Covering curtain with plastic steel outer tube

A technology of blinds and outer tubes, applied in the directions of transportation, packaging, vehicle parts, etc., can solve the problems of heavy weight of blinds, unfavorable energy saving and consumption reduction, and high unit price, and achieve weight reduction, light weight increase, and unit price reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

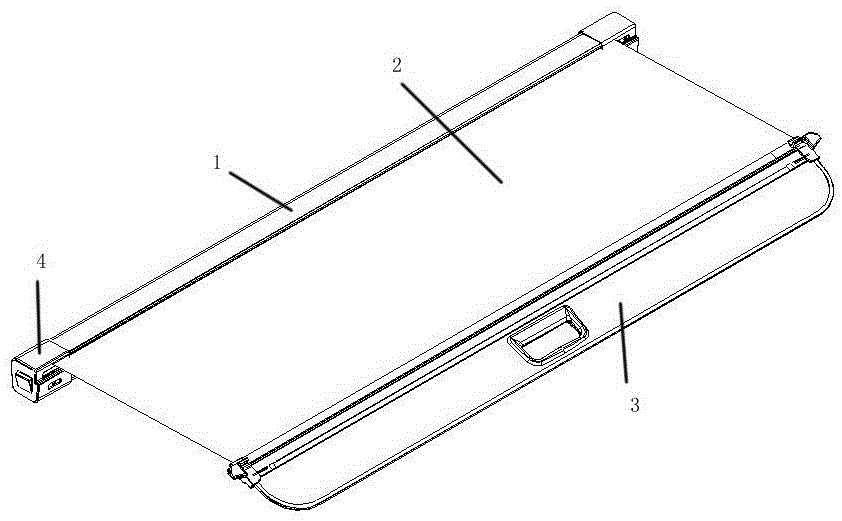

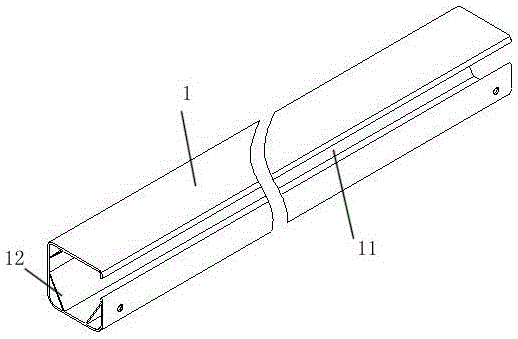

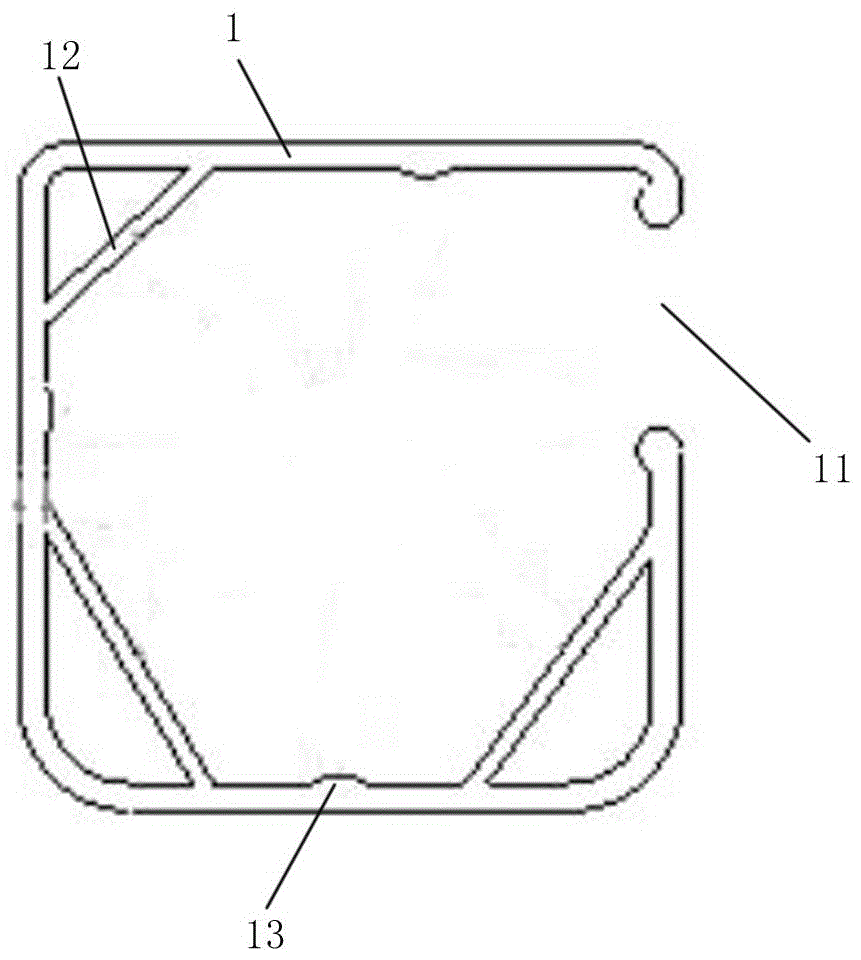

[0018] Such as Figure 1-3 As shown, a plastic-steel outer tube covering curtain includes a long cylindrical outer tube 1 and an outer cover 4 arranged at both ends of the outer tube 1, and an opening 11 is provided along the length direction of the outer tube 1, and the outer tube 1 is housed There is a retractable cloth curtain 2, and the free end of the cloth curtain 2 protruding from the opening 11 of the outer tube 1 is connected with a pull plate 3, and the outer tube 1 is a plastic steel outer tube. The plastic-steel outer tube is made of polyvinyl chloride (PVC) resin, the wall thickness of the outer tube is 1.8±0.2mm, and the density of the plastic-steel outer tube is 1.42g / cm 3 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com