Infinitely variable transmission with multiple motors connected in series

A continuously variable transmission, multi-motor technology, applied in the transmission field, can solve the problems of non-compliance with new energy requirements, complex engine manufacturing, poor battery life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

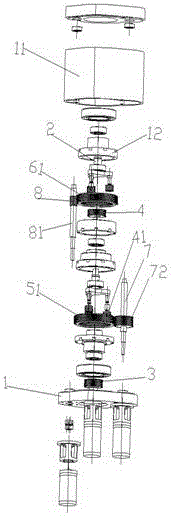

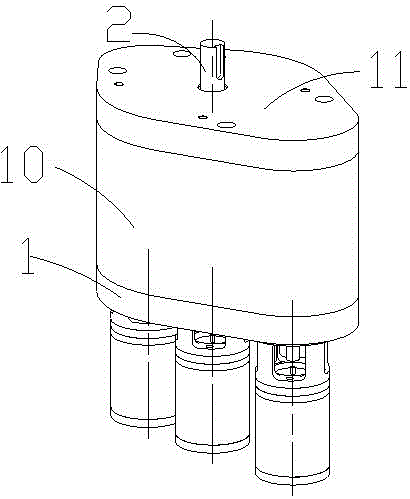

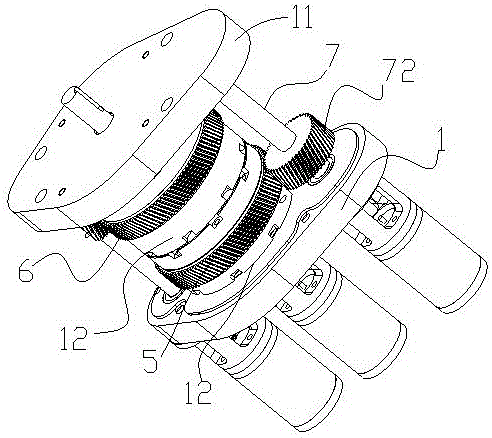

[0026] Such as Figure 1 to Figure 7 As shown, the multi-motor series continuously variable transmission provided by the present invention includes a base 1, an upper cover plate 11, and an outer shield 10, and the base 1 and the upper cover plate 11 are respectively installed on the two ends of the outer shield 10 to form an accommodating cavity, the upper cover plate 11 is provided with an output shaft 2 as an output end, and the accommodating cavity is provided with a main shaft rotation system for driving the output shaft and a plurality of side motor planetary drive systems; the main shaft rotation system includes a coaxially arranged lower planet Frame 13, the upper planet carrier 14 fixed with the above-mentioned output shaft, the first sun gear 3 located below the lower planet carrier, and the second sun gear 4 installed at the upper end of the lower planet carrier, the lower end of the first sun gear 3 is provided with a rotating shaft , the rotating shaft is set in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com