Method for continuous removal of impurities in cyclohexanone

A cyclohexanone and impurity technology, applied in the field of organic chemical purification, can solve the problems that molecular sieve cannot be recycled and reused, 2-hexanone is not removed, and cannot be continuously fed, so as to achieve continuous online adsorption and desorption and product competitiveness. Strong, improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

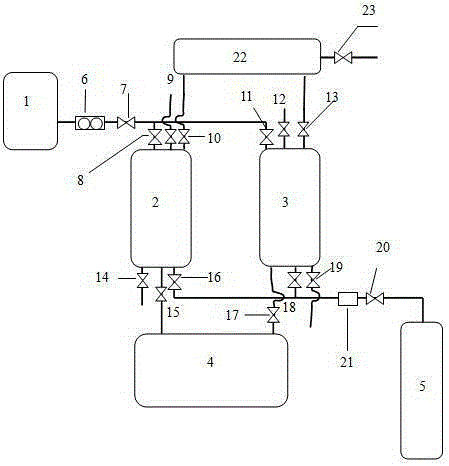

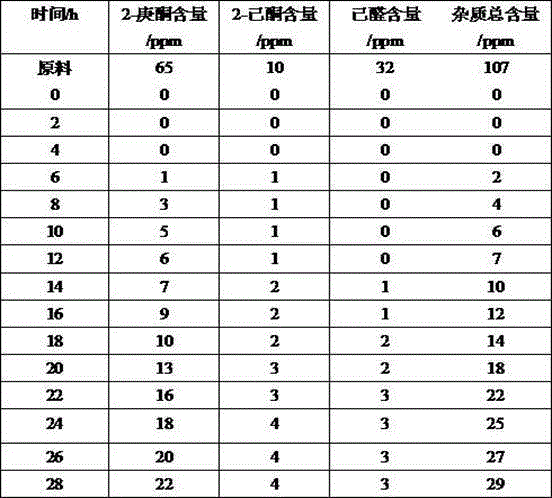

[0023] Weigh 2 parts of 80g MCM-41 bar-shaped molecular sieve, put them in adsorber 1 and adsorber 2 respectively, the temperature of cyclohexanone is 25°C, check all valves to make them in the closed state, and open the inlet and outlet valves 7 and 7 of adsorber 1. 8, 15, control the flow rate of the flowmeter to 5mL / min, and take the cyclohexanone flowing out from the adsorber 1 as 0h, and analyze the sample at the outlet of the adsorber 1. The analysis data is as follows:

[0024]

[0025] When 5h, the total impurity content is 30ppm, and the product does not meet the target requirements, close the inlet and outlet valves 8 and 15 of the adsorber 1, open the inlet and outlet valves 11 and 17 of the adsorber 2, and use the adsorber 2 to adsorb cyclohexanone . At the same time, the molecular sieve in the adsorber 1 is desorbed, the main intake valve 20 is opened, and the gas heater turns the N 2 Heating to 300°C, opening the valves 16 and 10 in turn, desorbing the adsor...

Embodiment 2

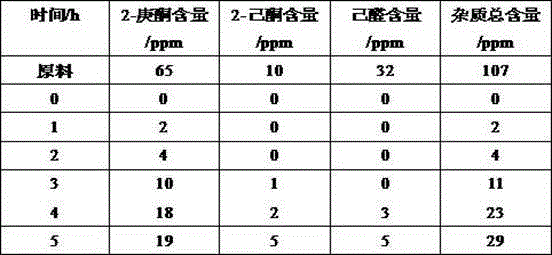

[0030] After the adsorbent in Example 1 is continuously adsorbed and desorbed 10 times, under the same conditions, continue to adsorb, the temperature of cyclohexanone is 25 ° C, check all valves to make it in a closed state, open the inlet and outlet valves 7, 8, 15, control the flow rate of the flowmeter to 5mL / min, and take the cyclohexanone flowing out from the adsorber 1 as 0h, and analyze the sample at the outlet of the adsorber 1. The analysis data is as follows:

[0031]

[0032] When 5h, the total impurity content is 30ppm, and the product does not meet the target requirements, close the inlet and outlet valves 8 and 15 of the adsorber 1, open the inlet and outlet valves 11 and 17 of the adsorber 2, and use the adsorber 2 to adsorb cyclohexanone , the effect is the same as that of the adsorber 1, and the total impurity content after adsorption is less than 30ppm. At the same time, the molecular sieve in the adsorber 1 is desorbed, the main intake valve 20 is opene...

Embodiment 3

[0034] Weigh 50g of ZSM-5 bar-shaped molecular sieve with a silicon-aluminum ratio of 100, and place them in two adsorbers respectively. The temperature of cyclohexanone is 30°C. Check all valves to keep them closed, and open the inlet and outlet of adsorber 1. Valves 7, 8, and 15 control the flow rate of the flowmeter to 5mL / min, and take cyclohexanone to flow out from the adsorber 1 as 0h, and analyze the sample at the outlet of the adsorber 1. The analysis data is as follows:

[0035]

[0036] When 5h, the total impurity content is 29ppm, close to 30ppm, and the product does not meet the target requirements. Close the inlet and outlet valves 8 and 15 of the adsorber 1, open the inlet and outlet valves 11 and 17 of the adsorber 2, and use the adsorber 2 to treat cyclohexanone Adsorption treatment is carried out, and the total content of impurities in the output is less than 30ppm. At the same time, the molecular sieve in the adsorber 1 is desorbed, the main intake valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com