Wind-heat type wood drying box

An air-heated, drying oven technology, used in non-progressive dryers, veneer drying, drying chambers/containers, etc., can solve problems such as cracking and uneven drying, achieve uniform heat distribution, and avoid uneven drying of wood Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

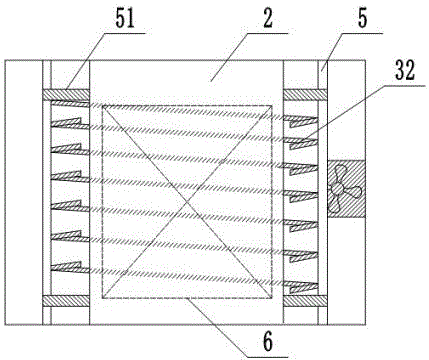

[0016] The reference signs in the accompanying drawings of the description include: box body 1, support plate 2, drum 3, wind plate 31, spiral blade 32, hot air blower 4, protective cover 41, mounting frame 5, bearing 51, wood 6.

[0017] The embodiment is basically as attached figure 1 and figure 2 Shown:

[0018] An air-heated drying box for wood, mainly composed of a box body 1, a hot air blower 4, a support plate 2 and a roller 3, the inner wall of the box body 1 is connected with a mounting frame 5, and the mounting frame 5 is fixedly connected with two ring beams , the two ends of the drum 3 are respectively connected to the ring beam through bearings 51 . The drum 3 is installed by means of the installation frame 5 and the ring beam, the outer peripheral space of the drum 3 is released, and the setting of the bearing 51 reduces the wear of the end of the drum 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com