Hovering soft-landing system for rocket propelling module

A rocket propulsion and recovery system technology, applied to self-propelled bombs, aircraft parts, offensive equipment, etc., can solve the problems of damage in the landing area, cost waste, non-reusable, etc., achieve economical savings, prolong service life, and realize reuse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

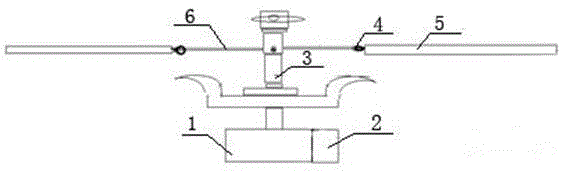

Image

Examples

Embodiment 1

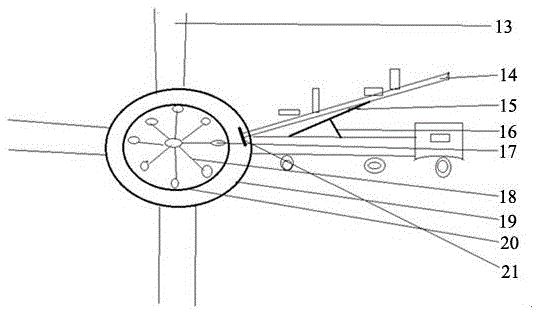

[0025] After the launch of the rocket propulsion module reaches the target airspace and separates the rocket from the star to the rocket ship, it enters the first and second stages of A deep space space recovery: a attitude adjustment stage and b unpowered vertical landing stage, (11) the attitude adjustment device starts to implement the rocket propulsion module Attitude control, (1) in the information remote control system (6) remote control to the full-angle steering gear 8 rudder stock, the directional steering gear 7 sends the rudder plate to rotate 90°, the rudder stock 12 extends out of the cabin, and the rudder plate 90° erects the command , make the (11) attitude adjustment device enter the working state, and then send to the rudder 10 full-angle steering device 8, control the cabin body rollover, control the cabin body rotation command, to deal with the influence of aerodynamic torque and rotation, so that the rocket propulsion cabin has almost no Any roll, always mai...

Embodiment 2

[0031] After the rocket propulsion cabin reaches the high-time space of B, it enters the c auxiliary device work switching stage, which is the third stage. (6) The remote control sends the steering plate to the full-angle steering device 8 directional steering device 7 rudder stock, and the rudder plate is 90° horizontally. rise, the rudder stock 12 shrinks, and the rudder plate flat rotation command shrinks the (11) attitude adjustment device into the (8) rocket cabin device room, and the explosion bolt explodes and fixes (12) the bolts of the power suspension device rotor, and utilizes aerodynamic force to let the The wing blades 5 are unfolded, and under the action of the airflow, the wing blades 5 rotate freely without power, and generate upward lift force to implement the landing deceleration of the rocket propulsion cabin.

[0032] All the other stages are the same as in Embodiment 1.

Embodiment 3

[0034] After the launch of the rocket propulsion module reaches the target airspace and the separation of the rocket from the star and the rocket ship, it enters the first and second stages of A deep-time space recovery: a stage of attitude adjustment and b stage of unpowered vertical landing. Due to inertia, the rocket propulsion module continues to fly into the air. When the lift-off potential energy is about to be zero, (1) in the information remote control system, (6) the remote control sends instructions to (12) the power suspension device, and the explosion bolt is used. The power allows the blades 5 to unfold, and under the action of the airflow, the blades 5 rotate freely without power, generating upward lift force to implement the landing deceleration of the rocket propulsion cabin.

[0035] All the other stages are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com