A Design Method of Bead Parameters Based on Bead Pressure

A parametric design, bead technology, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve problems such as high cost and low efficiency, and achieve the effect of shortening the time required for design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

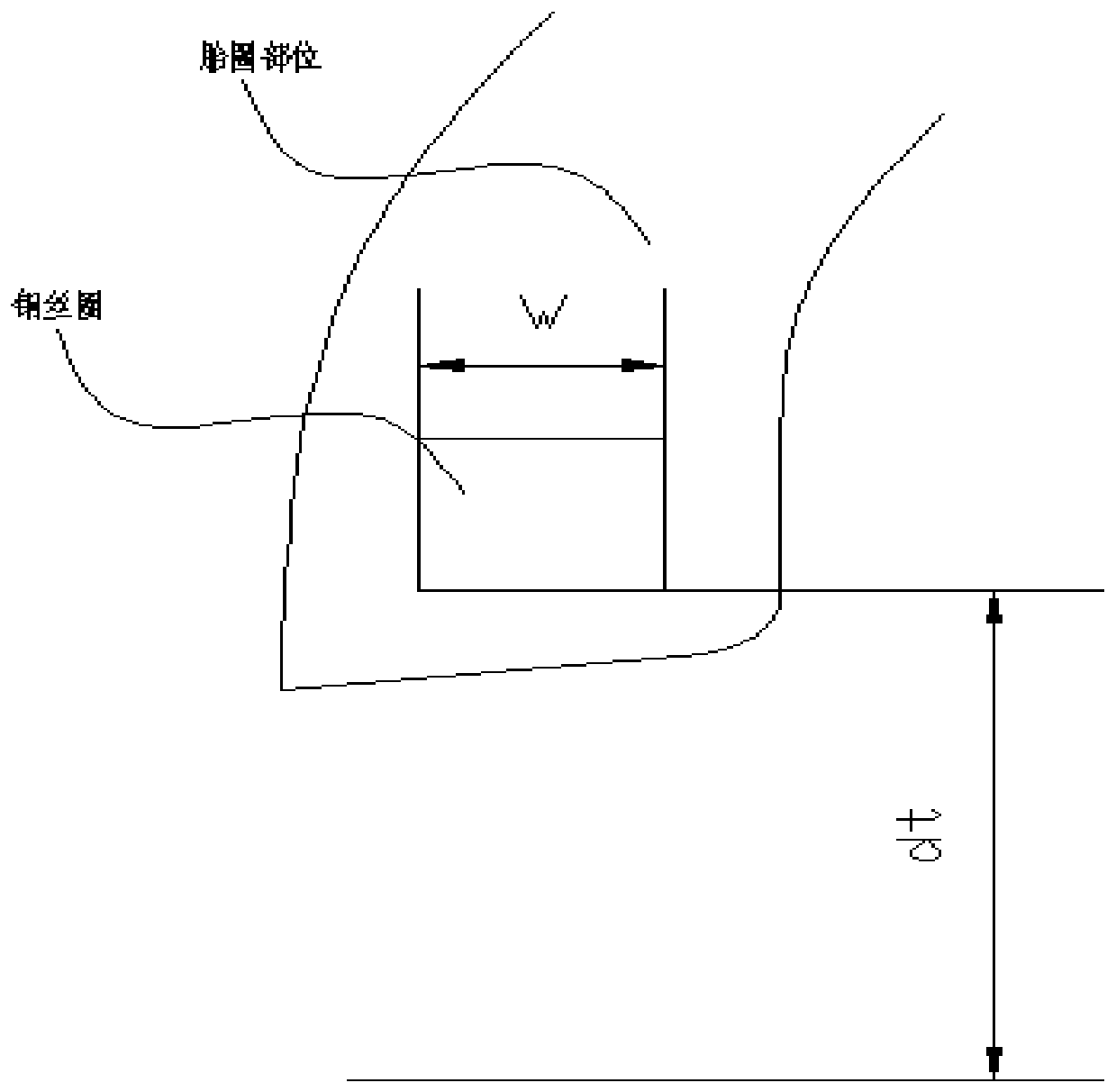

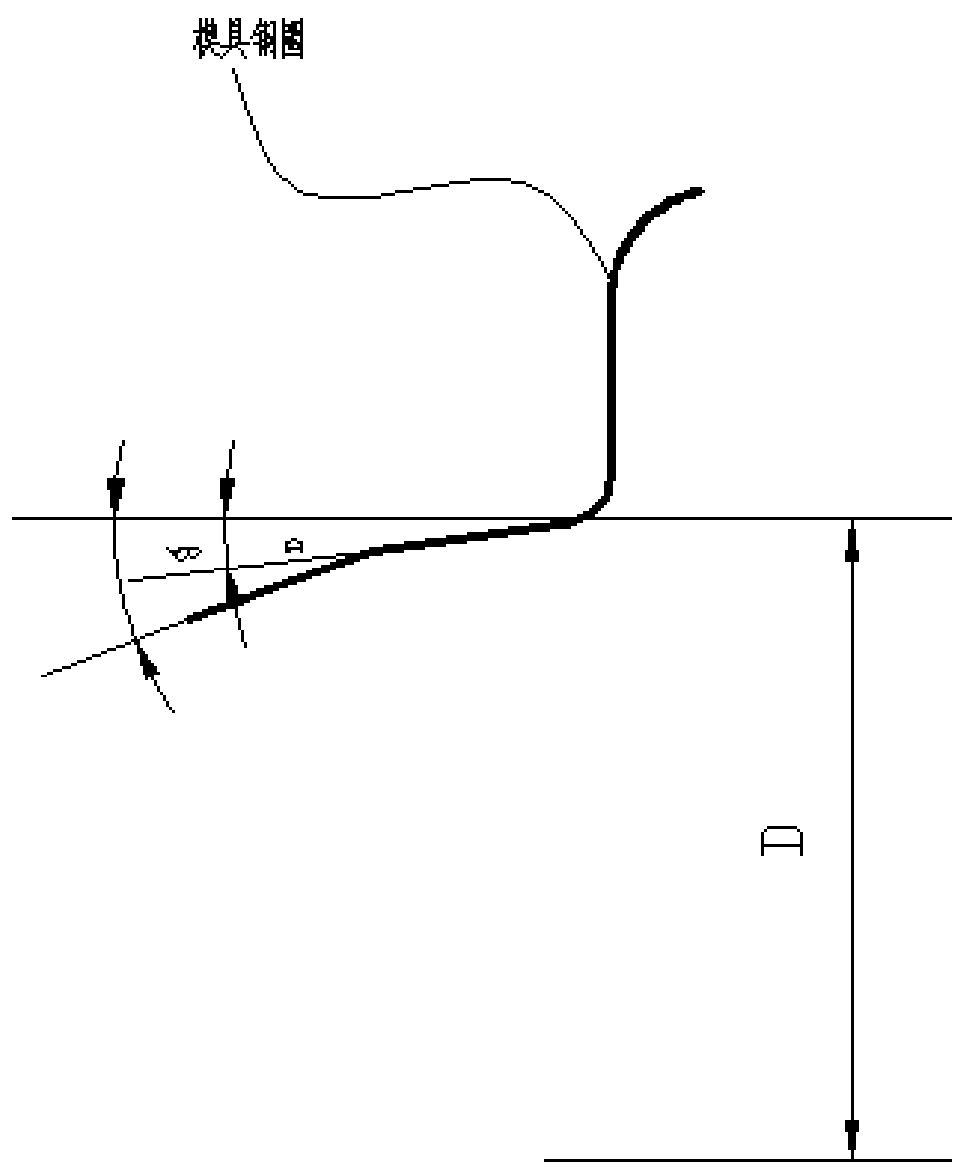

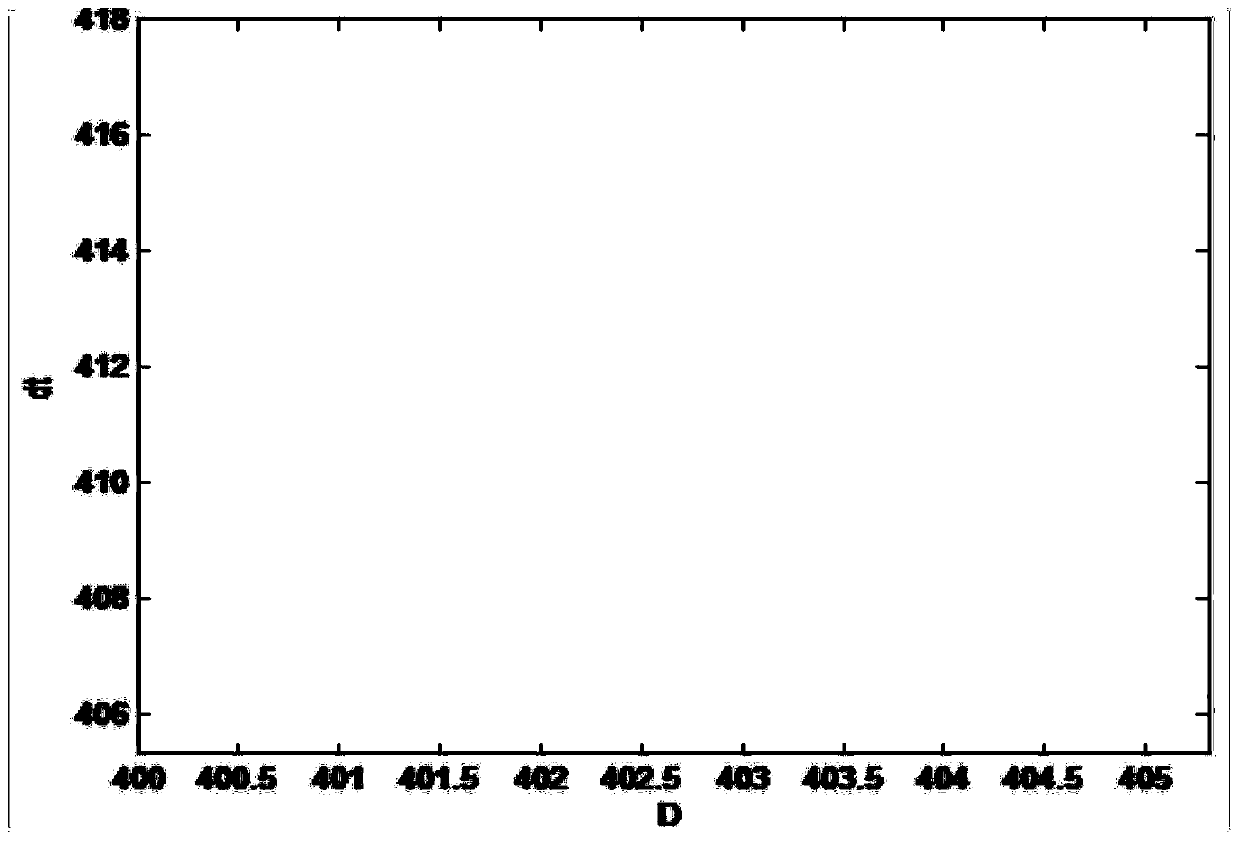

[0038] Example 1: According to the different design requirements, assuming that the 205 / 55R16 specification adopts a design of 1 layer of cord fabric without steel wire wrapping, the engagement diameter D of the mold steel ring and the inner diameter d of the traveler can be obtained t The thickness G of the formed bead bottom material is as Figure 4 As shown, assuming G=2.76mm, then get d t -D=2×G=5.52mm, then according to image 3 The engagement diameter D of the die ring and the inside diameter d of the traveler shown t relationship, it is easy to get the traveler diameter d t is 409.52mm, and the engagement diameter D of the mold steel ring is 404mm.

Embodiment 2

[0039] Embodiment two: Assume that there is an existing mold steel ring, and it is known that its engagement diameter D is 404mm, then according to image 3 Engagement diameter D of the die ring shown and inner diameter d of the traveler t The relationship between the inner diameter of the traveler d t It is 409.52mm. And the design of the material thickness G at the bottom of the bead should also satisfy (d t -D) / 2=2.76mm requirement.

Embodiment 3

[0040] Embodiment 3: Assume that there is an existing traveler, and the inner diameter d of the traveler t is 409.52mm, then according to image 3 Engagement diameter D of the die ring shown and inner diameter d of the traveler t According to the relationship, the diameter D of the mold steel ring is 404mm. And the design of the material thickness G at the bottom of the bead should also satisfy (d t -D) / 2=2.76mm requirement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com