A kind of preparation method of yttrium zirconate ceramic microcrystalline opaque glaze with photocatalytic function

A technology of ceramic microcrystal and yttrium zirconate, applied in the field of ceramic materials, can solve the problems of affecting the aesthetics of ceramic products, unstable bonding effect, etc., achieve good surface decoration effect, improve people's living standards, and promote the effect of household environment purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

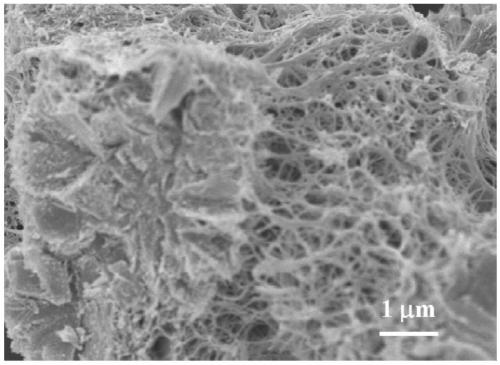

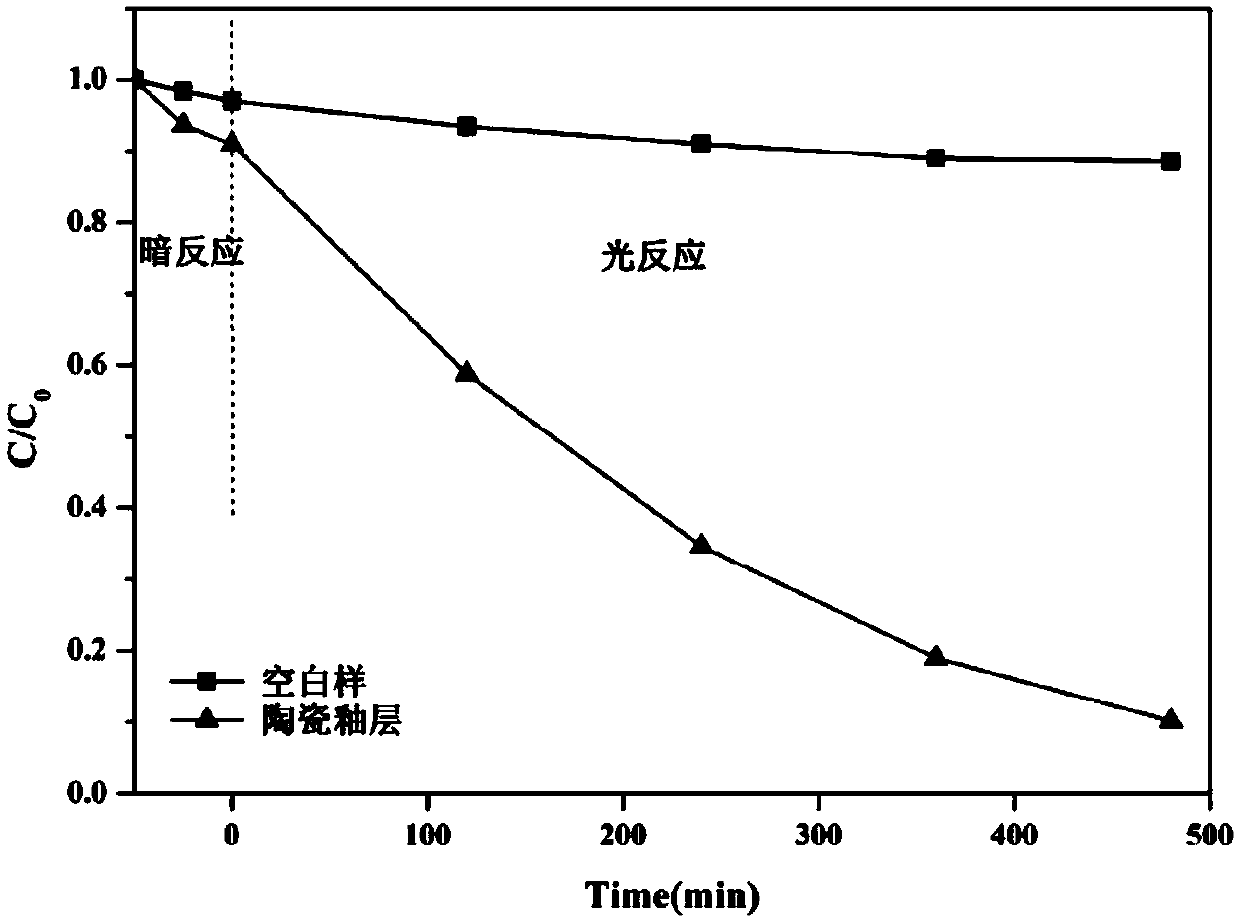

Image

Examples

Embodiment 1

[0030] 1) First, quartz, potassium feldspar, albite, borax, Y 2 o 3 , Suzhou soil, and lithium carbonate are prepared according to the following mass chemical composition ratios. SiO 2 :Al 2 o 3 :B 2 o 3 : Y 2 o 3 : Li 2 O: Na 2 O:K 2 O=57:4:22:4:7:4:3.

[0031] 2) Dry mix and grind the above-mentioned powders, pass through a 60-mesh sieve to obtain the mixture, put it into a crucible, put it into an electric furnace and keep it at 1270°C for 20 minutes, take it out and pour it into water to quench to make a frit. Take out the frit from the water, put it into a ball mill after drying, and grind it finely. The mass ratio of control material (frit): ball: water is 1:1:0.8, pass through a 250-mesh sieve after grinding for 3 hours, and dry for later use. This powder is denoted as A material.

[0032] 3) The above-mentioned material A, Y 2 o 3 , ZrO 2 And Suzhou soil is A material according to the mass ratio: Y 2 o 3 : Suzhou soil = 82:7:7 for batching, mix evenly...

Embodiment 2

[0038] 1) First, quartz, potassium feldspar, albite, borax, Y 2 o 3 , Suzhou soil, and lithium carbonate are prepared according to the following mass chemical composition ratios. SiO 2 :Al 2 o 3 :B 2 o 3 : Y 2 o 3 : Li 2 O: Na 2 O:K 2 O=58:5:23:3:6:3:2.

[0039] 2) Dry mix and grind the above-mentioned powders, pass through a 60-mesh sieve to obtain the mixture, put it into a crucible, put it into an electric furnace and keep it warm at 1280°C for 30 minutes, take it out and pour it into water to quench to make a frit. Take out the frit from the water, put it into a ball mill after drying, and grind it finely. The mass ratio of control material (frit): ball: water is 1:1:0.8, pass through a 250-mesh sieve after grinding for 3 hours, and dry for later use. This powder is denoted as A material.

[0040] 3) Combine the above material A and Y 2 o 3 , ZrO 2 And Suzhou soil is A material according to the mass ratio: Y 2 o 3 : Suzhou soil = 84: 6.5: 6 for batching, ...

Embodiment 3

[0044] 1) First, quartz, potassium feldspar, albite, borax, Y 2 o 3 , Suzhou soil, and lithium carbonate are prepared according to the following mass chemical composition ratios. SiO 2 :Al 2 o 3 :B 2 o 3 : Y 2 o 3 : Li 2 O: Na 2 O:K 2 O=59:6:24:2:5:2:1.

[0045] 2) Dry mix and grind the above-mentioned powders, pass through a 40-mesh sieve to obtain the mixture, put it into a crucible, put it in an electric furnace at 1290° C. for 40 minutes, take it out and pour it into water to quench to obtain a frit. Take the frit out of the water, put it into a ball mill after drying, and grind it finely. The mass ratio of control material (frit): ball: water is 1:1:0.8, pass through a 250-mesh sieve after grinding for 4 hours, and dry for later use. This powder is denoted as A material.

[0046] 3) The above-mentioned material A, Y 2 o 3 , ZrO 2 And Suzhou soil is A material according to the mass ratio: Y 2 o 3 : Suzhou soil = 86:6:5 for batching, mix evenly and grind i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com