Pneumatic hoist

A hoist and pneumatic technology, which is applied in hoisting devices, clockwork mechanisms, etc., can solve problems such as cumbersome operation and inconvenient use, and achieve the effects of simple operation, ensuring work stability, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

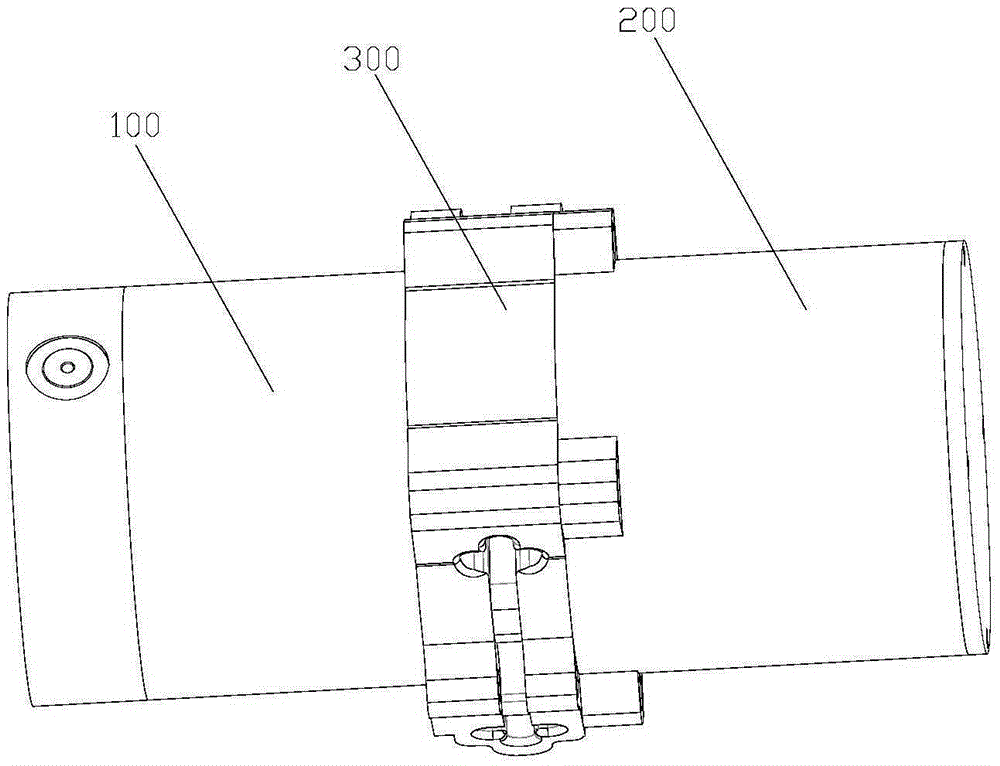

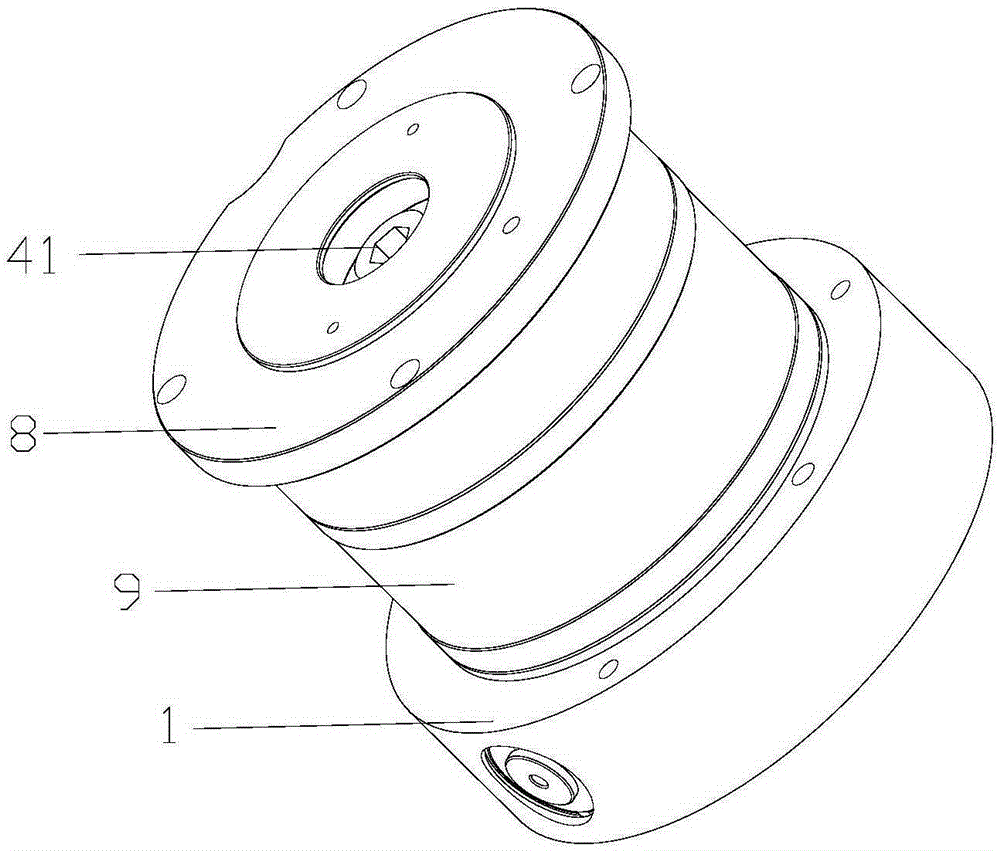

[0038] Such as figure 1 As shown, a pneumatic hoist includes a pneumatic part 100, a transmission part 200 and a lifting part 300; as figure 2 As shown, the pneumatic part 100 includes a vane air motor, a control valve and a braking mechanism.

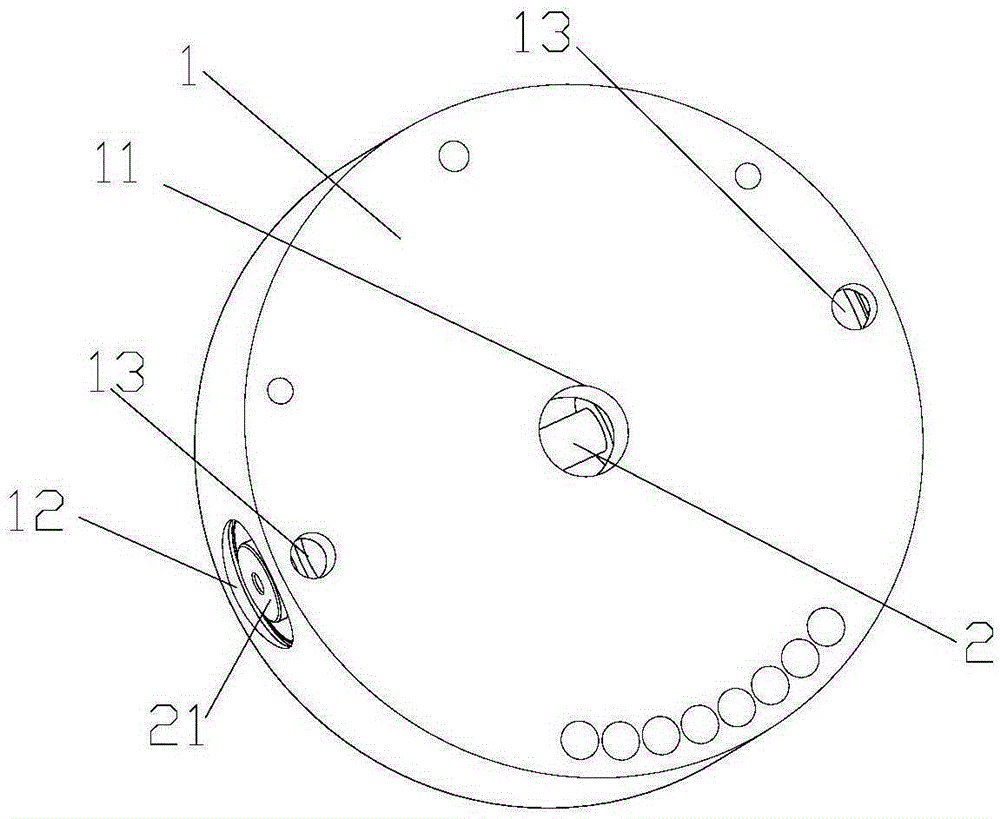

[0039] The control valve includes a valve sleeve 3, such as Image 6 As shown, the valve sleeve 3 is provided with a first air inlet hole 31 and a first air outlet hole 32 and a second air outlet hole 33 respectively located on both sides of the first air inlet hole 31 .

[0040] Such as Figure 5 with 7As shown, the spool 2, the spool 2 includes two annular protrusions 22 matched with the valve sleeve 3, a first air groove 23 is formed between the two annular protrusions 22, The width of the first air groove 23 is smaller than the distance between the first air outlet 32 and the second air outlet 33; the two ends of the valve core 2 are provided with a piston 24; one end of the piston 24 is provided with a second A spring seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com