Machine vision-based method for conducting color quantization of colored bottle cap image

A color quantification and machine vision technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as the reduction of detection accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

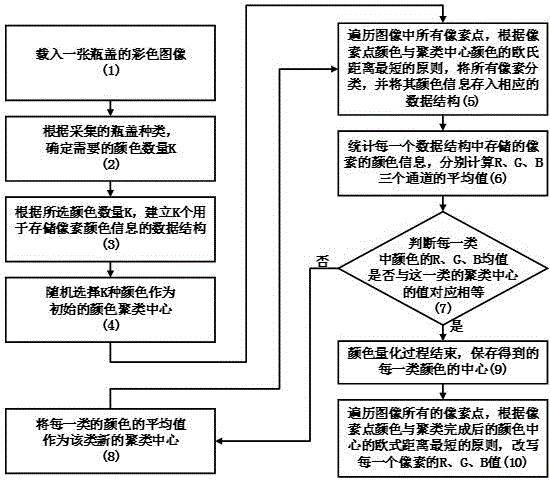

[0025] Such as figure 1 As shown, a method for quantifying the color of a color bottle cap image based on machine vision includes the following steps:

[0026] Step 1. Collect a color image of a bottle cap;

[0027] Step 2. Determine the number of colors K that needs to be quantified according to the displayed color image and actual detection needs; generally, the K value is greater than 2 and less than 30;

[0028] Step 3. According to the selected color number K, establish K data structures (including but not limited to LIST structure) for storing pixel color information;

[0029] Step 4. Randomly select K colors as the initial color cluster center;

[0030] Step 5. Traverse all the pixels in the image. According to the principle of the shortest Euclidean distance between the color of the pixel and the color of the cluster center, classify the colors of all pixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com