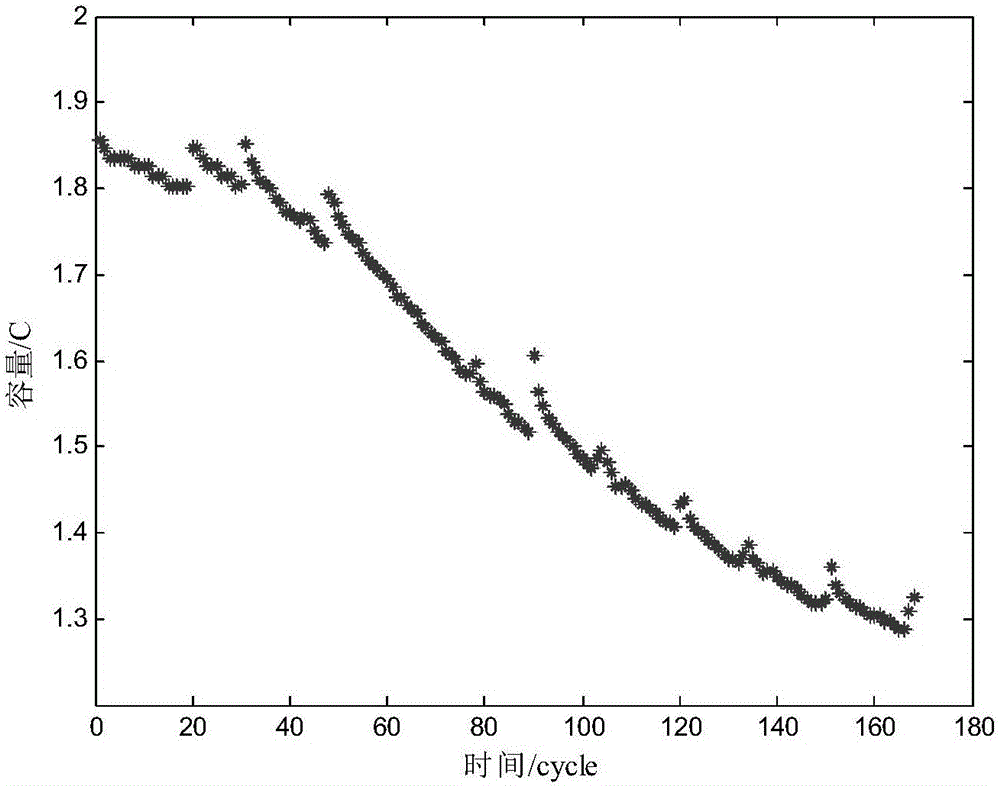

Fused HI equivalence lithium ion battery degradation prediction method based on principal component analysis

A lithium-ion battery, principal component analysis technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problem that the accuracy is greatly affected by the current sampling accuracy and the initial value of the integral, and the physical model of lithium-ion battery capacity degradation is difficult to build , difficult capacity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following examples.

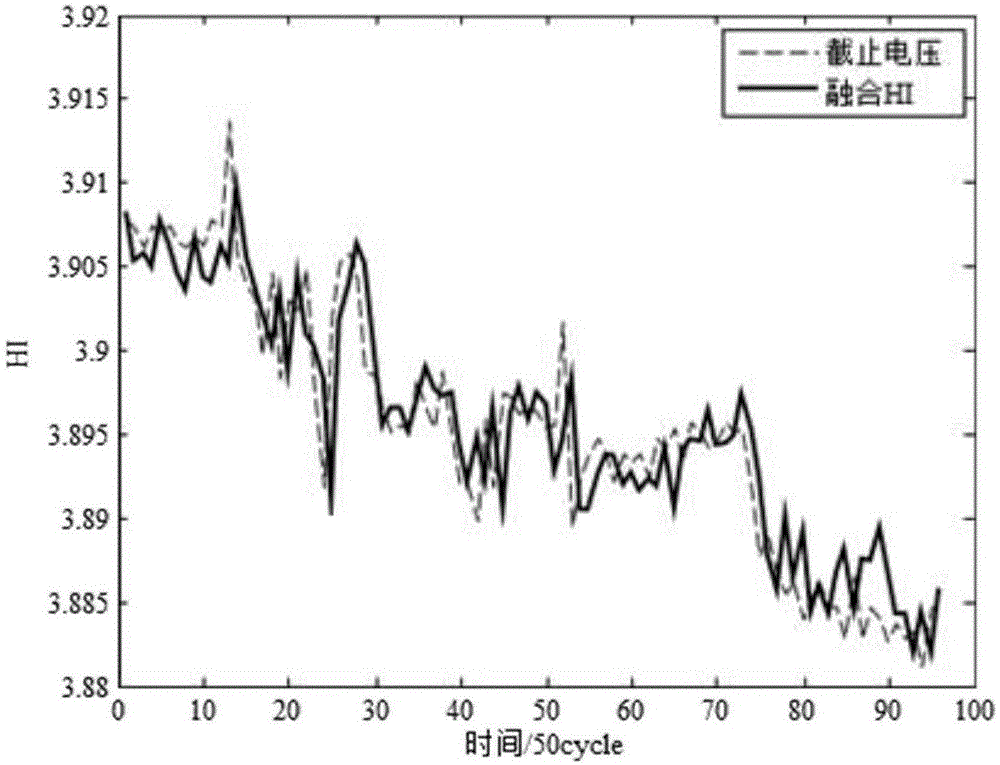

[0039] A method for predicting the equivalent degradation of fusion HI based on principal component analysis involved in this embodiment, the steps are as follows:

[0040] Step 1. Multiple sets of data of n HI (Health Index, health factor) obtained by extracting data constitute a (m×n) dimensional original data matrix

[0041] Step 2, perform standardization processing on matrix A: standardize each row element in matrix A, so as to obtain X=(x ij ) m×n ;

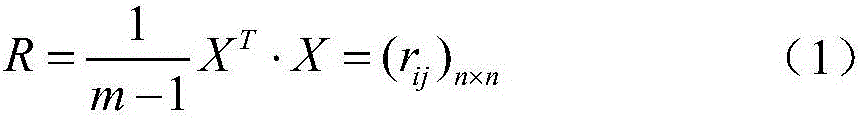

[0042] Step 3, for the normalized sample matrix X obtained by step 2, further calculate the correlation coefficient matrix of the standardized matrix as shown in formula (1);

[0043]

[0044] Step 4: Using the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com