Continuous dewatering and curing integrated process for mud and silt

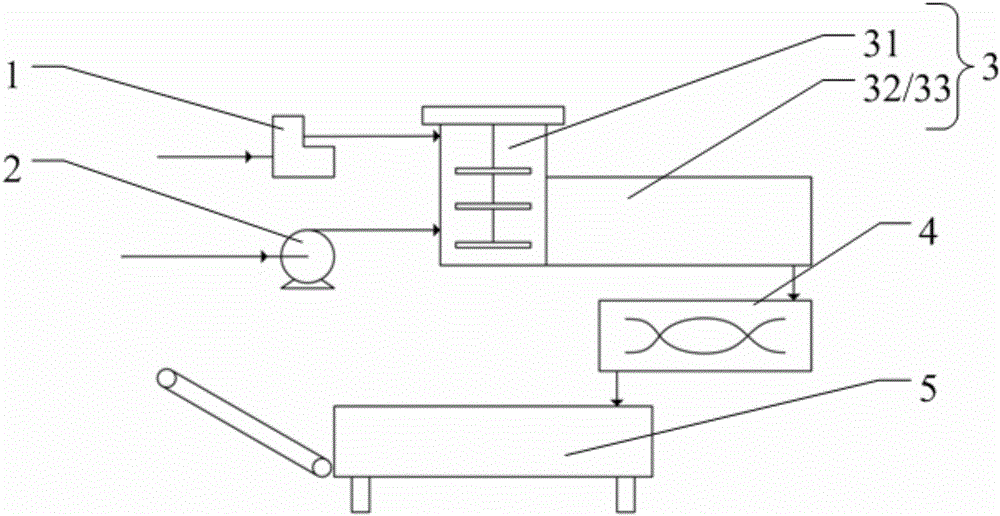

A sludge and mud technology, which is applied in the field of continuous dehydration and solidification integration of mud and sludge, can solve the problems of limited processing capacity, large volume, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0146] The mud or sludge with a water content of 70-90% is transported to the sludge conditioning tank of the thickening equipment through the sludge dosing pump through the pipeline, and at the same time, the composite flocculant aqueous solution with a concentration of 0.5-2.0‰ is passed through the additive dosing pump through the pipeline. The pipeline is transported to the sludge conditioning tank of the thickening equipment for mixing and conditioning for 30-90 seconds. Among them, the composite flocculant is in the form of solid particles, and its dosage is 0.3-1‰ of the dry mud mass. The composite flocculant includes the following components in parts by weight: 1-2 parts of chloride, 4-6 parts of polyacrylamide.

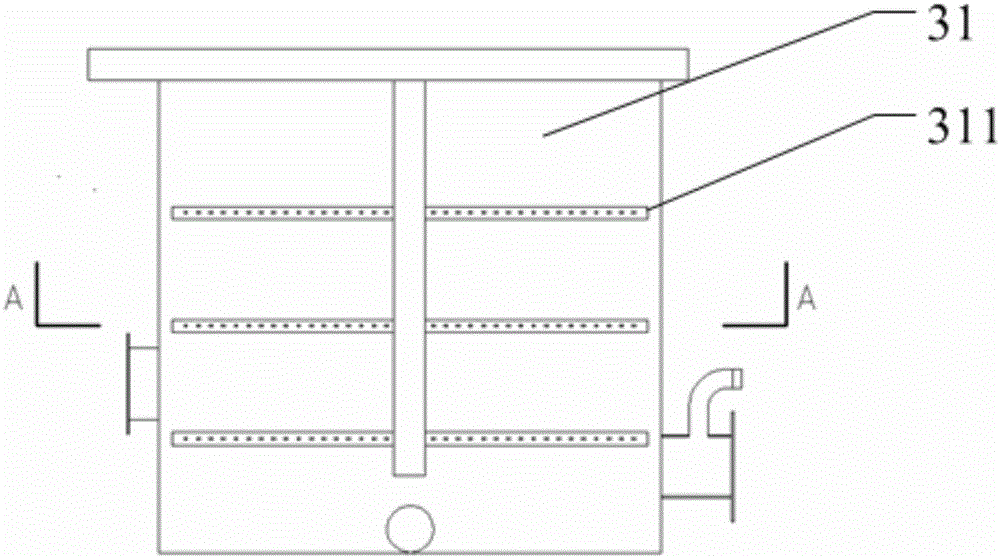

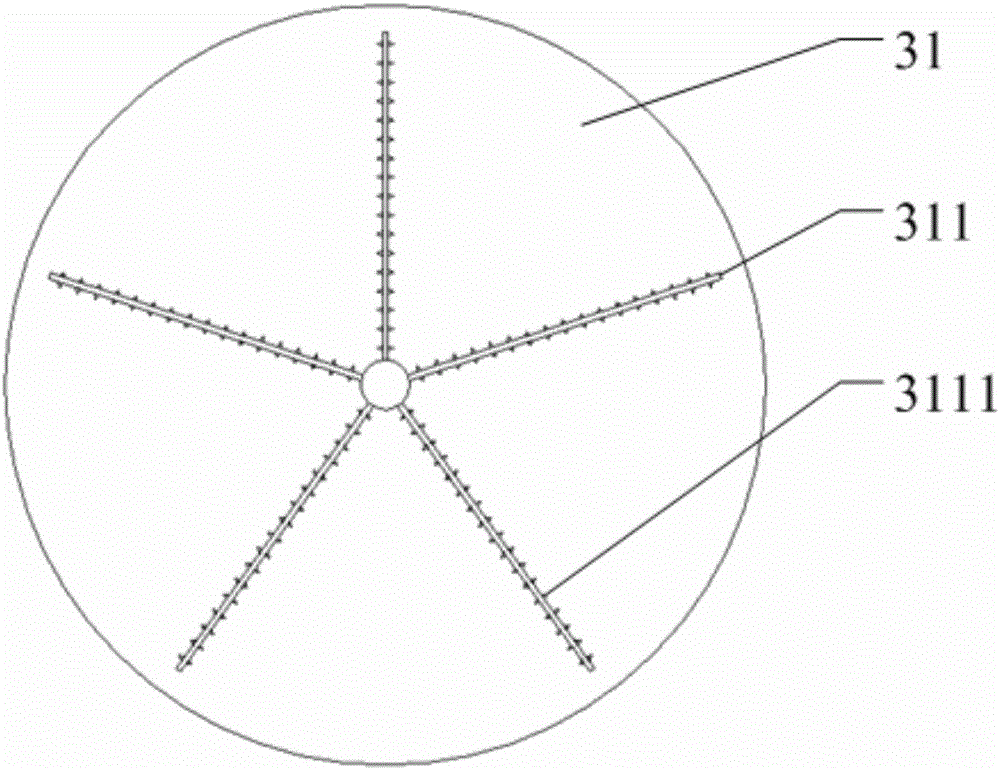

[0147] Then, the conditioned mud or sludge is flocculated into uniform fine particles with a particle size of 300-1000mm. Enter the drum type drum screen or gravity concentration dehydration structure for concentration dehydration. After concentration and d...

Embodiment 2

[0150] The construction mud with a moisture content of 75% is transported to the sludge conditioning tank of the thickening equipment through the sludge dosing pump through the pipeline, and at the same time, the composite flocculant aqueous solution with a concentration of 1‰ is transported to the thickening equipment through the pipeline through the additive dosing pump In the sludge conditioning tank, carry out mixing and conditioning for 50s. Among them, the composite flocculant is in the form of solid particles, and its dosage is 0.5‰ of the absolute dry mud mass. The composite flocculant includes the following components in parts by weight: 1 part of sodium chloride and 5 parts of polyacrylamide.

[0151] Then, after conditioning, the mud is flocculated into uniform fine particles with a particle size of 300-1000mm. Enter the drum type drum screen for concentration and dehydration. After concentration and dehydration, the moisture content of the mud is 55%, and then in...

Embodiment 3

[0154] The river sludge with a moisture content of 80% is transported to the sludge conditioning tank of the thickening equipment through the pipeline through the sludge dosing pump, and at the same time, the composite flocculant aqueous solution with a concentration of 0.5‰ is transported to the thickening equipment through the pipeline through the additive dosing pump In the sludge conditioning tank, mix and condition for 80s. Among them, the composite flocculant is in the form of solid particles, and its dosage is 1‰ of the absolute dry mud mass. The composite flocculant includes the following components in parts by weight: 2 parts of magnesium chloride and 6 parts of polyacrylamide.

[0155] Then, after conditioning, the sludge is flocculated into uniform fine particles with a particle size of 300-1000mm. Enter the gravity concentration and dehydration structure for concentration and dehydration. After concentration and dehydration, the moisture content of the sludge is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com