Rapid scale removing and fish killing machine

A fast, chassis-based technology, used in fish processing, fish cleaning/descaling, slaughtering, etc., can solve the problems of unfavorable operator health, low work efficiency, low labor intensity, etc., and achieve fast and clean fish scales and use effects. Stable, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment, present embodiment is based on the premise of the technical scheme of the present invention, has provided detailed implementation and specific operation process, but protection scope of the present invention is not limited to following implementation example.

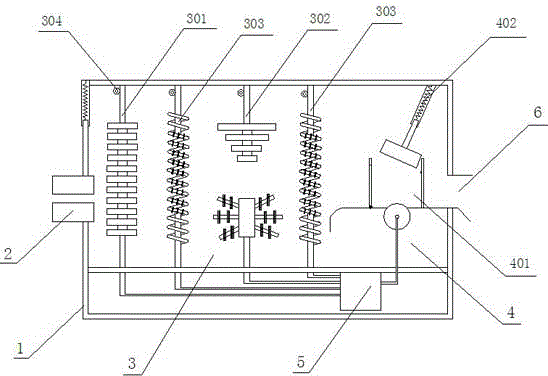

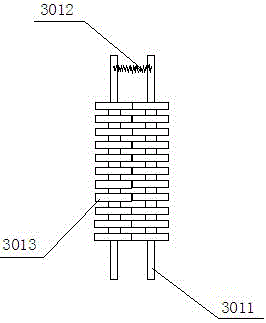

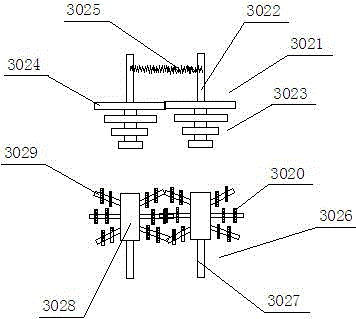

[0024]As shown in the figure, a fast descaling fish killing machine according to the present invention includes a chassis 1, on which a fish inlet 2 and a fish outlet 6 are arranged, and the fish inlet 2 will enter the chassis 1 through it The fish is vertically fixed, and the cabinet 1 is provided with a descaling device 3 for scraping fish scales and an opening device 4 for breaking open the belly of the fish. The descaling device 3 and the opening device 4 are driven by a motor 5 to move, and the descaling device 3 It includes a side body descaling mechanism 301 for removing fish side body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com