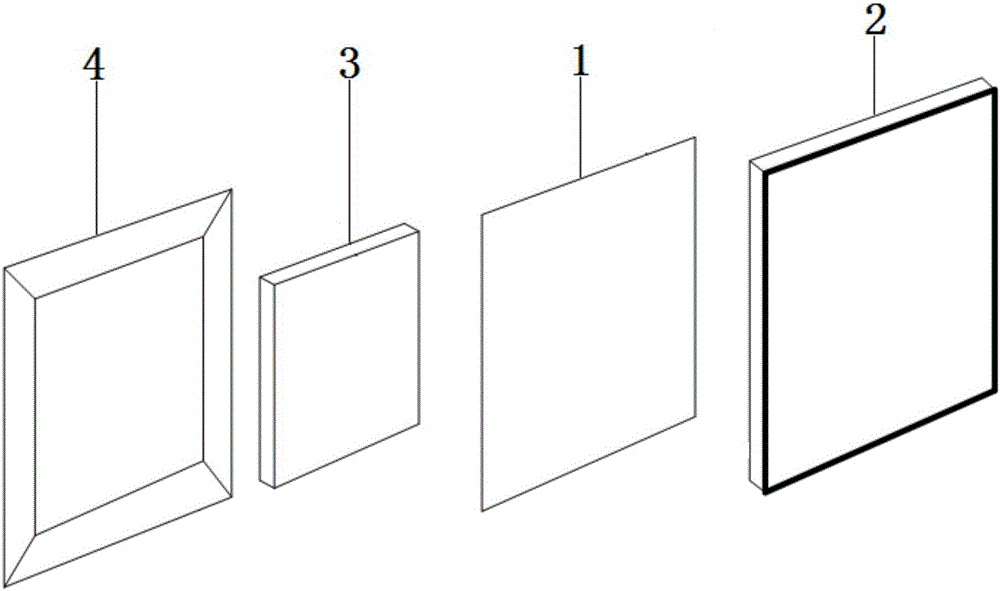

Fluorescent powder, preparation method thereof, fluorescent powder film sheet, and fluorescent powder module structure

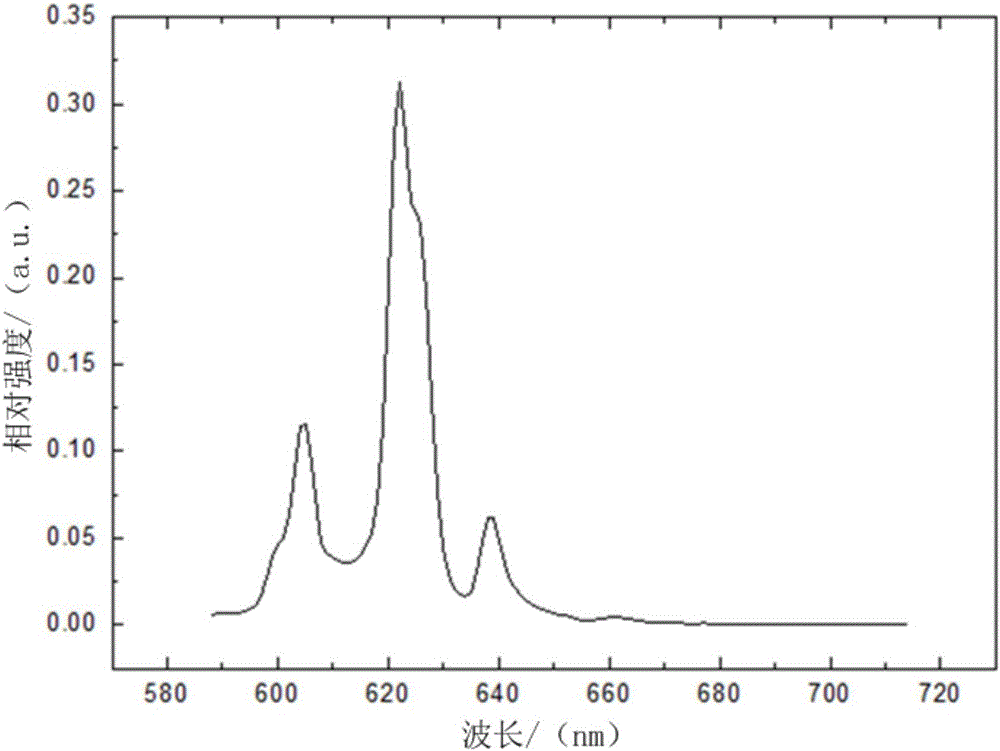

A technology of phosphor film and module structure, applied in the field of phosphor module structure, phosphor and its preparation, and phosphor film, can solve the problem of low color gamut, half-wave width of excitation peak, low luminous efficiency, etc. problem, to achieve the effect of high luminous efficiency, narrow half-wave width, and high color gamut value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In the second aspect, the embodiment of the present invention also provides a method for preparing the above-mentioned fluorescent powder, the preparation method comprising the following steps:

[0046] Step 101, put tetraethyl orthosilicate, absolute ethanol, ammonia water, and deionized water in a molar ratio of 2-6:2-6:0.5-2:0.5-2 into a beaker, mix and stir, then heat in a water bath, and dry , to get SiO 2 Microspheres.

[0047] Step 102, add the oxide of europium into dilute nitric acid solution to dissolve, and Sr(NO 3 ) 2 , M β (CO 3 ) γ 1. Deionized water is placed in the reactor and mixed, then the mixed solution of europium oxide and dilute nitric acid solution is added to the reactor, and the mixture is evenly stirred; wherein, Sr(NO 3 ) 2 , M β (CO 3 ) γ , deionized water, and the molar ratio of the oxides of europium are 15-20:1-3:60:1-5, and M is Li, Na, K, Sr, Ba, or Zn.

[0048] Step 103, continue to add chelating agent and coupling agent in ...

Embodiment 1

[0070] This example provides a composition of SiO 2 -LiSrSiO 4 :0.06Eu 3+ Phosphor powder with a core-shell structure, which is prepared by the following method: put tetraethyl orthosilicate, absolute ethanol, ammonia water, and deionized water in a beaker with a molar ratio of 4:4:1:1 Stir at 60°C for 30min, then heat in a water bath at 28°C for 30min, and then dry in a vacuum oven at 100°C with a pressure of 98Pa for 8h to obtain SiO 2 Microspheres, ready for use; 0.18molSr(NO 3 ) 2 , 0.02molLi 2 CO 3 , 0.6mol of deionized water is placed in the reactor, and 0.03mol of Eu 2 o 3 Dissolve in 30ml of dilute nitric acid solution with a mass concentration of 45%. 2 o 3 After complete dissolution, the Eu 2 o 3 Add the mixed solution of dilute nitric acid solution into the reactor and stir evenly, further add 0.072mol citric acid and 0.036mol polyethylene glycol into the reactor, heat to 60°C, stir the mixed solution until it is transparent; then put the above SiO 2 Pla...

Embodiment 2

[0072] This example provides a composition of SiO 2 -BaSrSiO 4 :0.04Eu 3+ Phosphor powder with a core-shell structure, which is prepared by the following method: put tetraethyl orthosilicate, absolute ethanol, ammonia water, and deionized water in a beaker with a molar ratio of 4:4:1:1 Stir at 58°C for 28min, then heat in a water bath at 28°C for 31min, and further dry at 110°C in a vacuum oven at 98Pa for 9h to obtain SiO 2 Microspheres, ready for use; 0.2molSr(NO 3 ) 2 , 0.03mol BaCO 3 , 0.6mol deionized water is placed in the reactor, and 0.04molEu 2 o 3 Dissolve in 30ml of dilute nitric acid solution with a mass concentration of 35%. 2 o 3 After complete dissolution, the Eu 2 o 3 Add the mixed solution of dilute nitric acid solution into the reactor and stir evenly, further add 0.08mol ethylenediaminetetraacetic acid and 0.04mol polyethylene glycol into the reactor, heat to 50°C, stir the mixed solution until transparent; then put the above SiO 2 Place the micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com