Fiber carrier and preparation method and application thereof

A fiber and carrier technology, applied in the field of fiber carrier and its preparation, can solve the problems of non-hydrophilicity, small voids, and low mechanical strength, and achieve the effects of large specific surface area, improved hydrophilicity, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

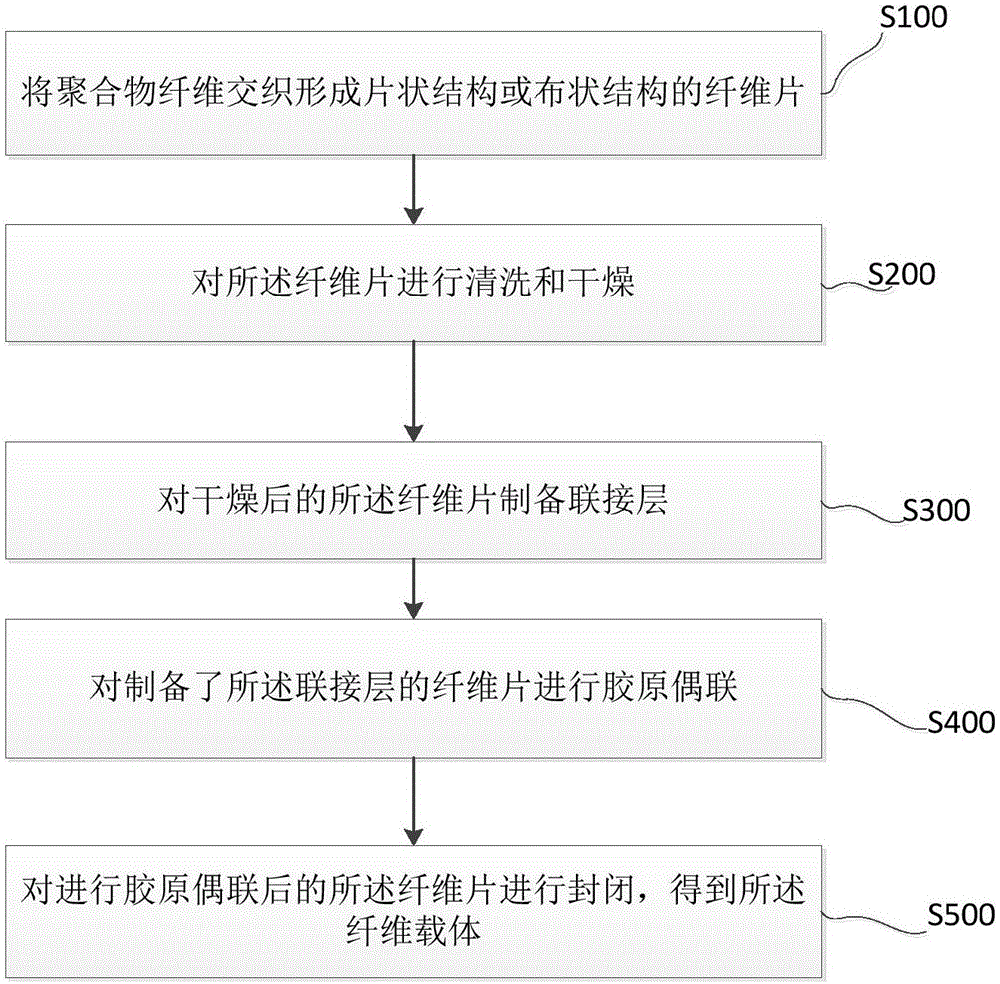

[0057] The preparation method of described fiber carrier, such as figure 1 Shown, this preparation method comprises:

[0058] S100: interweaving polymer fibers to form a fiber sheet with a sheet-like structure or a cloth-like structure.

[0059] In order to facilitate the preparation of the fiber carrier and ensure its convenient application in cell culture, it is firstly prepared into a sheet-like or cloth-like fiber sheet.

[0060] S200: Washing and drying the fiber sheet.

[0061] This step is a necessary preparatory step for the preparation of the fiber carrier. Preferably, the liquid used for cleaning is double distilled water or even ultrapure water, and the cleaning method is ultrasonic cleaning. Preferably, it is also necessary to soak the fiber sheets before cleaning to further eliminate the interference of impurities such as bacteria and microorganisms on the fiber sheets. The time is 2 to 4 hours. Preferably, the drying treatment of the washed fibers is carried ...

Embodiment 1

[0073] Preparation of fibrous carrier

[0074] Pretreatment: Select polypropylene polymer fibers with a fiber diameter of 25±2μm as raw materials, interweave them to form 30 polypropylene non-woven fiber sheets with a size of 2.5±0.2cm×0.5±0.2cm, and place 30 fiber sheets in Ultrasonic cleaning in 50ml of ultra-pure water for 10min, take out the cleaned fiber sheet and dry it with nitrogen gas. Then place it in 20ml of hydrogen peroxide solution with a volume fraction of 30% and soak for 2 hours at a temperature of 90°C, then ultrasonically clean the soaked fiber sheet with ultrapure water for 20 minutes, and dry it at 90°C for 3 hours.

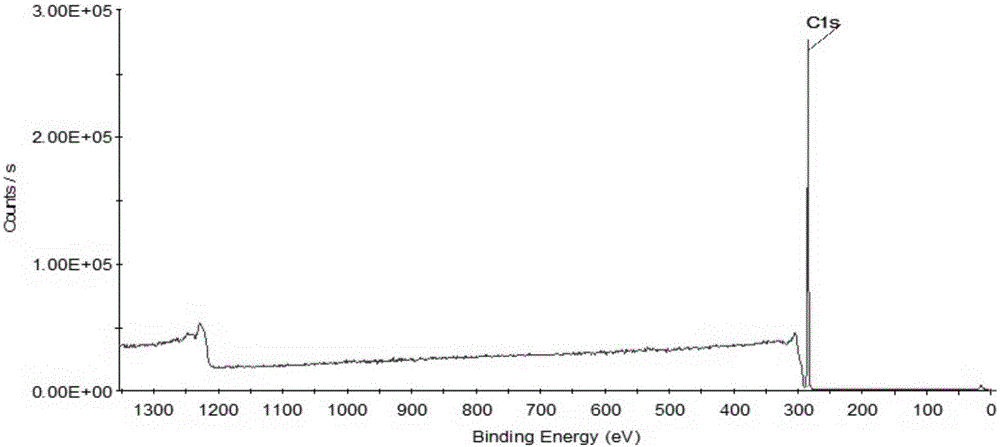

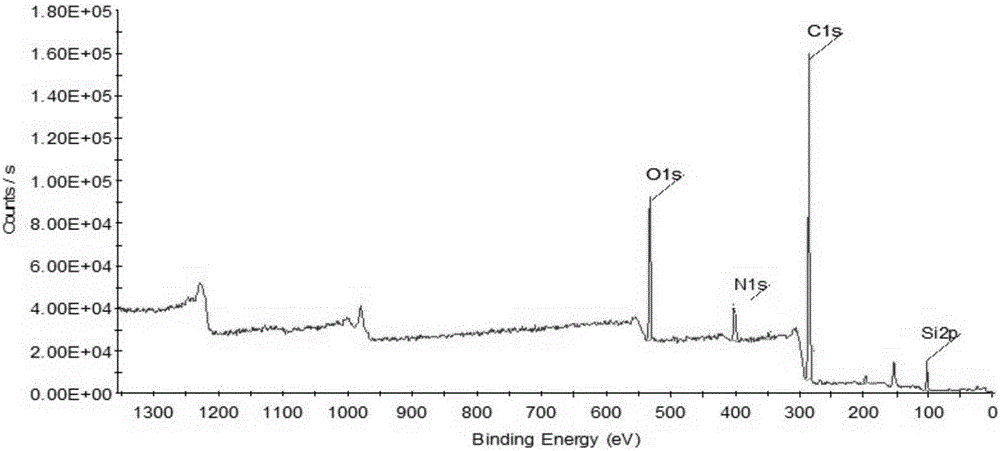

[0075] Aminosilane treatment: add the pretreated fiber sheet to a toluene solution containing 5% 3-aminopropyltriethoxysilane, take it out after the reaction, put it in the toluene solution, ultrasonically clean it for 10 minutes, and then dry it with nitrogen.

[0076] Glutaraldehyde coupling: Soak the fiber sheet treated with aminosilane i...

Embodiment 2

[0080] Preparation of fibrous carrier

[0081] Pretreatment: Select polypropylene polymer fibers with a fiber diameter of 20±2μm as raw materials, interweave them to form 30 polypropylene non-woven fiber sheets with a size of 2.5±0.2cm×0.5±0.2cm, place the fiber sheets in a 50ml supernatant Ultrasonic cleaning in pure water for 20 min, take out the cleaned fiber sheet and dry it with nitrogen gas. Then place it in 20ml of hydrogen peroxide solution with a volume fraction of 30% and soak for 3 hours at a temperature of 90°C, then ultrasonically clean the soaked fiber sheet with ultrapure water for 30 minutes, and dry it at 90°C for 4 hours.

[0082] Aminosilane treatment: Add the pretreated fiber sheet into a toluene solution containing 5% 3-aminopropyltrimethoxysilane, take it out after the reaction, place it in the toluene solution, ultrasonically clean it for 20 minutes, and then dry it with nitrogen.

[0083] Glutaraldehyde coupling: Soak the fiber sheet treated with amino...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com