A kind of graphene-modified water-based cold spray zinc coating and preparation method thereof

A graphene modification, cold spray zinc technology, used in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem of high VOC content, achieve beautiful appearance, save painting costs, and overcome difficult to handle problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

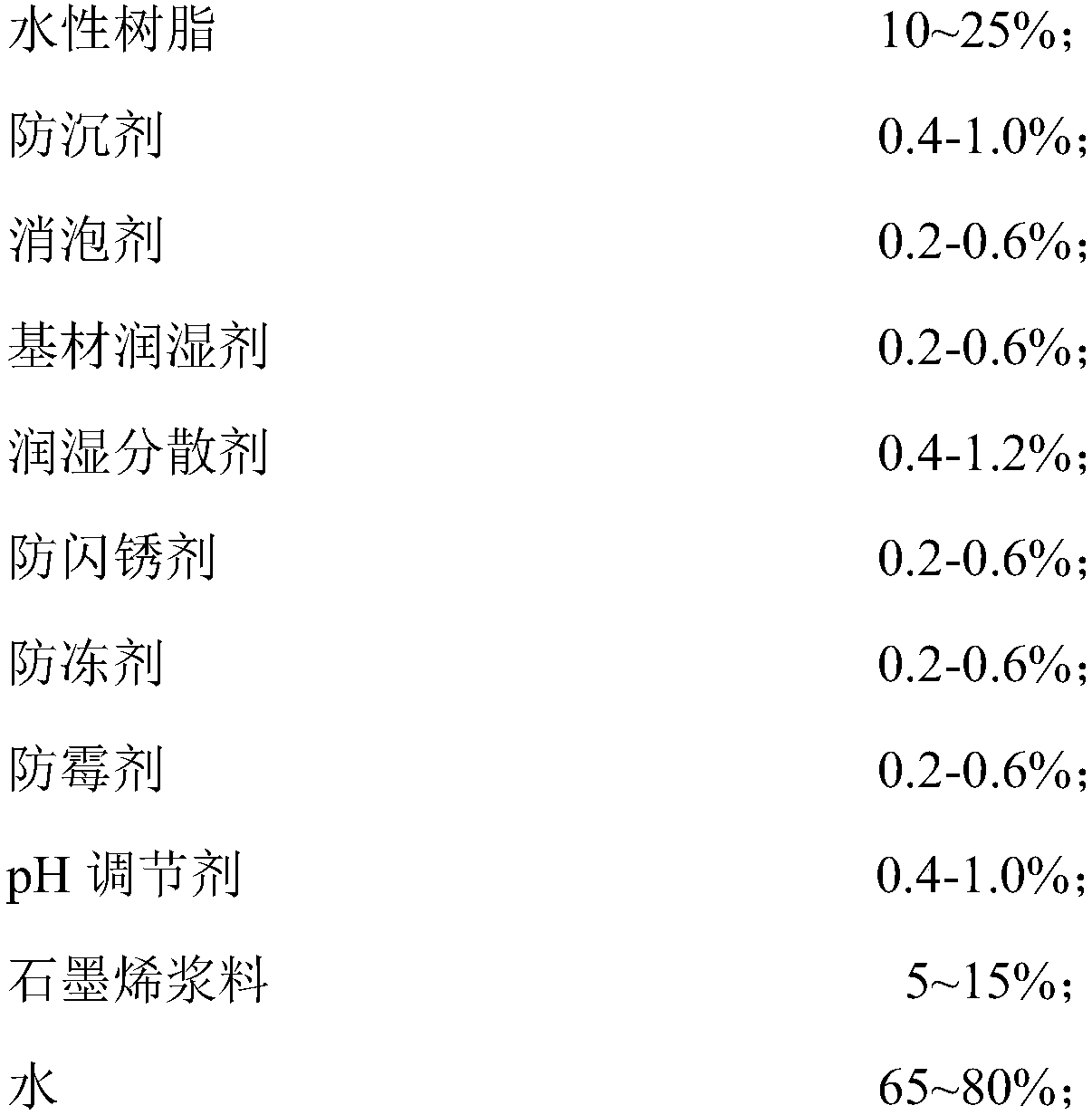

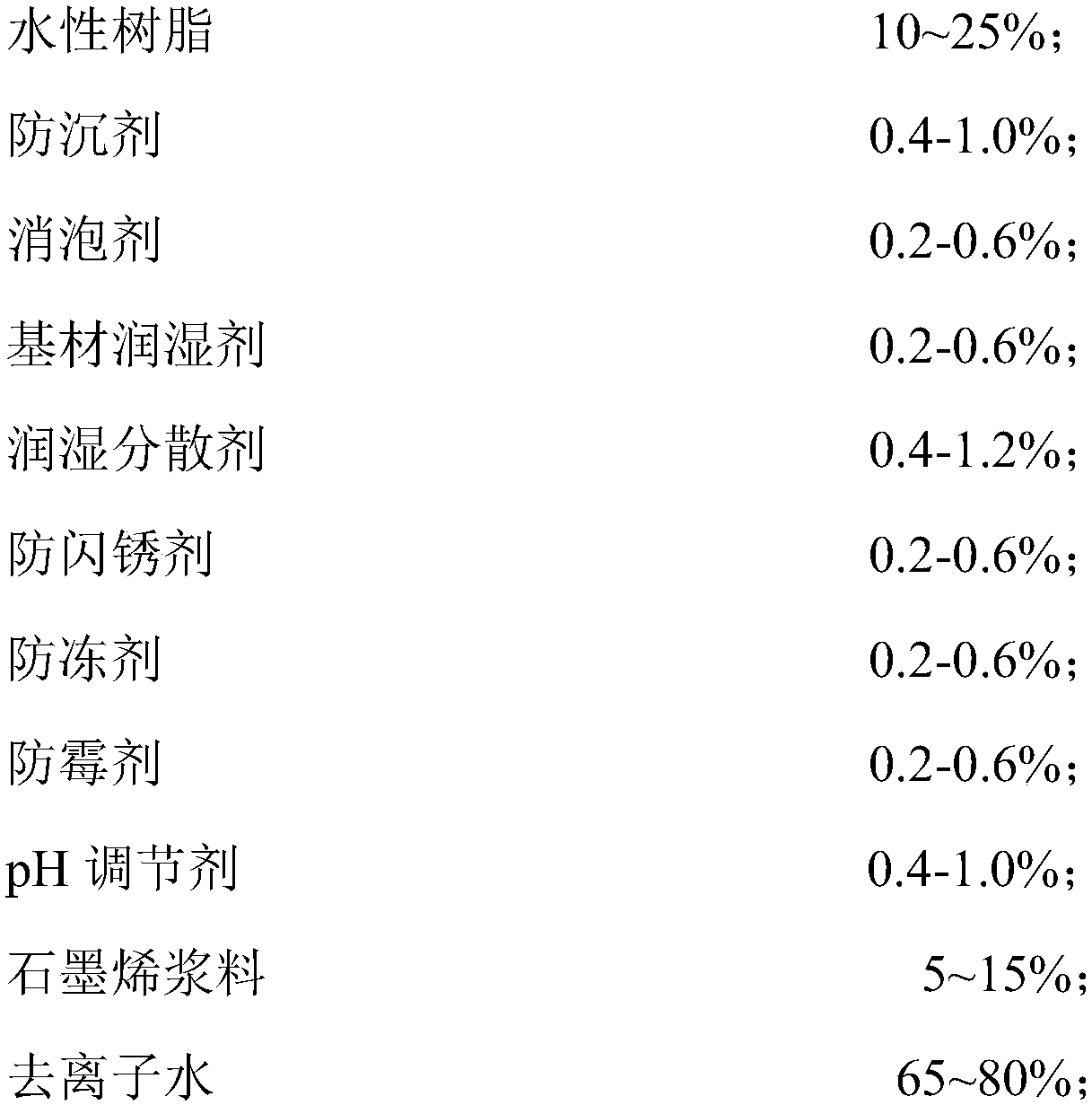

[0045] The preparation method of the graphene-modified water-based cold spray zinc paint of the present invention may further comprise the steps:

[0046] 1) Water-based resin with a mass ratio of 10-25%, 0.2-0.6% defoamer, 0.4-1.2% wetting and dispersing agent, 0.2-0.6% substrate wetting agent, 0.2-0.6% antifreeze agent, 0.2-0.6% antifungal agent, 0.2-0.6% anti-flash rust agent, 0.4-1.0% anti-settling agent, 0.4-1.0% pH regulator and 65-80% deionized water, at 600r Stir for 30min at a stirring speed of / min to disperse evenly;

[0047] 2) After adding 5-15% graphene slurry and dispersing at high speed for 30-60 minutes, a graphene-modified water-based cold-spray zinc coating A-component coating liquid is obtained;

[0048] 3) Use polysilane-modified zinc powder as component B, and slowly add component B to component A according to the mass ratio of component A and component B at a ratio of 1:4 to 1:5. Stir at a high speed for 30 min at a stirring speed of 1 / min, disperse ev...

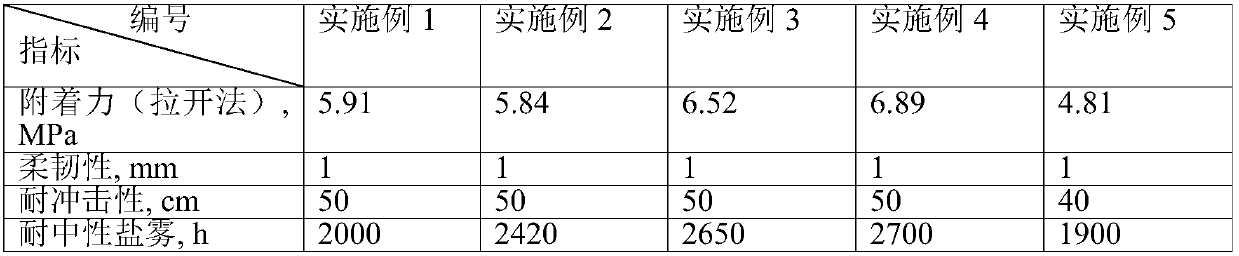

Embodiment 1

[0051] (1) Add 10% water-based polyurethane dispersion Neorez R-961 (solid content 40%), 0.6% TEGO810, 0.8% TEGO755, 0.2% TEGO4100, 0.6% ethylene glycol, 0.2% K10N, 0.6% to the batching tank 1.0% fumed silica A200, 1.0% g DMEA and 80% deionized water, stirred at 600r / min for 30min, dispersed evenly;

[0052] (2) Weigh 5% graphene slurry and disperse it in (1) for 30 minutes at a high speed of 1500r / min to obtain component A;

[0053] (3) The 600-mesh Super Fine II water-based high-purity spherical zinc powder (B component) whose surface is treated with silica fine powder according to the mass ratio of A component and B component is 1:4 is slowly mixed under mechanical stirring. Add component A and stir until there are no particles;

[0054] (4) Spray the prepared graphene-modified water-based cold-sprayed zinc paint onto the test board, and perform a performance test on the paint film after curing in a constant temperature and humidity chamber for one week. The results are s...

Embodiment 2

[0056] (1) Add 20% water-based polyurethane dispersion Neorez R-961 (solid content 50%), 0.2% TEGO901w, 1.2% TEGO750, 0.6% TEGO4100, 0.5% propylene glycol, 0.6% TROY701S, 0.5% to the batching tank 0.4% fumed silica R805, 1.0% triethylamine and 65% deionized water, stirred at 600r / min for 30min, dispersed evenly;

[0057] (2) Weigh 10% graphene slurry and disperse it in (1) for 30 minutes at a high speed of 1500r / min to obtain component A;

[0058] (3) According to the mass ratio of component A and component B of 1:5, the water-based high-purity spherical zinc powder and scaly zinc powder (spherical zinc powder: scaly zinc powder) treated with 1000 mesh silica powder Powder=99:1) (Component B) slowly add component A under mechanical stirring, and stir until there are no particles;

[0059] (4) Spray the prepared graphene-modified water-based cold-sprayed zinc paint onto the test board, and perform a performance test on the paint film after curing in a constant temperature and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com