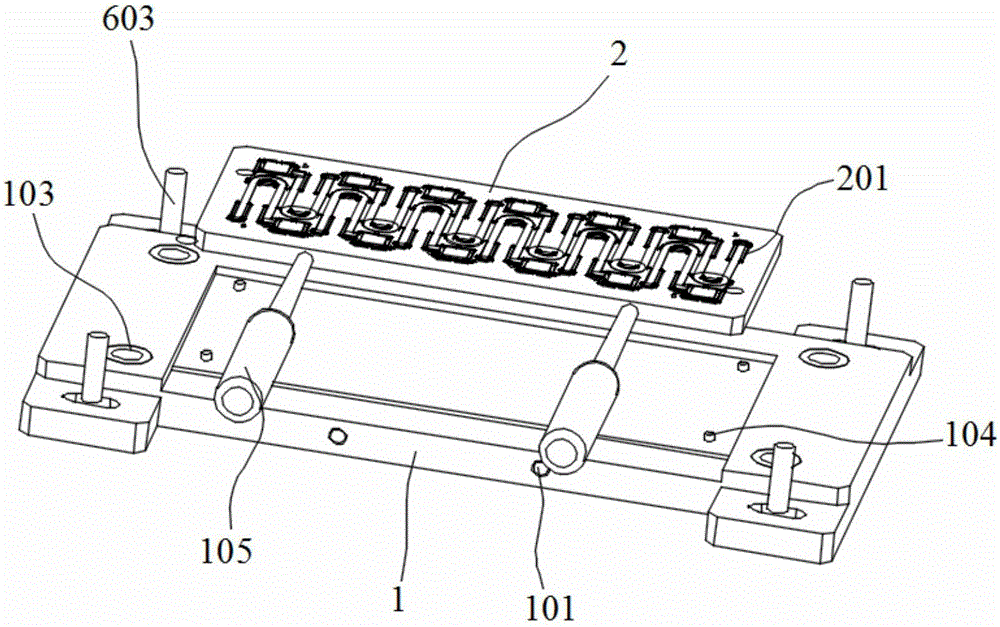

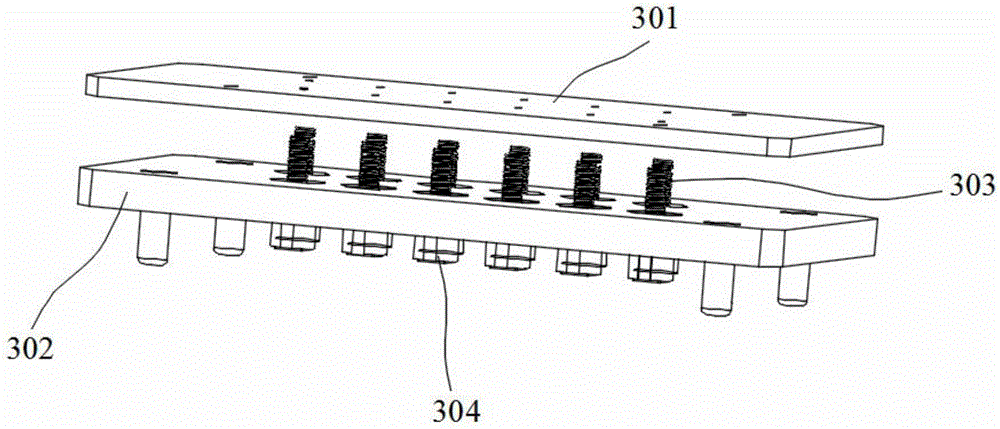

[0028] Embodiment 1: A comprehensive hot and cold pressing processing device for fingerprint modules, including a substrate 1, a loading plate 2, a vertical buffer pressure mechanism 3, a fixed plate 4 and a vertical cylinder 5, and the loading plate 2 is installed on the base plate 1 On the upper surface, the substrate 1 is mounted on a base plate 6, and the two ends of the base plate 6 and the two ends of the fixed plate 4 are fixedly connected by the left side plate 401 and the right side plate 402 respectively, and at least two guide posts 7 are fixed on the fixed plate 4 and the bottom plate 6, the at least two guide posts 7 are respectively on both sides of the base plate 1, the vertical buffer pressure mechanism 3 is located between the fixed plate 4 and the loading plate 2, and the vertical cylinder 5 is installed on the fixed plate 4 On the upper surface, the piston rod 501 of the vertical cylinder 5 runs through the fixed plate 4 and its end is connected to the vertic...

Embodiment 2

[0033] Embodiment 2: A comprehensive processing device for hot and cold pressing for fingerprint modules, including a substrate 1, a loading plate 2, a vertical buffer pressure mechanism 3, a fixed plate 4 and a vertical cylinder 5, and the loading plate 2 is installed on the base plate 1 On the upper surface, the substrate 1 is mounted on a base plate 6, and the two ends of the base plate 6 and the two ends of the fixed plate 4 are fixedly connected by the left side plate 401 and the right side plate 402 respectively, and at least two guide posts 7 are fixed on the fixed plate 4 and the bottom plate 6, the at least two guide posts 7 are respectively on both sides of the base plate 1, the vertical buffer pressure mechanism 3 is located between the fixed plate 4 and the loading plate 2, and the vertical cylinder 5 is installed on the fixed plate 4 On the upper surface, the piston rod 501 of the vertical cylinder 5 runs through the fixed plate 4 and its end is connected to the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com