Preparation method of fluorescent polyhedral oligomeric silsesquioxane/polymethyl methacrylate

A technology of polymethyl methacrylate and polysilsesquioxane, which is applied in the field of plastic modification, can solve problems such as poor thermal stability and poor fluorescence performance, and achieve low cost, small environmental impact, good thermal The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

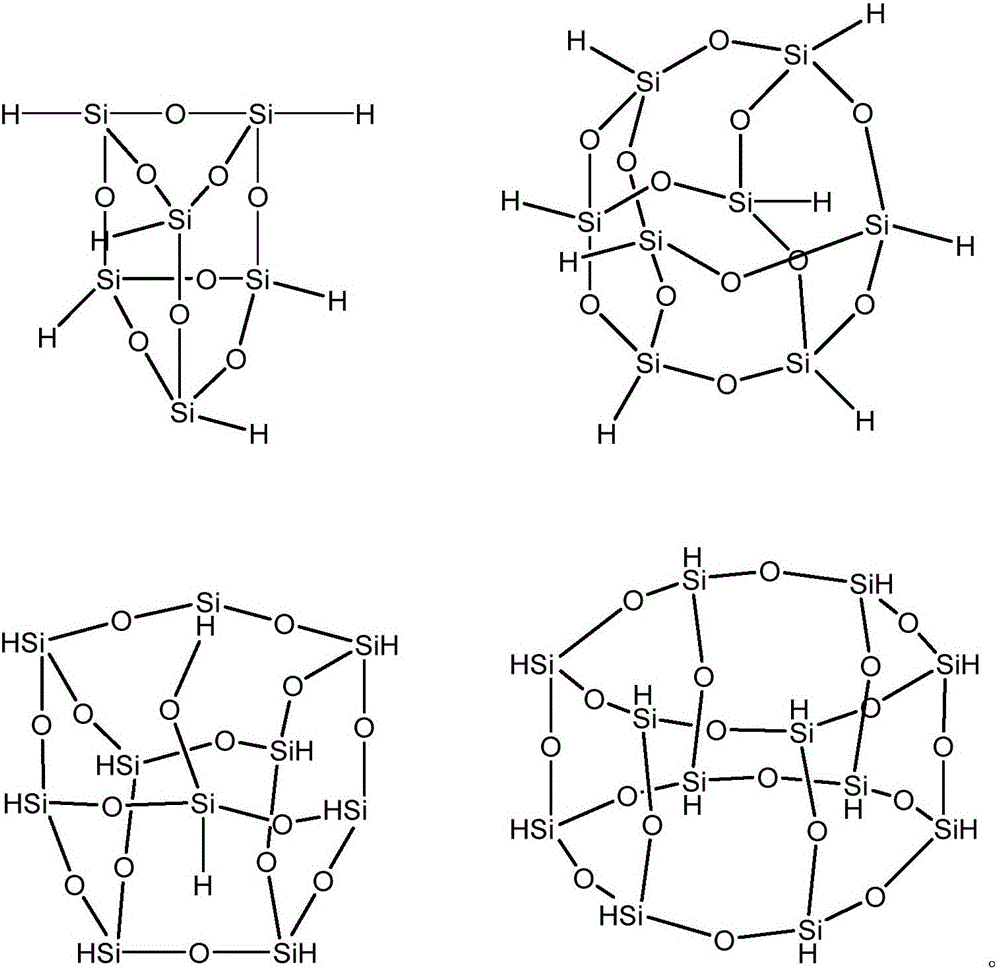

[0019] The preparation method of the fluorescent POSS modified PMMA resin provided by the invention not only endows the PMMA with fluorescent properties, but also improves the dispersibility and thermal stability of the material. The preparation method of the fluorescent POSS modified PMMA resin of the present invention comprises two steps of preparing the fluorescent POSS and the fluorescent POSS modified PMMA composite material.

[0020] In the present invention, the EMOF fluorescent agent is selected to modify the fluorescent POSS through the hydrosilylation reaction, and the hydrosilylation reaction is prepared in a nitrogen atmosphere using Schlenk technology in a double-row tube. Put POSS and EMOF into the Schlenk tube with a molar ratio of 1: (7 to 8) and a total mass of 0.3 to 0.5% of the catalyst Pt, use a double-row tube to pump nitrogen, and inject the solvent 1,4-dioxane And react at 75-83°C for 20-30h, stop heating and cool to room temperature to stop the reaction...

Embodiment 1

[0026] Put POSS and EMOF at a molar ratio of 1:7 and catalyst Pt with a total mass of 0.3% into a Schlenk tube, pump nitrogen three times with a double-row tube, inject the solvent 1,4-dioxane and cool at 75 °C Under the reaction 20h, stop heating and cool to room temperature to stop the reaction. The reaction solution was subjected to precipitation-dissolution treatment with n-hexane and THF three times in order to remove the catalyst and excess monomer in the reaction. Finally, the product was dried in a vacuum oven to constant weight and stored in a dry place.

[0027] EMOF-POSS and PMMA with a mass fraction of 0.5% were formulated into THF solutions, blended and stirred for 1 h, and vacuum-dried after the solvent was evaporated to obtain EMOF-POSS / PMMA nanocomposites with uniform dispersion of POSS and high fluorescence emission intensity. The starting temperature of material degradation is 290°C.

Embodiment 2

[0029] Put POSS and EMOF at a molar ratio of 1:8 and catalyst Pt with a total mass of 0.5% into a Schlenk tube, pump nitrogen for 3 times with a double-row tube, inject the solvent 1,4-dioxane and cool at 83 °C Under the reaction 30h, stop heating and cool to room temperature to stop the reaction. The reaction solution was subjected to precipitation-dissolution treatment with n-hexane and THF three times in order to remove the catalyst and excess monomer in the reaction. Finally, the product was dried in a vacuum oven to constant weight and stored in a dry place.

[0030] EMOF-POSS and PMMA with a mass fraction of 4.0% were formulated into THF solutions, blended and stirred for 1.5h, and then vacuum-dried after the solvent was evaporated to obtain an EMOF-POSS / PMMA nanocomposite material with uniform dispersion of POSS and high fluorescence emission intensity. The initial degradation temperature of the composite material is 295℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com