Waterproof anticorrosive colorized pre-mixed mortar

A ready-mixed mortar and anti-corrosion technology, applied in the field of ready-mixed mortar materials for construction, can solve problems such as wall cracks, secondary pollution, and difficulty in coloring, achieve strong tensile ability and compression resistance, and improve corrosion resistance. The effect of strengthening the bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

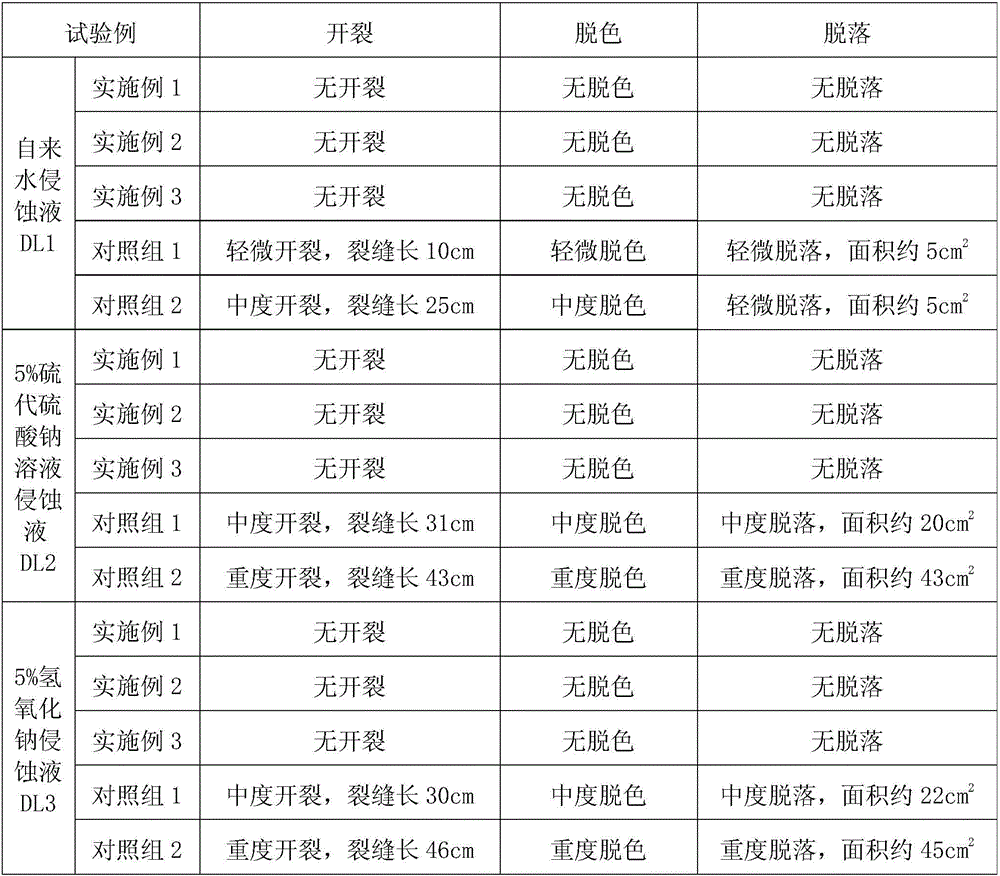

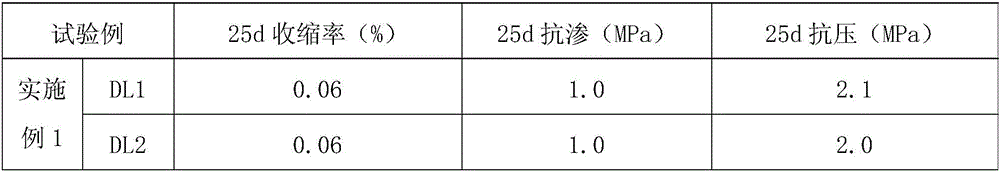

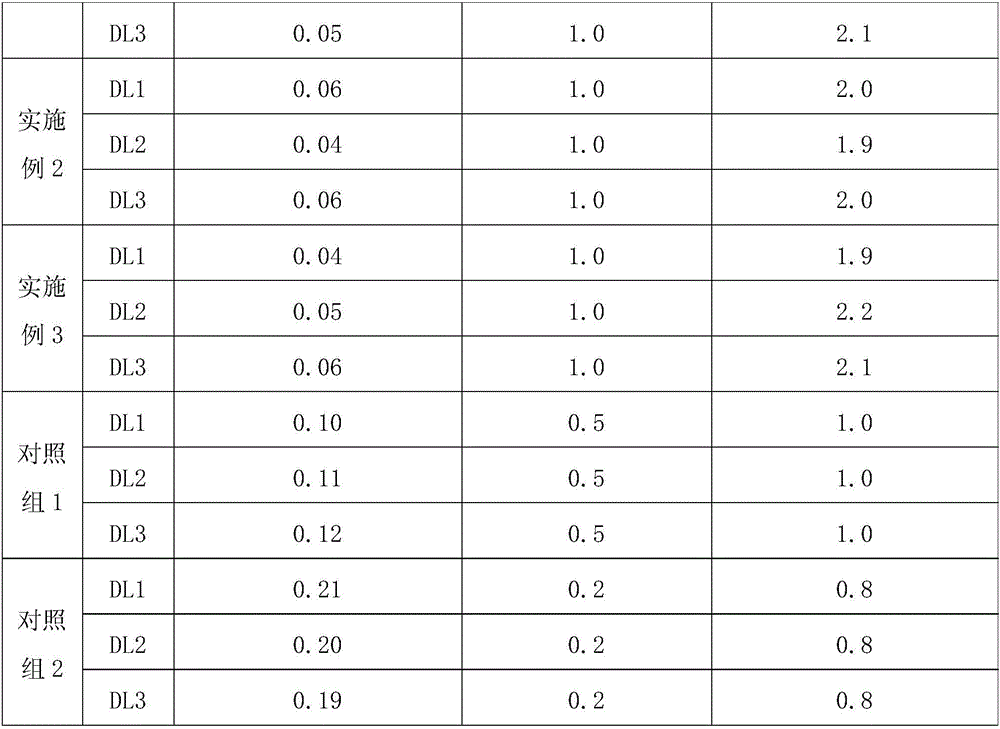

[0025] Take 10% river sand with a particle size of 0.20mm, 13% quartz sand with a particle size of 0.20mm, 15% primary fly ash, 10% granulated blast furnace slag powder, 1% polycarboxylic acid, 1 % of sodium gluconate, 20% of organic pigments, 5% of redispersible latex powder, 10% of kaolin with an average particle size of 0.5-1 μm, 5% of electrolytic manganese slag waste, and 10% of cement for stirring and mixing, adding water , after the mixing mortar is viscous, apply the mixing mortar on the 3 walls of 8 cement bricks with a brick knife, with a thickness of about 2cm. After the ready-mixed mortar is formed, use tap water and 5% Na 2 SO 4 Solution and 5% NaOH solution are sprayed on the wall respectively. After 25 days, check the quality of the wall to see if there is cracking, discoloration, or falling off. If there is falling off, measure and calculate the falling off area, and test the compression resistance of the wall Strength, impermeability strength, shrinkage.

Embodiment 2

[0027] Take 5% of river sand with a particle size of 0.40mm, 20% of quartz sand with a particle size of 0.40mm, 10% of primary fly ash, 15% of granulated blast furnace slag powder, 2% of polycarboxylic acid, 2 % of sodium gluconate, 5% of organic pigments, 15% of redispersible latex powder, 20% of kaolin with an average particle size of 0.5-1 μm, 1% of electrolytic manganese slag waste, and 5% of cement for stirring and mixing, adding water , after the mixing mortar is viscous, apply the mixing mortar on the 3 walls of 8 cement bricks with a brick knife, with a thickness of about 2cm. After the ready-mixed mortar is formed, use tap water and 5% Na 2 SO 4 Solution and 5% NaOH solution are sprayed on the wall respectively. After 25 days, check the quality of the wall to see if there is cracking, discoloration, or falling off. If there is falling off, measure and calculate the falling off area, and test the compression resistance of the wall Strength, impermeability strength, sh...

Embodiment 3

[0029] Take 7% of river sand with a particle size of 0.30mm, 10% of quartz sand with a particle size of 0.30mm, 13% of primary fly ash, 13% of granulated blast furnace slag powder, 1.5% of polycarboxylic acid, 1.5 % of sodium gluconate, 16% of organic pigments, 11% of redispersible latex powder, 17% of kaolin with an average particle size of 0.5-1 μm, 2% of electrolytic manganese slag waste, and 8% of cement for stirring and mixing, adding water , after the mixing mortar is viscous, apply the mixing mortar on the 3 walls of 8 cement bricks with a brick knife, with a thickness of about 2cm. After the ready-mixed mortar is formed, use tap water and 5% Na 2 SO 4 Solution and 5% NaOH solution are sprayed on the wall respectively. After 25 days, check the quality of the wall to see if there is cracking, discoloration, or falling off. If there is falling off, measure and calculate the falling off area, and test the compression resistance of the wall Strength, impermeability strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com