Novel flour mill for wheat flour milling

A milling machine and flour milling technology, applied in grain processing, etc., can solve the problems of low yield of wheat milling flour and poor screening effect of wheat flour, etc., and achieve easy control, improved milling efficiency, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

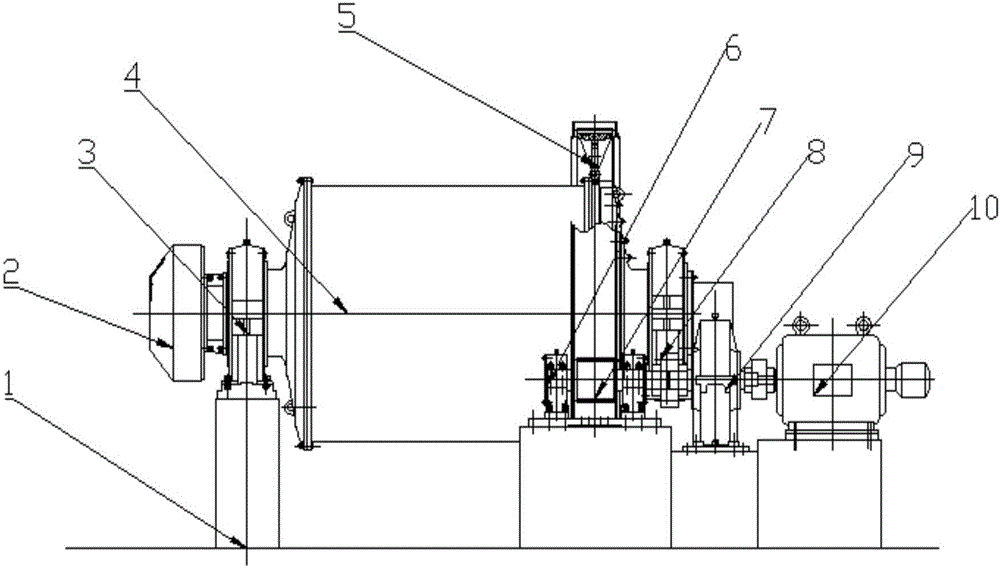

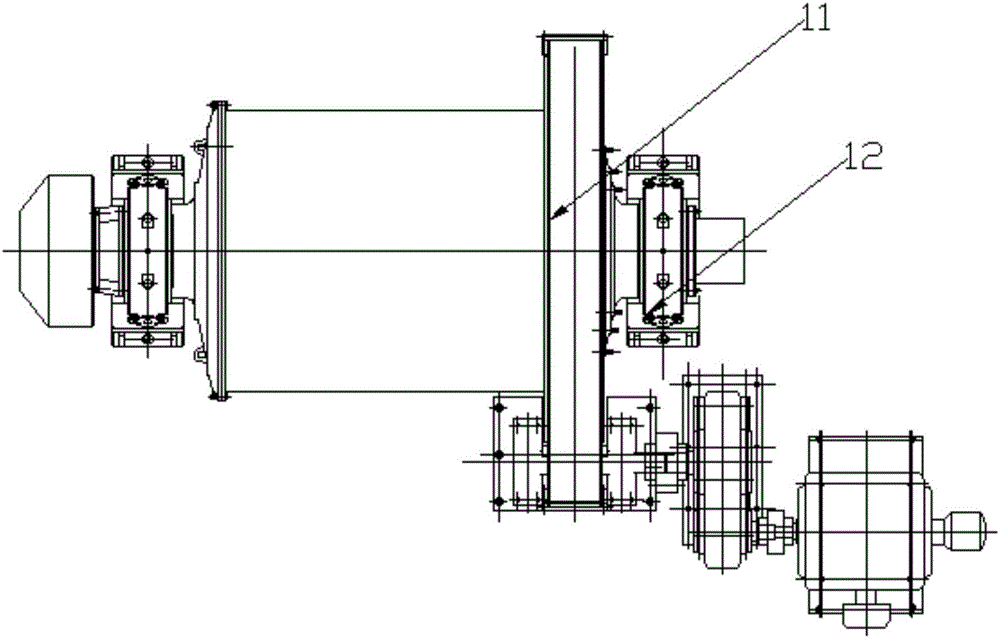

[0016] Such as Figure 1-Figure 2 As shown, a new type of flour mill for wheat flour, including a base 1, a vibrating screen 3, a dust collector 7 and a motor 10, the base 1 can firmly support the entire device, and an outlet 2 is installed on the outer side of its upper end , can overflow and grind the flour, the inner side of the surface outlet 2 is connected with the vibrating sieve 3, which can sieve the flour, the inner side of the vibrating sieve 3 is connected with the drum 4, and the upper end of the drum 4 is installed with the feeding port 5 , wheat can be added, and a drier 6 is installed at the lower end of the feed inlet 5, which can dry wheat and flour. One end of the drier 6 is connected with the dust collector 7, which can remove the overflowing flour. The outer side of the 7 is communicated with an agitator 8, which can be used for flour grinding and stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com