Method for preparing sodalite and ZSM-5 molecular sieve from fly ash acid process aluminum extraction residue and fly ash utilization method

A technology for extracting aluminum residue and ZSM-5, which is applied in the directions of borocarbonane silicone crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, alumina/aluminum hydroxide, etc., to achieve considerable environmental benefits and efficient resource utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

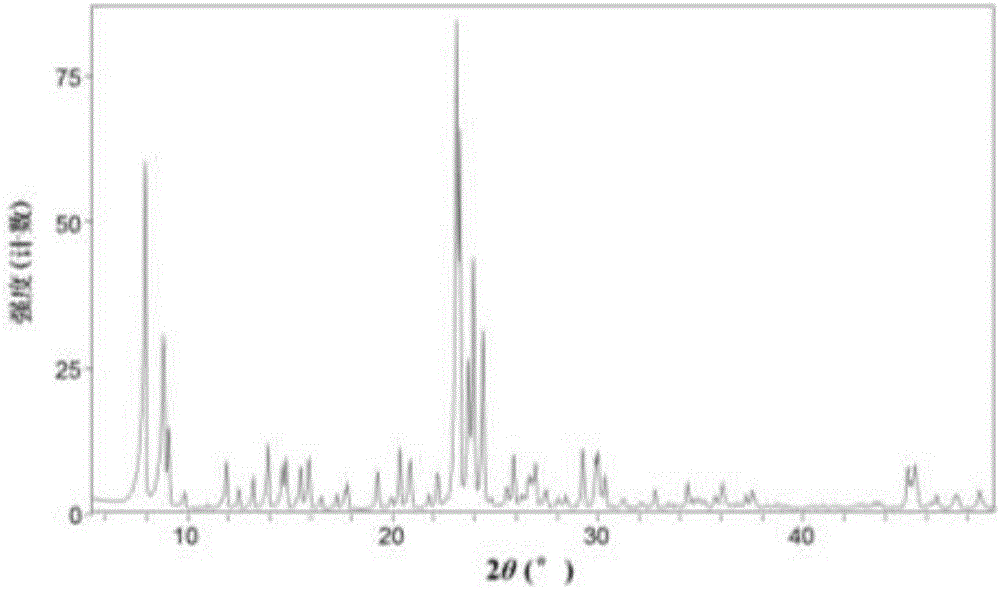

Image

Examples

preparation example

[0077] This preparation example illustrates the preparation of fly ash to obtain the aluminum extraction residue of fly ash acid method.

[0078] Take 100g of fly ash, add 5mol / L hydrochloric acid solution, stir and react at 150°C for 30min, filter and wash to obtain aluminum-rich solution and fly ash acid extraction aluminum residue. The chemical composition of the fly ash acid extraction aluminum residue is shown in Table 2.

Embodiment 1

[0080] (1) Add 50g of fly ash acid extraction aluminum residue to Na 2 CO 3 60g of solid powder, mixed and ground, roasted at 860°C for 90 minutes, cooled rapidly in air after the roasting, and crushed to below about 200 mesh to obtain roasted slag;

[0081] (2) After the roasted slag material is subjected to dry magnetic separation to remove iron, take 70g and add 140ml of deionized water (the amount of water is 200ml relative to 100g of roasted slag material) and carry out water immersion at 100°C and normal pressure for 20min, Leaching and dissolution of Na in the roasted slag 2 SiO 3 and NaAlSiO 4 , to obtain a solid-liquid mixed water immersion product; where the solid is dissolved Na 2 SiO 3 and NaAlSiO 4 The remaining product after; the liquid is containing Na 2 SiO 3 and NaAlSiO 4 The solution;

[0082] (3) Add sodium carbonate solution (recycle the second filtrate from step (6), concentration 15% by weight) 500ml in water immersion product 100g (convert to c...

Embodiment 2

[0091] (1) Add 50g of fly ash acid extraction aluminum residue to Na 2 CO 3 65g of solid powder, mixed and ground, roasted at 890°C for 100min, after the roasting was finished, quickly air-cooled, and crushed to about 180 mesh or less to obtain roasted slag;

[0092] (2) After the roasted slag material is subjected to dry magnetic separation to remove iron, take 70g and add 105ml of deionized water (the amount of water is 150ml relative to 100g of roasted slag material) and carry out water immersion at 95°C and normal pressure for 18min, Leaching and dissolution of Na in the roasted slag 2 SiO 3 and NaAlSiO 4 , to obtain a solid-liquid mixed water immersion product; where the solid is dissolved Na 2 SiO 3 and NaAlSiO 4 The remaining product after; the liquid is containing Na 2 SiO 3and NaAlSiO 4 The solution;

[0093] (3) add sodium carbonate solution (the second filtrate from step (6), concentration 20% by weight) 600ml is added in water immersion product 93g (conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com