Water-saving fog-dissipation closed cooling tower with float valve structure

A closed-type cooling tower and demisting closed-type technology, applied in the direction of water shower coolers, direct contact heat exchangers, fixed conduit components, etc., can solve the problems of spray water evaporation loss and reduce evaporation loss and wind blowing loss, easy installation and maintenance, and the effect of reducing outlet air temperature and humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

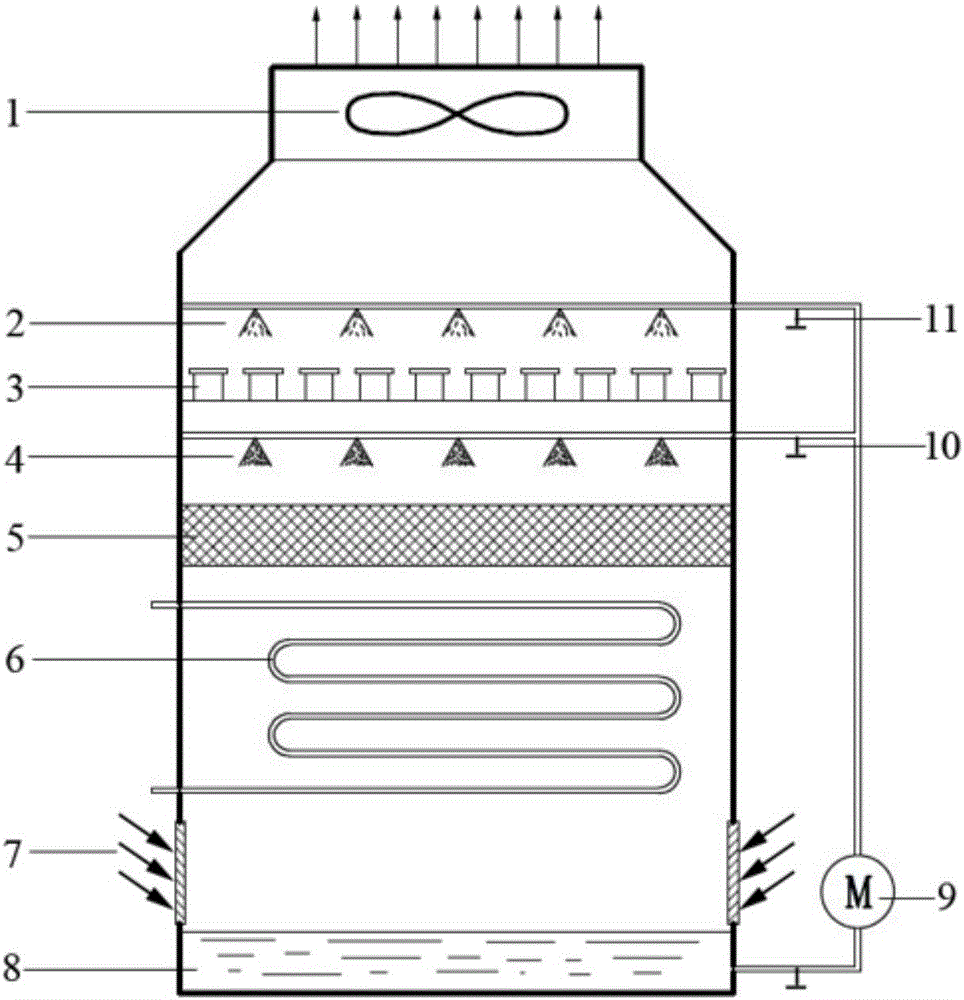

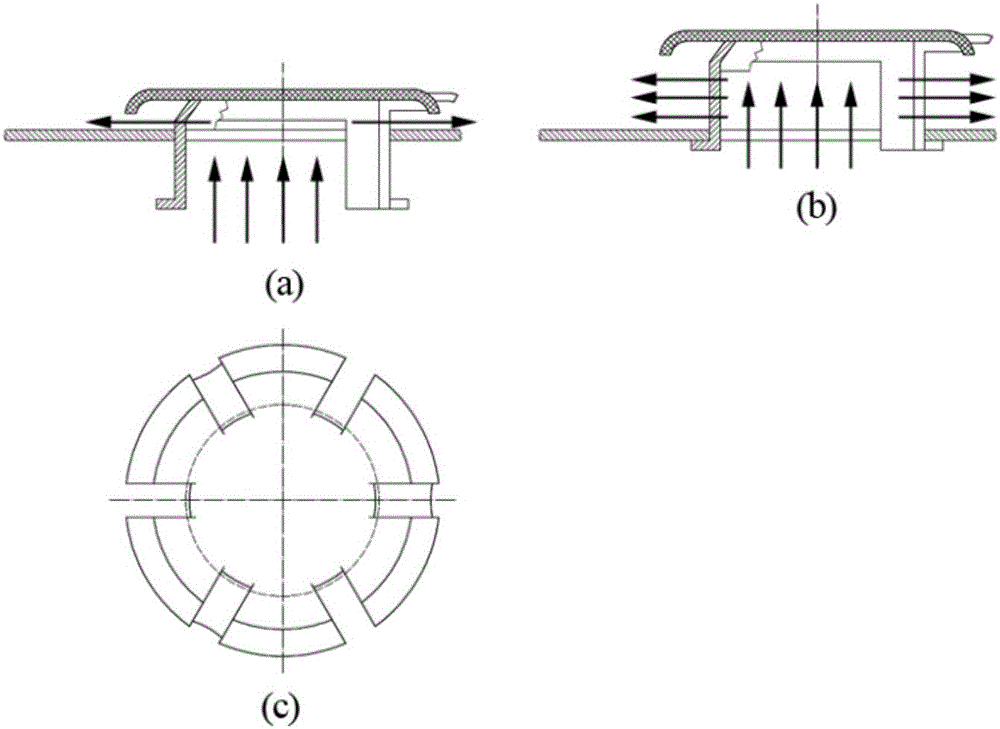

[0023] Embodiment 1: A water-saving and fog-eliminating closed cooling tower with a floating valve structure. The tower body is respectively equipped with a fan system 1, a spray system 2, a float valve element 3, a spray system 4, and a packing part from top to bottom. 5. Cooling coil 6, air inlet 7, reservoir 8; floating valve components in the tower such as figure 2 Material shown is copper. The float valve element 3 is located below the spray system 2 on the top of the tower, and above the lower spray system 4 and the packing part; the operation process: the spray water enters the upper and lower spray systems 2 and the upper and lower spray systems from the tank 8 at the bottom of the tower through the spray pump 9 4, and set the floating valve element 3 in the middle of the upper and lower spraying systems. After the spray water is evenly distributed by the filler 5, it is sprayed on the surface of the coil 6; the fan 1 on the top of the tower rotates to generate negat...

Embodiment 2

[0024] Embodiment 2: A water-saving and fog-eliminating closed cooling tower with a floating valve structure. The tower body is respectively equipped with a fan system 1, a spray system 2, a float valve element 3, a spray system 4, and a packing part from top to bottom. 5. Cooling coil 6, air inlet 7, reservoir 8; floating valve components in the tower such as figure 2 The material shown is made of PVC / PP, and the float valve element 3 is located below the spray system 2 on the top of the tower, and above the lower spray system 4 and the packing part; the operation process: the spray water passes through the spray pump 9 and is stored at the bottom of the tower The pool 8 enters the upper and lower spray systems 2 and 4, and a float valve element 3 is arranged in the middle of the upper and lower spray systems. After the spray water is evenly distributed by the filler 5, it is sprayed on the surface of the coil 6; the fan 1 on the top of the tower rotates to generate negative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com