Thermal formation method of component with complex shape through martensitic steel board

A martensitic steel and complex shape technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems that it is difficult to achieve rapid and uniform quenching of martensitic steel, large mold loss, and inability to form, and achieve high The effect of engineering application value, improving component strength and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

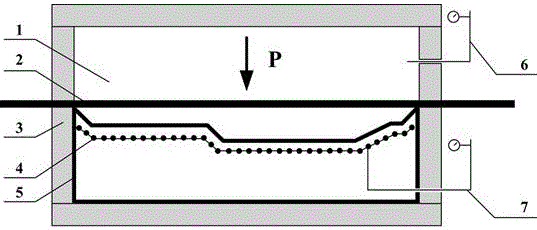

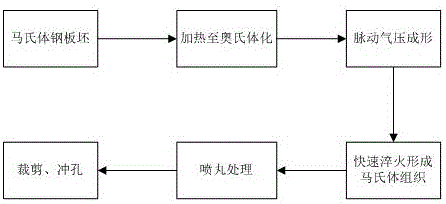

[0030] Embodiment one: with reference to attached figure 1 , 2 , Shown in 3, a kind of hot forming method of complex shape member of martensitic steel plate, comprises the following steps:

[0031] 1) Punching: Select a 0.8mm thick 40CrNiMo uncoated martensitic steel sheet and punch it to 500mm×300mm;

[0032] 2) Austenitization: Heating to 930°C through 4 zones of electric and gas mixing, using nitrogen protection, and keeping the temperature for 60s to austenitize the slab;

[0033] The advantages of using the electric hybrid heating method in the present invention are: the cost of gas heating is low, and the temperature control is not accurate; Electric hybrid heating method; through partitions, gas heating is used in the front to heat the material quickly, which is more energy-saving; electric heating is used in the rear to accurately control the heating temperature of the plate to ensure production quality. The more partitions, the better the energy-saving effect, so 4 ...

Embodiment 2

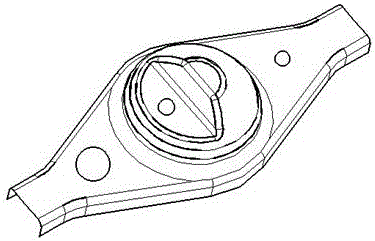

[0041] Embodiment two: with reference to attached figure 1 , 2 , Shown in 4, a kind of hot forming method of martensitic steel plate complex shape member, comprises the following steps:

[0042] 1) Punching: Select a 1.5mm thick 30CrMnSiNi2A martensitic steel plate with zinc-nickel coating, and punch it to 600mm×200mm;

[0043] 2) Austenitization: Heating to 940°C through 6 zones of electric and gas mixing, using nitrogen protection, and keeping the temperature for 200s to austenitize the slab;

[0044] 3) Pneumatic forming: put the austenitized 30CrMnSiNi2A steel plate in the pneumatic forming device, close the mold and apply the clamping force, the clamping force ranges from 50 KN to 300KN, and the controlled slab can be partially fed during the forming process ;

[0045] When the temperature of the slab is controlled to not be lower than 720°C, the upper surface of the steel plate is loaded with pulsating air pressure, the amplitude is 10MPa, the frequency is 150n / min un...

Embodiment 3

[0048]Embodiment three: with reference to attached figure 1 , 2 , Shown in 5, a kind of hot forming method of martensitic steel plate complex shape member, comprises the following steps:

[0049] 1) Punching: Select 1mm thick 22MnB5 martensitic steel plate with aluminum-silicon coating, and punch it to 700mm×500mm;

[0050] 2) Austenitization: Heating to 950°C through 6 zones of electric and gas mixing, using nitrogen protection, and holding for 150s to austenitize the slab;

[0051] 3) Pneumatic forming: put the austenitized 22MnB5 steel plate in the pneumatic forming device, close the mold and apply the clamping force, the clamping force ranges from 50 KN to 300KN, and the slab can be fully fed during the forming process ;

[0052] When the temperature of the slab is controlled to not be lower than 750°C, the upper surface of the steel plate is loaded with pulsating air pressure, the amplitude is 30MPa, the frequency is 50n / min until the steel plate is completely attached...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com