Cleaning equipment cleaning brush after cmp concentric locking structure and usage method

A post-cleaning and jointing structure technology, which is applied in the field of concentric clamping structure, can solve the problems of large concentricity deviation of the butt joints at both ends of the cleaning brush, poor cleaning effect of the card-swiping joint, and complex structure of the cleaning-swiping card joint, etc., to achieve a clamping layout Mode optimization, convenient concentric clamping and quick change, compact and concise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

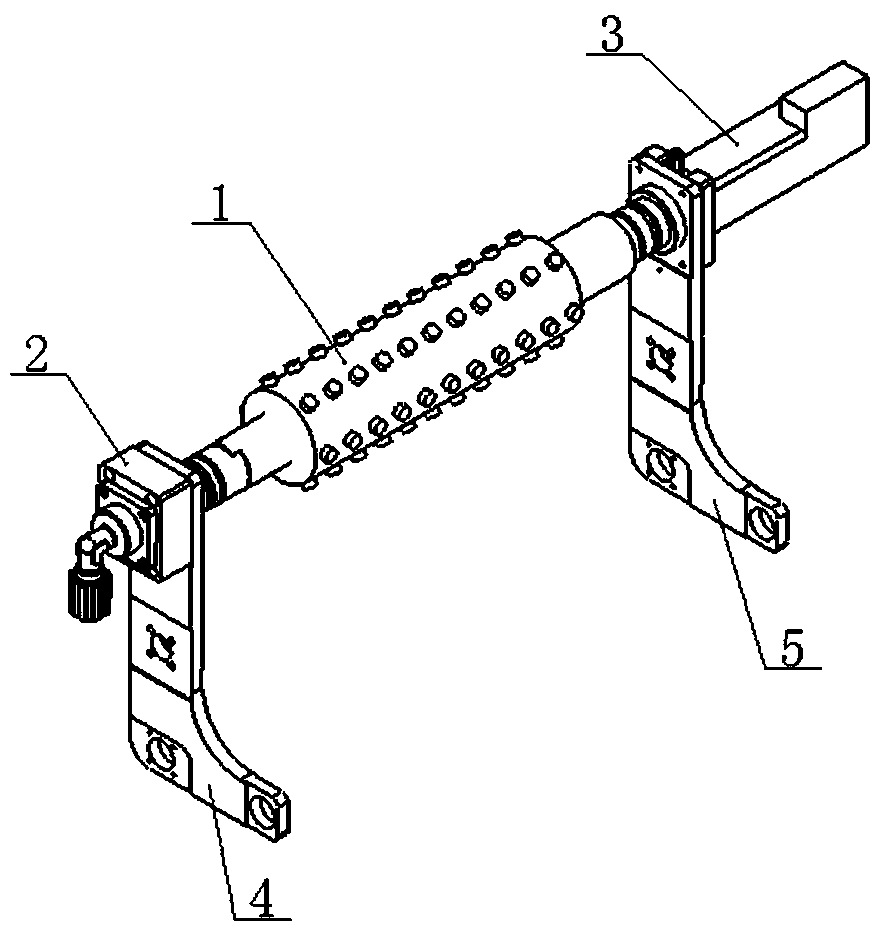

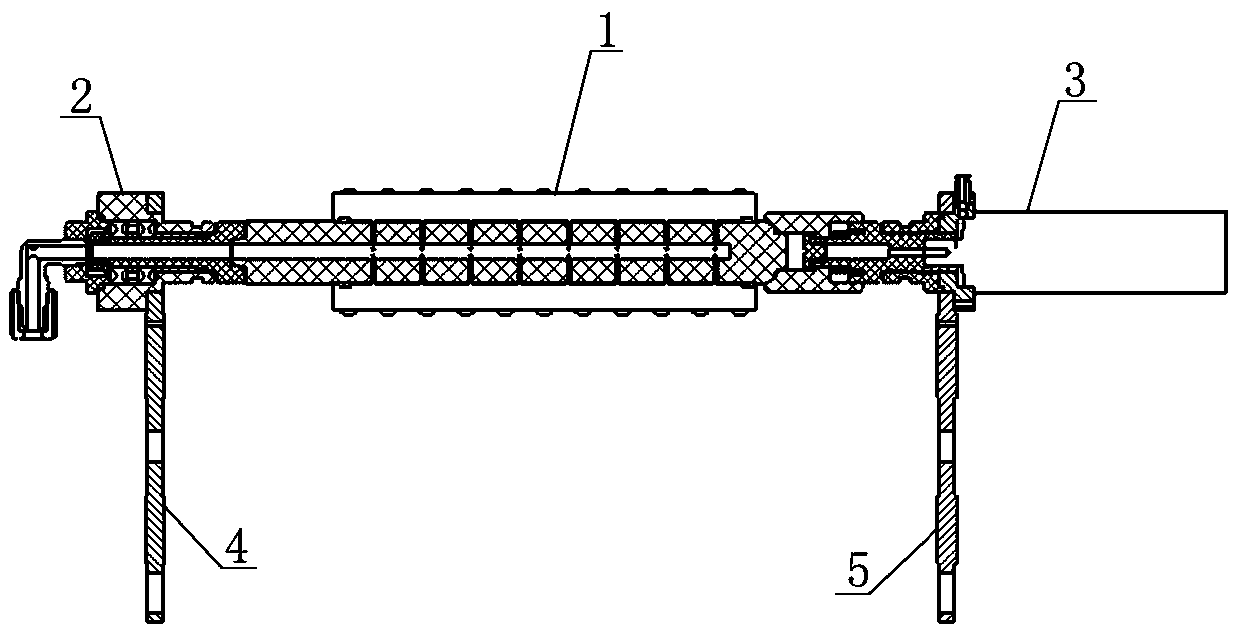

[0060] Examples see figure 1 , figure 2 As shown, the cleaning brush concentric clamping structure of this post-CMP cleaning equipment includes a cleaning brush 1, an idler shaft structure 2 that is positioned in a tapered hole with the cleaning brush 1 and transmits force in a rectangular groove, and is positioned in a tapered hole with the cleaning brush 1 and A telescopic drive shaft structure 3 with uniform force transmission in four directions, a left swing frame 4 supporting the idler shaft structure 2 and a right swing frame 5 supporting the telescopic drive shaft structure 3. The left swing frame 4 is sleeved on the cavity seat 2-3 of the idle shaft structure 2. The right swing frame 5 is sleeved on the motor seat 3-4 of the retractable drive shaft structure 3.

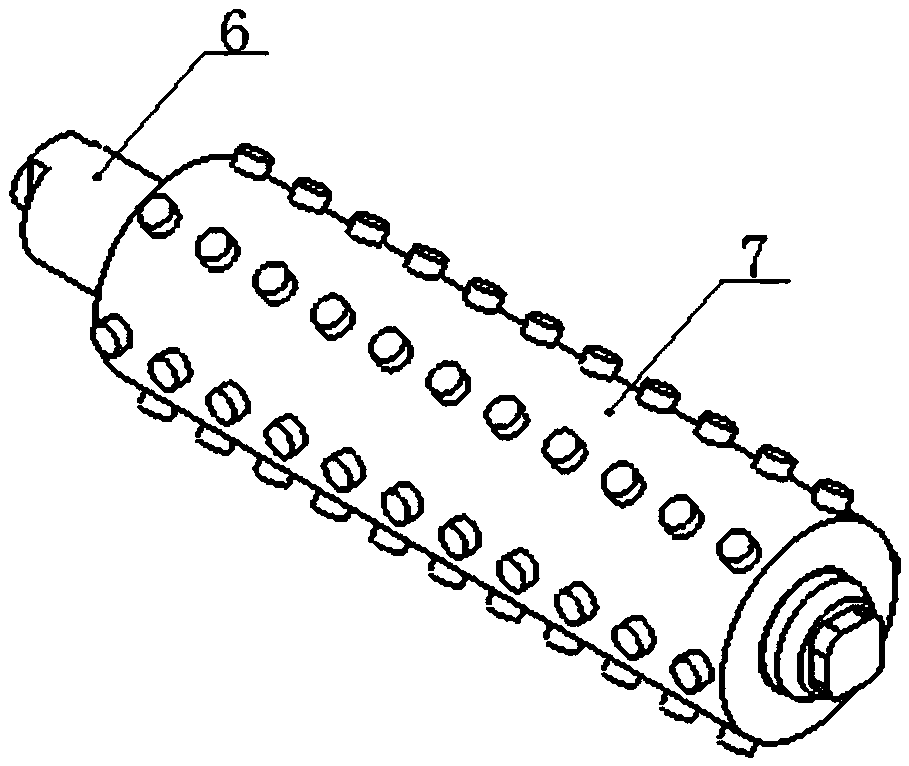

[0061] see Figure 3-5 As shown, the cleaning brush 1 includes a brush shaft 6 and a brush 7 sleeved on the brush shaft 6; the right end of the brush shaft 6 has a centering cone shaft 6.1 and a square sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com