Milking sow concentrated feed applicable to wet-mixing feeding and preparation method thereof

A technology of concentrated feed for lactating sows, applied in the field of concentrated feed for lactating sows, can solve the problems of unconsidered taste changes and nutrient release, palatability decline, feed disconnection, etc. Strong flavor and palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

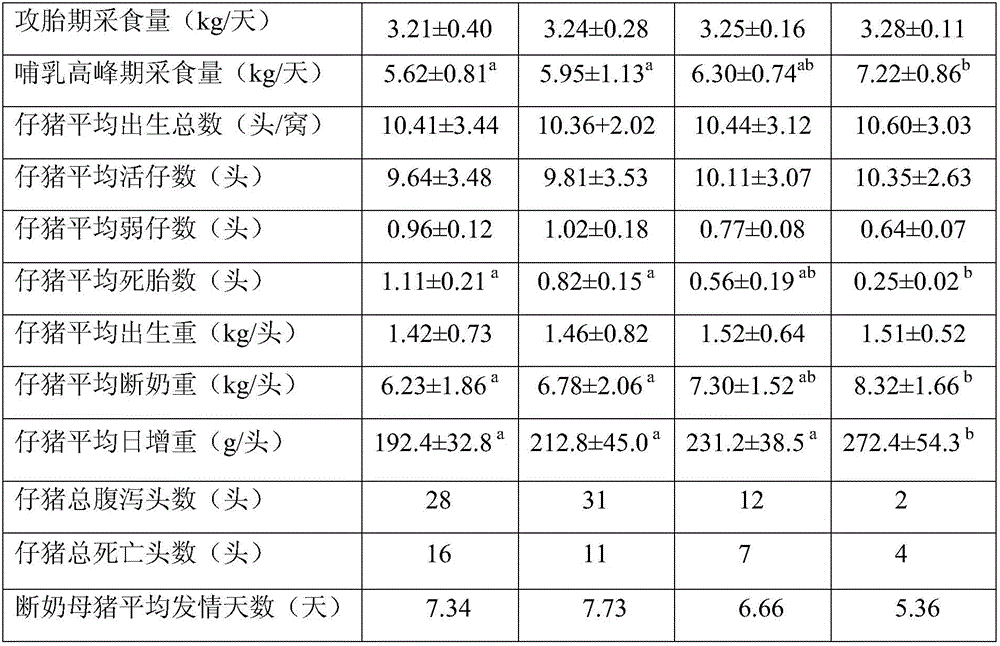

Examples

Embodiment 1

[0031] A concentrated feed for lactating sows suitable for wet-mix feeding can be prepared by the following methods:

[0032] 1)Accurately weigh 110kg of puffed corn, 110kg of puffed soybean meal, 190kg of ordinary soybean meal, 50kg of citric acid vinasse, 100kg of imported steam fish meal, 68kg of soybean oil, 63kg of lard residue, 33kg of stone powder, 54kg of calcium hydrogen phosphate, 67kg of brown sugar, 30kg of salt, 55kg of yeast hydrolysate, 35kg of compound beneficial active bacteria agent, 15kg of compound organic acidifier, and 20kg of premix.

[0033] First, accurately weigh the lard residue and brown sugar according to the formula, then move it into the conditioner, add saturated steam, control the tempering temperature at 95℃, and the preparation time for 180 seconds, and then unload the tempered and matured materials in Cool to below 40℃ in the cooler;

[0034] 2) Accurately weigh the remaining raw materials according to the formula ratio. The expanded corn and soyb...

Embodiment 2

[0040] A concentrated feed for lactating sows suitable for wet-mix feeding, prepared by the following method:

[0041] 1)Accurately weigh 120kg of puffed corn, 100kg of puffed soybean meal, 180kg of ordinary soybean meal, 60kg of citric acid grain protein, 90kg of imported steam fish meal, 65kg of soybean oil, 60kg of lard residue, 30kg of stone powder, 64kg of calcium hydrogen phosphate, 76kg of brown sugar, 25kg of salt, 60kg of yeast hydrolysate, 35kg of compound beneficial active bacteria, 15kg of compound organic acidifier, and 20kg of premix.

[0042] First, accurately weigh the lard residue and brown sugar according to the formula, then move it into the conditioner, add saturated steam, control the tempering temperature at 90℃, and the preparation time for 240 seconds, and then unload the tempered and matured materials in Cool to below 40℃ in the cooler;

[0043] 2) Accurately weigh the remaining raw materials according to the formula ratio. The expanded corn and soybean meal...

Embodiment 3

[0049] A concentrated feed for lactating sows suitable for wet-mix feeding, prepared by the following method:

[0050] 1)Accurately weigh 115kg of puffed corn, 100kg of puffed soybean meal, 180kg of ordinary soybean meal, 52kg of citric acid grains, 100kg of imported steam fish meal, 75kg of soybean oil, 57kg of lard residue, 32kg of stone powder, 63kg of calcium hydrogen phosphate, 68kg of brown sugar, 33kg of salt, 55kg of yeast hydrolysate, 35kg of compound beneficial active bacteria, 15kg of compound organic acidifier, and 20kg of premix;

[0051] First accurately weigh the lard residue and brown sugar according to the formula, then move it into the conditioner, add saturated steam, control the tempering temperature at 93°C, and the preparation time for 200 seconds, and then unload the tempered and matured materials into Cool to below 40℃ in the cooler;

[0052] 2) Accurately weigh the remaining raw materials according to the formula ratio. The expanded corn and soybean meal are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com