LED-UV (light-emitting diode-ultraviolet) anti-doodling pollution-resisting coating and preparation method as well as use method thereof

An anti-graffiti and coating technology, applied in anti-fouling/underwater coatings, fire-resistant coatings, polyester coatings, etc., can solve the problems of oil-based anti-graffiti coatings with long drying time, poor VOC emission and environmental protection, and can not be used for outdoor construction. Achieve the effects of fast UV curing rate, excellent weather resistance and thermal stability, and low film-forming surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

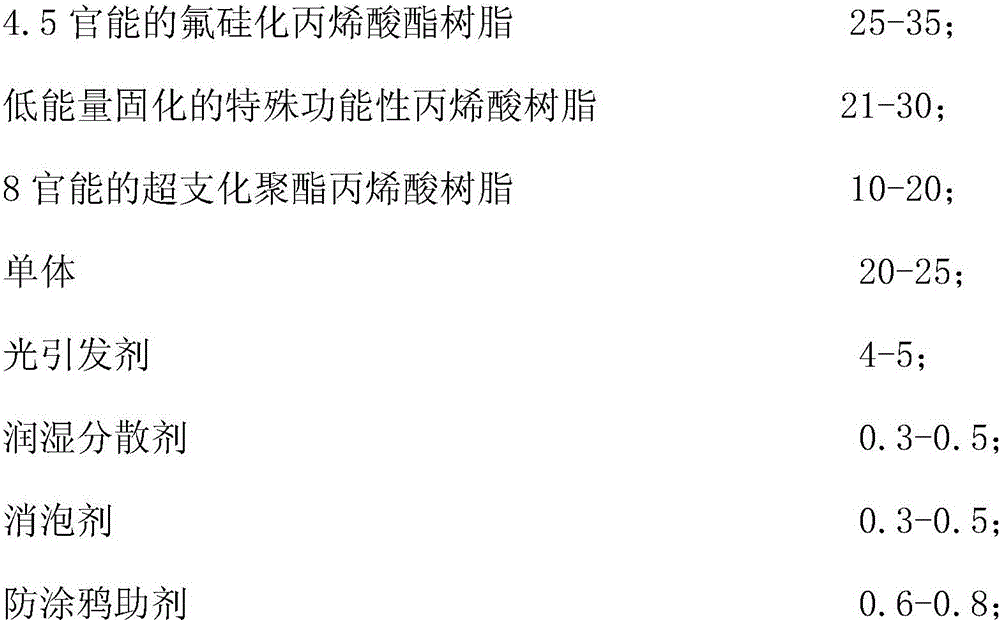

[0040] The LED-UV anti-graffiti antifouling coating of the present embodiment is made up of the component of following weight:

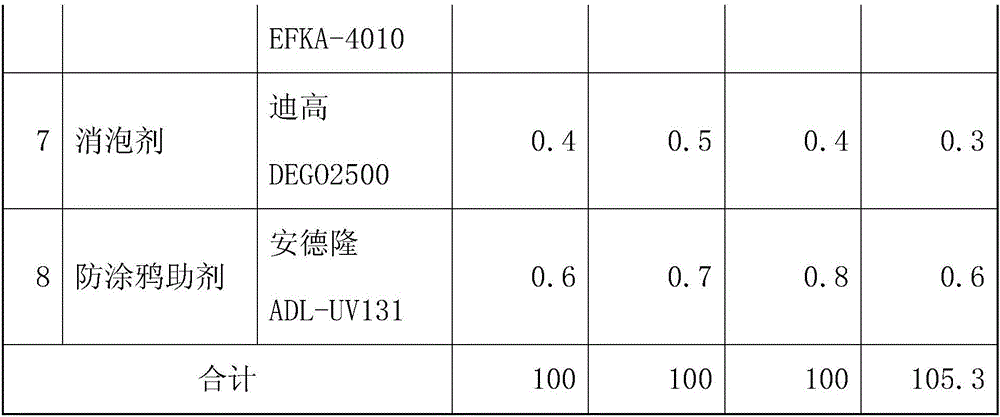

[0041] 25kg of 4.5-functional fluorine siliconized acrylate resin; 25kg of special functional acrylic resin cured by low energy; 19.7kg of 8-functional hyperbranched polyester acrylic resin; 25kg of monomer; 4kg of photoinitiator; Foaming agent 0.4kg Anti-graffiti aid 0.6kg;

[0042] Get each component by the weight shown in embodiment 1 in table 1, and preparation method is according to the following steps:

[0043] Step 1, under the condition of avoiding sunlight or ultraviolet light, add 4.5-functional fluorine siliconized acrylate resin, low-energy curing special functional acrylic resin, 8-functional hyperbranched polyester acrylic resin and monomers according to the above weight Put it in the paint container and disperse it evenly, then add photoinitiator and wetting dispersant in sequence and stir at a stirring speed of 500-800 rpm for more tha...

Embodiment 2

[0048] 28kg of 4.5-functional fluorosilicified acrylate resin; 28kg of special functional acrylic resin; 15kg of 8-functional hyperbranched polyester acrylic resin; 22.3kg of monomer; 5kg of photoinitiator; 0.5kg of wetting and dispersing agent; 0.5kg of defoamer ; Anti-graffiti aid 0.7kg;

[0049] Get each component by the weight shown in Example 2 in Table 1, repeat the preparation method described in Example 1, wherein the stirring speed is 600 rev / min in the step 1, and the stirring speed in the step 2 is 900 rev / min, then Obtain the LED-UV anti-graffiti and anti-fouling coating of the present invention, and carry out the performance detection of the paint solution.

[0050] The LED-UV anti-graffiti and anti-fouling coating is brushed or sprayed, according to 60g / m 2 The amount of coating is applied to the surface of the object to be coated (decorative exterior wall, bus stop sign, communication power facility, etc.) that has been polished and dedusted in advance. Immedia...

Embodiment 3

[0052] Get each component by the weight shown in Example 3 in Table 1, repeat the preparation method described in Example 1, wherein the stirring speed in step 1 is 700 rpm, and the stirring speed in step 2 is 1000 rpm, then Obtain the LED-UV anti-graffiti and anti-fouling coating of the present invention, and carry out the performance detection of the paint solution.

[0053] The LED-UV anti-graffiti and anti-fouling coating is applied by brushing or spraying at 70g / m 2 The amount of coating is applied to the surface of the object to be coated (decorative exterior wall, bus stop sign, communication power facility, etc.) that has been polished and dedusted in advance. Immediately after the coating is completed, the LED-UV lamp is used to irradiate and light-cure for 7 seconds. The LED-UV anti-graffiti and anti-fouling coating film in Example 3 can be obtained. The performance testing results are shown in the corresponding data of Example 3 in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com