Turbine handpiece provided with needle locker

A needle locker and turbine technology, which is applied in the field of medical devices, can solve problems affecting the clamping stability of the bur, easy deformation of the U-shaped bracket, and unstable clamping of the bur, so as to reduce cleaning dead angles, fix it stably, and easily The effect of installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

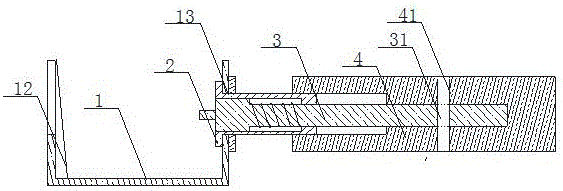

[0025] Figure 1-2 A turbine handpiece with a needle locker is shown, wherein the needle locker includes a U-shaped bracket 1, a needle sleeve 2, a thimble 3 and a sleeve 4 connected in sequence, and is characterized in that,

[0026] The sleeve 4 is radially provided with a limit hole, and the end of the thimble 3 inside the sleeve is provided with a through hole, the position of the through hole matches the position of the limit hole, and the through hole and the limit hole pass through fixed pin fixed;

[0027] The fixing pin includes a fixing part 71 and a limiting arc 72 , the fixing part 71 is a cylinder, and the limiting arc 72 is an arc connected with one end of the fixing part 71 , and the arc is adapted to the outer surface of the sleeve 4 .

Embodiment 2

[0029] Figure 1-2 A turbine handpiece with a needle locker is shown, wherein the needle locker includes a U-shaped bracket 1, a needle sleeve 2, a thimble 3 and a sleeve 4 connected in sequence, and is characterized in that,

[0030] The sleeve 4 is radially provided with a limit hole, and the end of the thimble 3 inside the sleeve is provided with a through hole, the position of the through hole matches the position of the limit hole, and the through hole and the limit hole pass through fixed pin fixed;

[0031] The fixing pin includes a fixing part 71 and a limiting arc 72, the fixing part 71 is a cylinder, and the limiting arc 72 is an arc connected to one end of the fixing part 71, and the arc is adapted to the outer surface of the sleeve 4;

[0032] Needle grooves are provided on the outer surface of the sleeve 4, and the needle grooves are adapted to the limit arc 72;

[0033] The limit arc 72 radian 120-150°;

[0034] The diameter of the fixing pin matches the diame...

Embodiment 3

[0036] Figure 1-2 A turbine handpiece with a needle locker is shown, wherein the needle locker includes a bracket 1, a thimble 3, a needle sleeve 2, a fixing needle and a sleeve 4, wherein,

[0037] The bracket 1 is U-shaped, and a round hole 13 is arranged on one side wall, and a needle sheath 2 is set inside the round hole 13;

[0038] The side wall at one end of the thimble 3 is provided with a radially outward protrusion, the diameter of the protrusion is adapted to the inner diameter of the needle sleeve 2, the thimble 3 passes through the needle sleeve so that the other end of the thimble 3 is located in the sleeve 4, the sleeve 4 The inner wall of the cylinder 4 is provided with an annular limiting part, and the diameter of the thimble 3 is adapted to the inner diameter of the annular limiting part;

[0039] The sleeve 4 is provided with a limiting hole in the radial direction, and the other end of the thimble 3 is provided with a through hole in the radial direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com