Coal seam coring sealing device and sealing coring method thereof

A sealing device and coal seam technology, which is applied in the direction of extracting the undisturbed core device, earthwork drilling and mining, etc., can solve the problem of not considering the loss of gas, and achieve the effects of reducing the extrusion force, prolonging the service life, and reliable torque transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

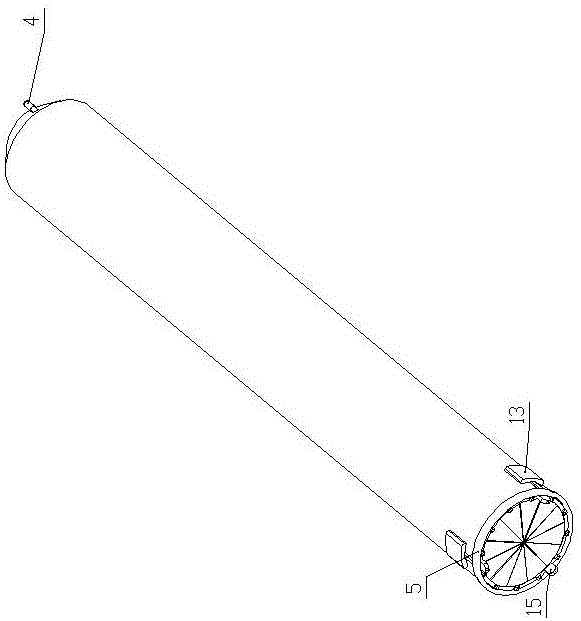

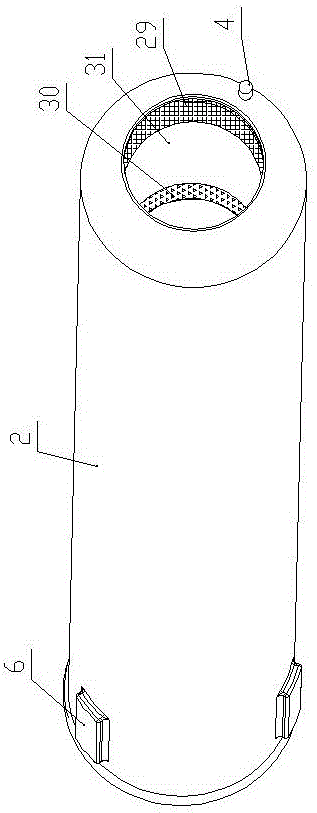

[0037] Such as Figure 1-8 As shown, the sealing device for coal seam coring of the present invention includes inner drill rod 1, outer drill rod 2 and power drill rod 3 all of which are hollow structures, and the inner drill rod 1 is slidably inserted in the outer drill rod 2, and the inner drill rod 1 The joint with the outer drill pipe 2 is connected by a sealing sleeve 31, the sealing sleeve 31 is integrally made with the outer drill pipe, and the bottom end of the power drill pipe 3 is connected with the top end of the inner drill pipe 1;

[0038] The outer wall of the sealing sleeve 31 is fixedly connected with the inner wall of the outer drill pipe 2, and the pipe wall of the sealing sleeve 31 is provided with an air hole communicating with the inside of the outer drill pipe 2 along the axial direction, and the air hole is equipped with an air hole cap 4; the bottom of the outer drill pipe 2 There are airbags 5, three groups of inflation mechanisms 6 and twelve groups o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com