Continuous three phase mixing reactor

A reaction device, three-phase technology, applied in the field of continuous three-phase mixed reaction device, can solve the problems of high labor cost, poor consistency of finished materials, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

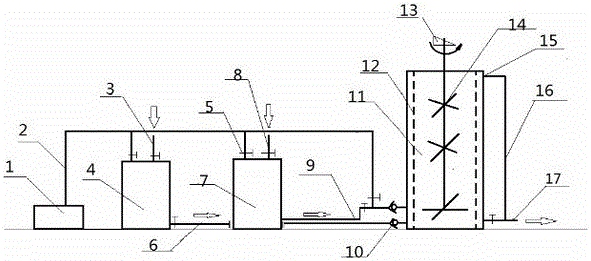

[0015] figure 1 Among them, the raw material storage equipment is a solid or solid-containing fluid storage tank 4 and a liquid material storage tank 7, and the transportation equipment 1 passes through the pressure pipe 2 and the upper part of the solid or solid-containing fluid storage tank 4 and the upper part of the liquid material storage tank 7 and the mixing reaction tank respectively. The inlet of the mixing reaction tank at the lower end of 11 is connected, and the solid (containing solids) conveying pipe 6 of the solid or solid-containing fluid storage tank 4 and the discharge pipe 9 of the liquid material storage tank 7 are respectively mixed with the mixing reaction tank at the lower end of 11 The feed inlet of the reaction tank is connected, and the overflow port 15 of the mixing reaction tank is located at the upper end of the mixing reaction tank. 3 is the inlet of the solid or solid-containing fluid storage tank 4. 5 is a valve, 8 is the feed port of the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com