Metal arc smelting furnace with cooling device

A metal arc and cooling device technology, which is applied in the metal smelting industry, can solve the problems of scrapping, deformation, and unsatisfactory application effects of the smelting furnace, and achieve the effects of stable pouring of metal liquid, good cooling effect, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

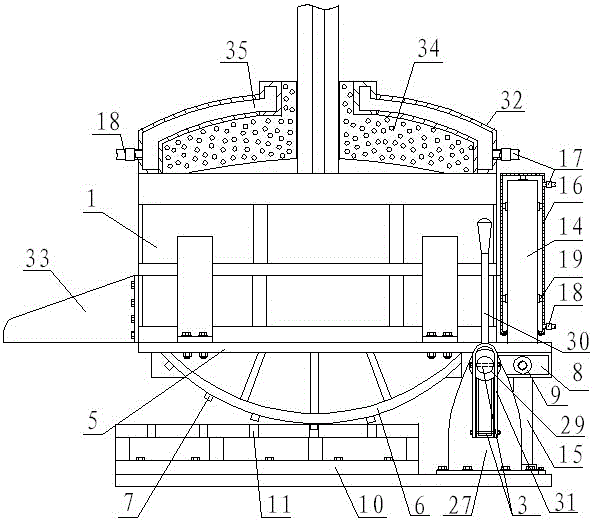

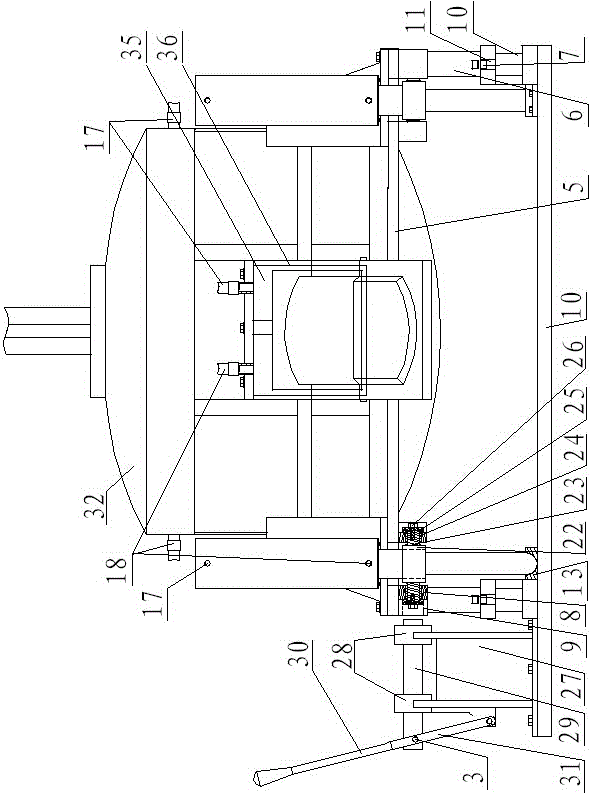

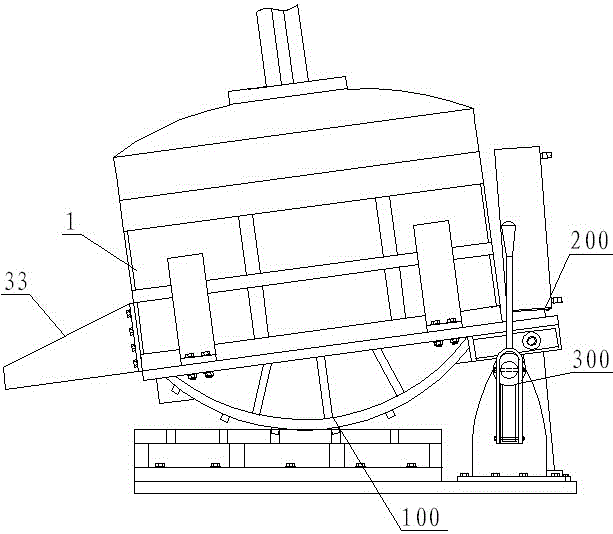

[0023] see Figure 1 ~ Figure 3 , present embodiment comprises base 10, furnace body 1, furnace cover 32, furnace door 36, furnace outlet 33, furnace body 1 is installed on the base 10, furnace cover 32 covers the top of furnace body 1, furnace door 36 and furnace outlet 33 are installed on both sides of the furnace body 1; the furnace cover 32 and the furnace door 36 are provided with cooling chambers 35, and the cooling chambers 35 are provided with water inlet pipes 17 and water outlet pipes 18; the bottom of the furnace body 1 A rolling device 100 is provided, and a power tilting device 200 is provided on one side of the furnace body 1 .

[0024] Water is injected from the water inlet pipe 17, the water enters the cooling chamber 35 and circulates, and overflows from the water outlet pipe 18 to form a water cycle. In the application of the smelting furnace, the high temperature is as high as above 1000 degrees, and the furnace cover 32 and the furnace door 36 are cooled u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com