LED total-reflection lens and LED line source

A technology of total reflection and total reflection surface, applied in refractors, lighting and heating equipment, lighting devices, etc., can solve the problem of easy control without light, and achieve the effect of reasonable main structure and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

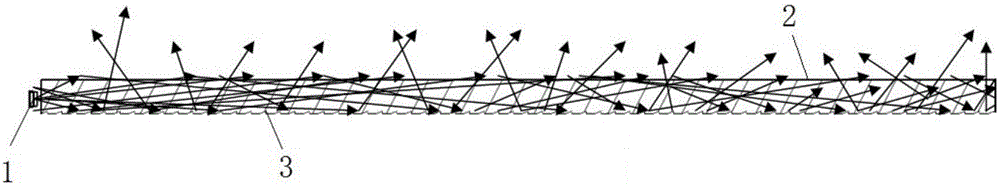

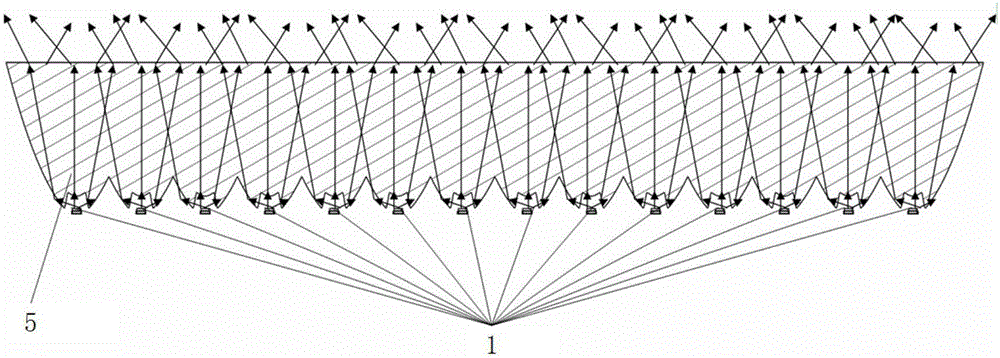

[0047] The invention discloses an LED total reflection lens (lens for short), which is an integral polyhedron, such as Figure 4-14 As shown, the outline of its main body is composed of a cuboid I and two upper and lower 180-degree semi-conical frustums II and III, which are equal in size and completely attached to the lower bottom surface in the middle of the front of the cuboid. The superimposed body of the two 180-degree semi-conical frustums is similar to half a spindle. The so-called 180-degree semi-conical truncated cone refers to any part obtained by cutting with any plane passing through the axis of the truncated cone, and the arbitrary plane can be called a longitudinal plane. The longitudinal plane of the 180-degree semi-conical truncated cone fits with the front of the cuboid and neither left nor right exceeds the front of the cuboid. The upper and lower surfaces of the upper and lower 180-degree semi-conical frustums are respectively flush with the top and bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com