Method for rapidly preparing dried bitter melons

A technology for drying bitter gourd and bitter gourd, which is applied in the field of rapid preparation of dry bitter gourd, can solve the problems of low economic benefit, long duration and high production cost, and achieves the effects of high quality product rate, suitable greening temperature and suitable greening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

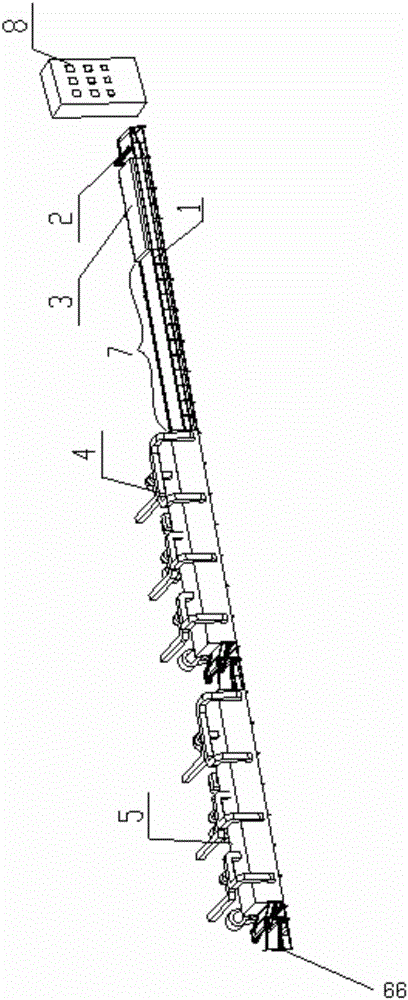

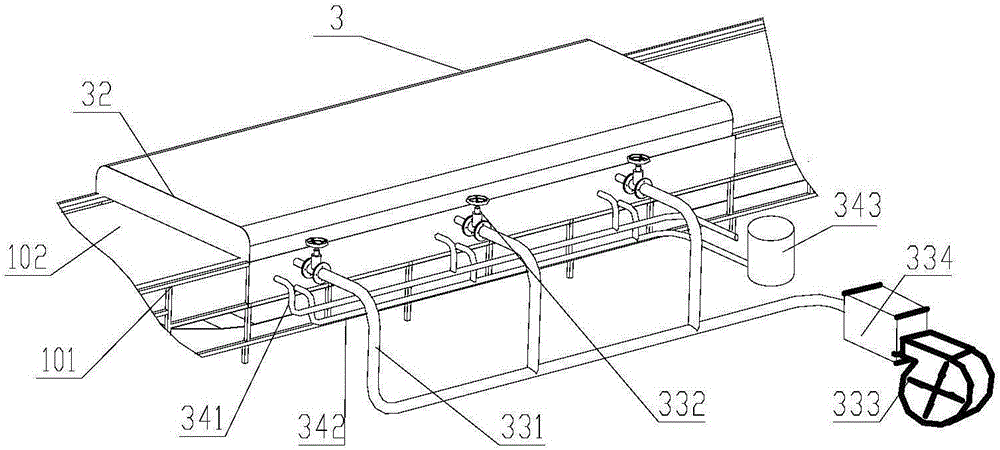

[0070] figure 1 The drying processing line in is a preferred embodiment of the present invention, and specifically includes a material conveying system 1, a material feeding finishing device 2, a greening device 3, a primary drying device 4, a secondary drying device 5, a cooling section 7 and a control system , in which the feeding finishing system 2, de-greening device 3, moisture regain sprayer 66, cooling section 7, primary drying device 4, and secondary drying device 5 are sequentially arranged on the material conveying system 1 along the conveying direction of the material.

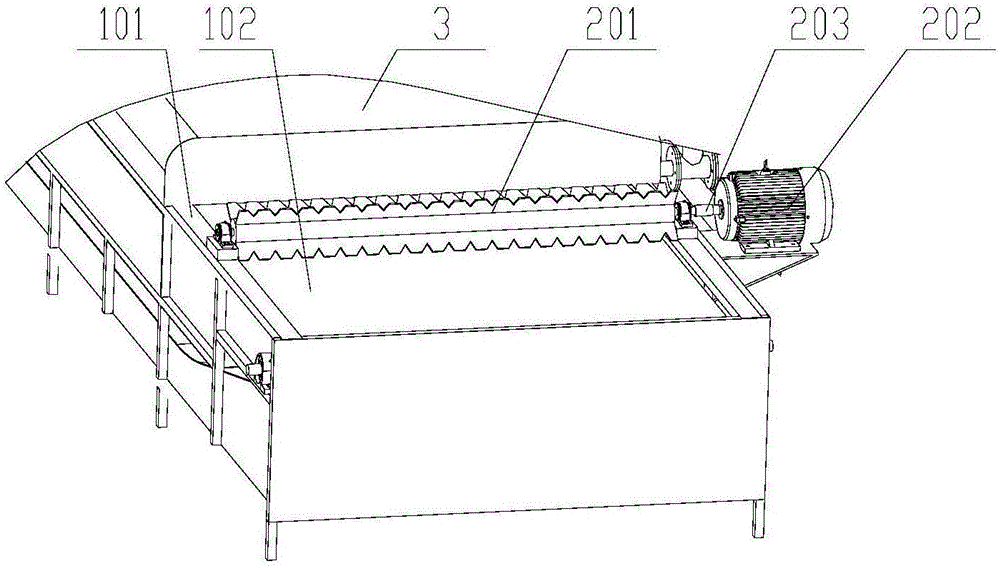

[0071] Specifically as figure 2 As shown, the feeding and sorting device 2 in this embodiment includes a toothed rake roller 201 horizontally arranged at the feeding end of the conveyor belt. The toothed rake roller 201 is installed above the conveyor belt of the material conveying system 1 through a bearing bracket. One end is connected to the feed sorting motor 202 through a coupling 203, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com