A Feedback Control System for Sewage Pumping Station

A technology of feedback control system and sewage pumping station, which is applied in the direction of pump control, waterway system, pump, etc., can solve the problems of peak impact, lack of regulation function, affecting use, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is specifically described below according to accompanying drawing:

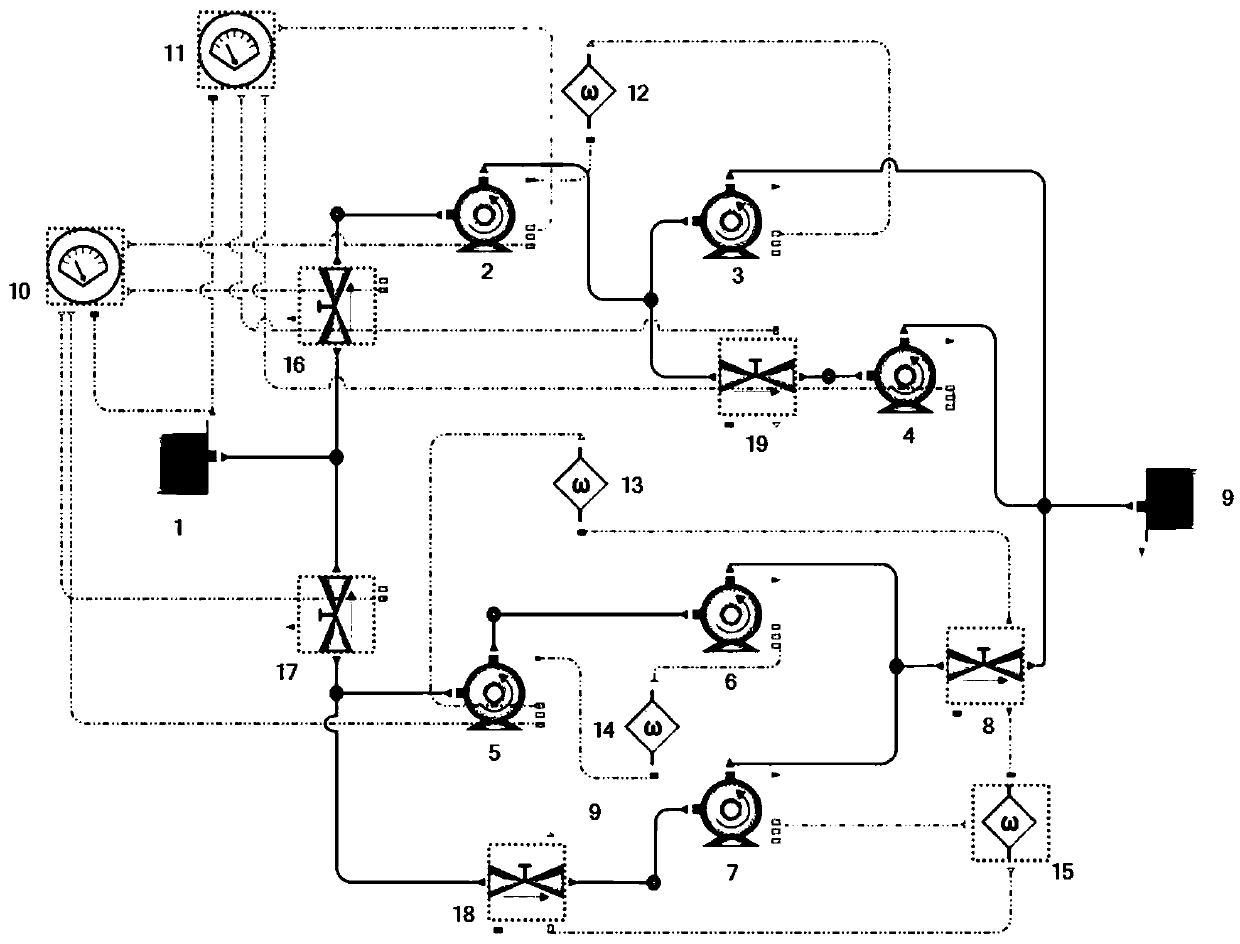

[0037] attached figure 1 Shown is a schematic structural diagram of a feedback control system for a sewage pumping station, including a sewage pool 1, a sewage concentration pool 9, and a branch 1 and a branch 2 provided between the sewage pool 1 and the sewage concentration pool 9;

[0038] Branch one is composed of control valve I16 (valve closed by default), vortex impeller sewage pump I2 and the first pump group in series; the first pump group is a parallel unit of vortex impeller sewage pump II3 and standby pump group I ; The standby pump group I is a series unit of the control valve IV19 (valve closed by default) and the vortex impeller sewage pump III4;

[0039] Branch 2 is connected with the control valve II17 (valve closed by default), then connected with the parallel unit of the second pump group and standby pump group II, and finally connected with the outlet regulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com