Balanced material adjusting structure applied to corn germ selector

A technology to balance materials and adjust structure, which is applied in solid separation, sieve, grid, etc., can solve problems such as low purity, less extraction of corn germ, and uneven distribution, so as to reduce perforation area, increase extraction rate, and balance materials The effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

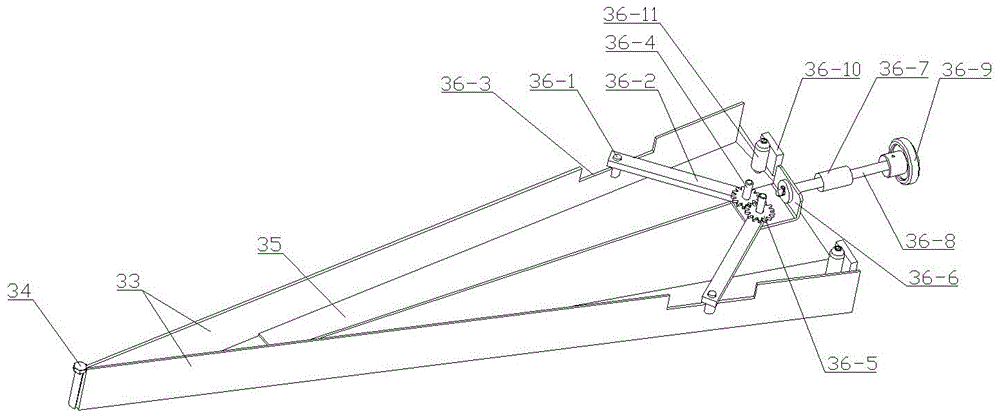

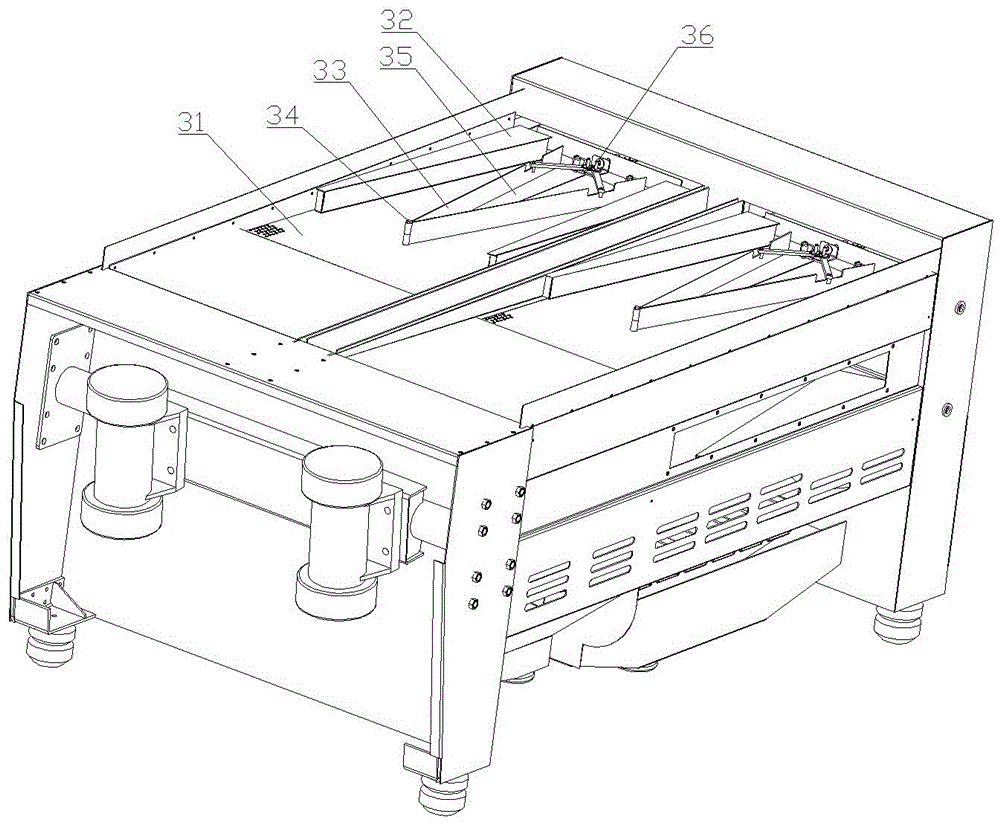

[0020] as attached figure 1 and 2 As shown, a balanced material adjustment structure applied to a corn embryo selection machine includes a hinge shaft 34 connected to the screen surface 31 of the embryo selection machine, a middle seasoning station plate 33 whose front end is hinged on the hinge shaft 34, and a middle seasoning station. The plate 33 is connected to a regulating control structure 36 . The hinged shaft 34 is located in the middle of the screen surface 31 of the embryo sorting machine, and the middle seasoning station plate 33 is located in the middle and rear section of the screen surface 31 of the embryo selection machine, that is, the second half of the material passing through the screen surface 31 of the embryo selection machine during embryo selection. part. The quantity of the seasoning station plate 33 in the described middle is two. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com