Three-shaft fluxgate sensor

A fluxgate sensor and door sensor technology, applied in instruments, measuring magnetic variables, measuring devices, etc., can solve problems such as poor fluxgate sensor performance and sensor damage, achieve high consistency, reduce mass production, and shorten size and the effect of the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

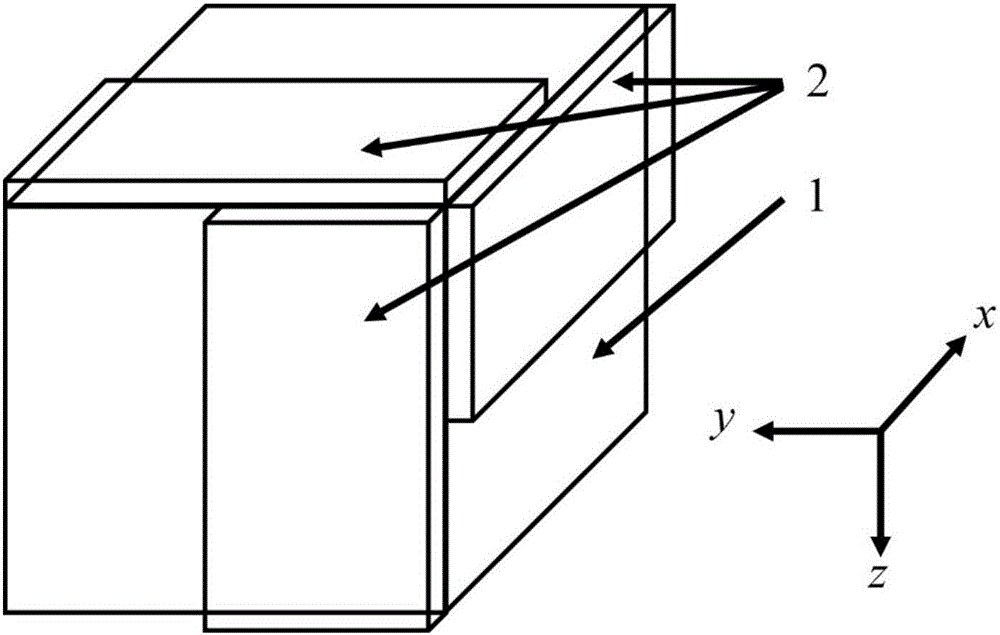

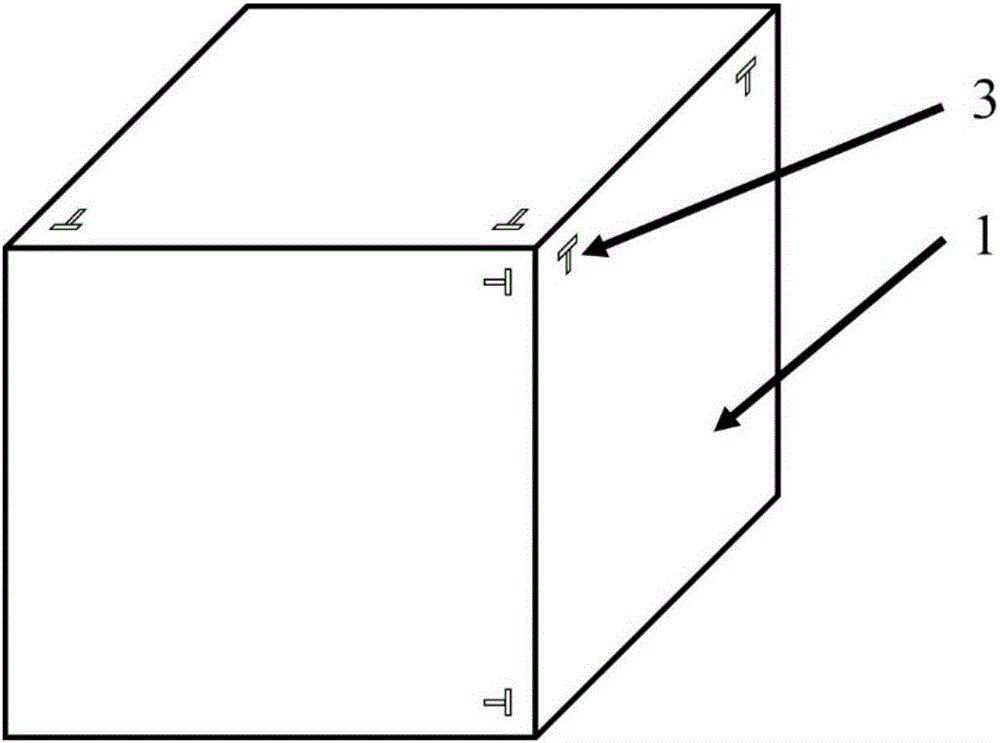

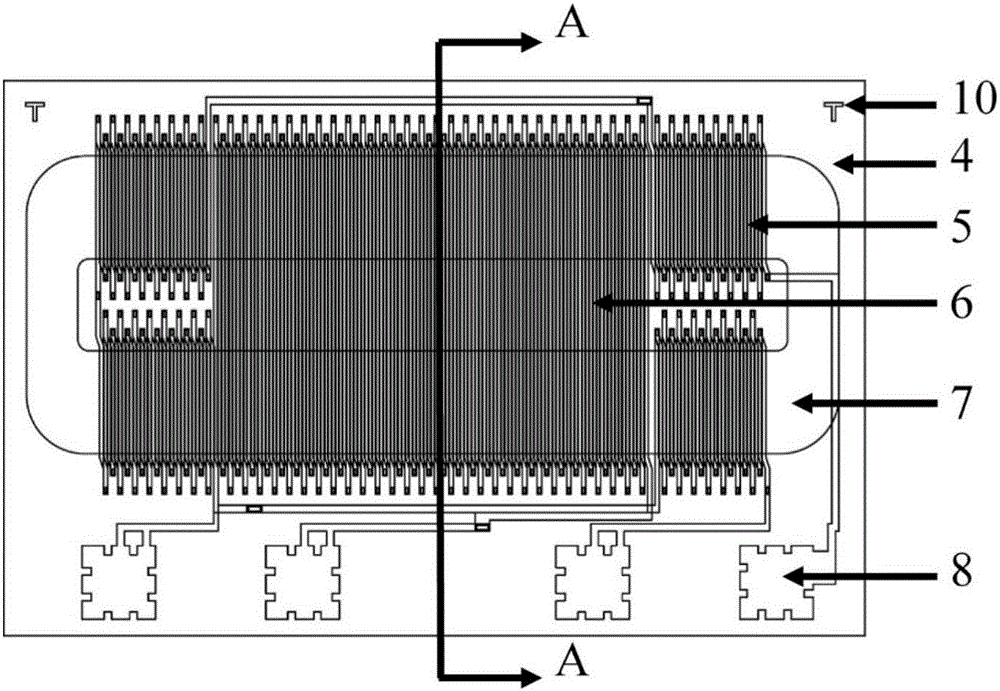

[0031] like Figure 1-4 As shown, the MEMS three-axis fluxgate sensor based on silicon cube-glass bonding of the present invention includes a silicon cube base 1, three MEMS uniaxial fluxgate sensor chips 2; wherein the MEMS uniaxial The fluxgate sensor chip 2 includes a glass substrate 4 , an excitation coil 5 , a detection coil 6 , a magnetic core 7 , electrodes 8 and a polyimide film 9 . The three 1cm*0.5cm*0.12cm microelectromechanical system uniaxial fluxgate sensor chips 2 are respectively located on three orthogonal planes with common vertices of the 1cm*1cm*1cm silicon cube base 1, and are bonded by silicon-glass Technology uses silicon bonding positioning alignment symbol 3 and copper bonding positioning alignment symbol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com