Zirconium oxide, zirconium oxide dispersion liquid, zirconium oxide-containing composition, coating film and display device

A technology for display devices and zirconia, applied in the fields of coating films and display devices, zirconia, zirconia dispersions, and zirconia-containing compositions, can solve problems such as decreased transparency or smoothness, and achieve excellent long-term storage stability , the effect of excellent visibility and excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0137] To a 0.6M zirconium oxychloride aqueous solution (700 ml) heated to 85° C., a 15 mass % ammonium sulfate aqueous solution was added over 5 minutes.

[0138] The addition amount of the ammonium sulfate aqueous solution to the zirconium oxychloride aqueous solution was made into the quantity which became ammonium sulfate: zirconium oxychloride=0.45:1 by molar ratio.

[0139] After the ammonium sulfate aqueous solution was added, the zirconium oxychloride aqueous solution became cloudy, so it was confirmed that water-insoluble basic zirconium sulfate was produced.

[0140] After stirring the zirconium oxychloride aqueous solution to which the ammonium sulfate aqueous solution was added for 30 minutes, 1N sodium hydroxide aqueous solution was added to this mixed solution, and the pH of the mixed solution was adjusted to 9-10.

[0141] Thereafter, the mixed solution was subjected to solid-liquid separation, and the solid content was recovered. Ne...

Embodiment 2

[0153] Repeat 5 sets of solid-liquid separation treatment and sulfate ion removal treatment, and repeat 2 times the treatment of washing the solid content recovered from the mixed solution with pure water to obtain zirconium hydroxide, except that it is carried out in the same manner as in Example 1 Thus, the zirconia of Example 2 was obtained.

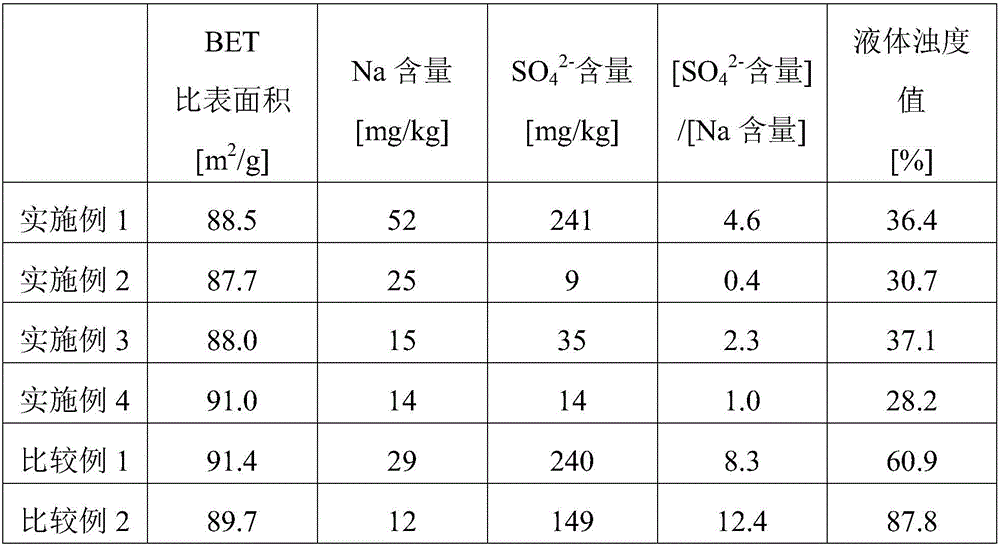

[0154] The BET specific surface area, the sulfate ion content, the sodium content, and the ratio of the sulfate ion content to the sodium content of the obtained zirconia were measured in the same manner as in Example 1. The results are shown in Table 1.

[0155] And, it carried out similarly to Example 1, and obtained the zirconia dispersion liquid of Example 2.

[0156] The liquid turbidity value of the obtained zirconia dispersion liquid was measured similarly to Example 1. The results are shown in Table 1.

Embodiment 3

[0158] Repeat 3 sets of solid-liquid separation and sulfate ion removal treatment, and repeat 3 times the process of washing the solid content recovered from the mixed solution with pure water to obtain zirconium hydroxide. Except that, carry out in the same manner as in Example 1. The zirconia of Example 3 was obtained.

[0159] The BET specific surface area, the sulfate ion content, the sodium content, and the ratio of the sulfate ion content to the sodium content of the obtained zirconia were measured in the same manner as in Example 1. The results are shown in Table 1.

[0160] And, it carried out similarly to Example 1, and obtained the zirconia dispersion liquid of Example 3.

[0161] The liquid turbidity value of the obtained zirconia dispersion liquid was measured similarly to Example 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com