Rub-impact sound emission fault diagnosis method based on empirical wavelet transformation

An empirical wavelet and fault diagnosis technology, applied in the measurement of ultrasonic/sonic/infrasonic waves, measurement devices, instruments, etc., can solve the problems of signal modal aliasing, time-consuming, and the orthogonality of modal components needs to be demonstrated, and achieve elimination. The effect of modal aliasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

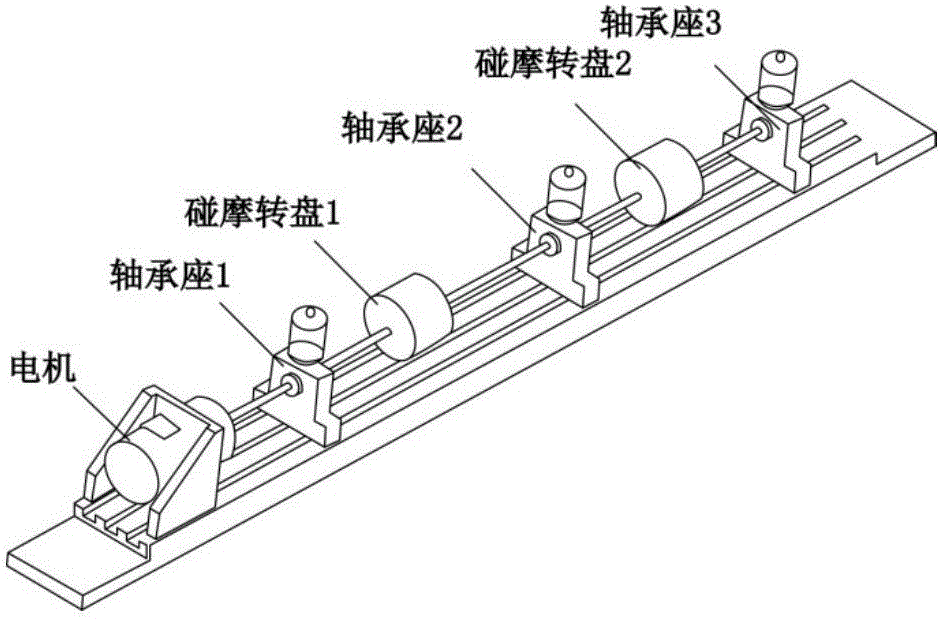

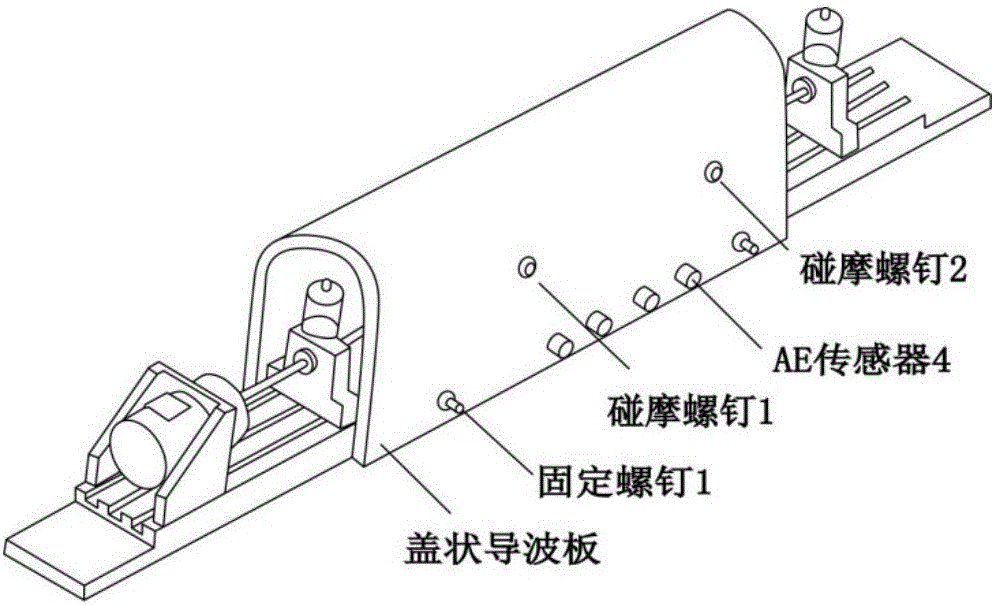

[0045] The rubbing acoustic emission experimental system consists of a rotor rubbing test bench, a sensor, a preamplifier, a governor and an acoustic emission acquisition system. As shown in Figure 1, the rotor rubbing test bench is a flexible rotor test bench, which consists of three bearing seats with sliding bearings for supporting the rotor, two rubbing discs, and rubbing screws. The rubbing screw can point to the center of the rotating shaft through the screw hole on the cover-shaped waveguide plate, and is in contact with the side of the disc. When the rotor rotates at a certain speed, the adjusting rubbing screw rubs against the rubbing disk, and the rubbing acoustic emission signal generated is received by the acoustic emission sensor through the waveguide plate. By adjusting the screw-in depth of the rubbing screw to simulate different intensities of rubbing. The governor realizes the stepless speed regulation of the motor in the range of 0-10000r / min; in order to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com