Steering rack performance test bed

A test bed and bogie technology, applied in the field of rail vehicle bogie test bed, can solve the problems of large space occupation, single function, poor compatibility, etc., and achieve the effect of small space occupation, strong safety and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

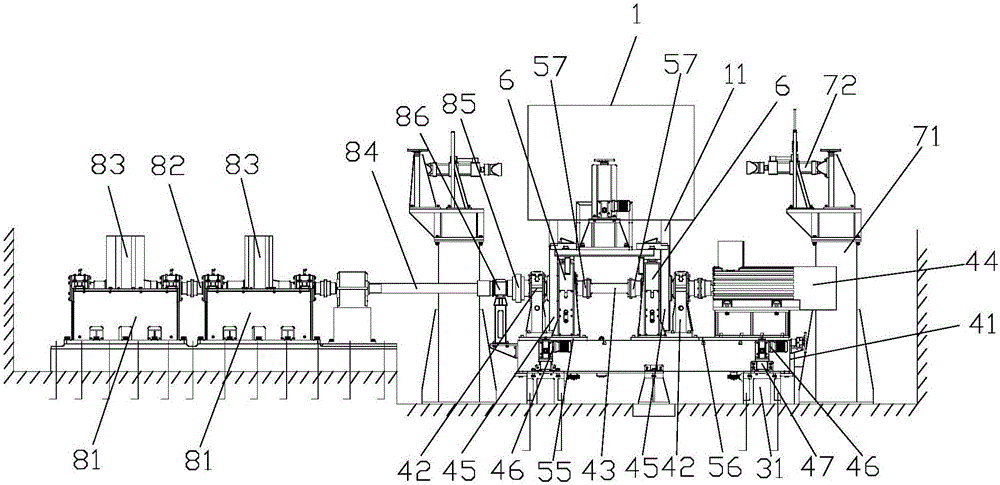

[0032] Such as Figures 1 to 5 As shown, the bogie performance test bench includes a track device capable of carrying a test vehicle 1 and a traction device 2 located at the front side of the track device.

[0033] The towing device 2 includes a fixed seat 21 fixed on the foundation 3 and a tow bar 22 capable of connecting and towing the test vehicle 1 . The tow bar 22 is connected to the fixed seat 21 .

[0034] The track device includes a plurality of track wheel units 4 arranged from front to back.

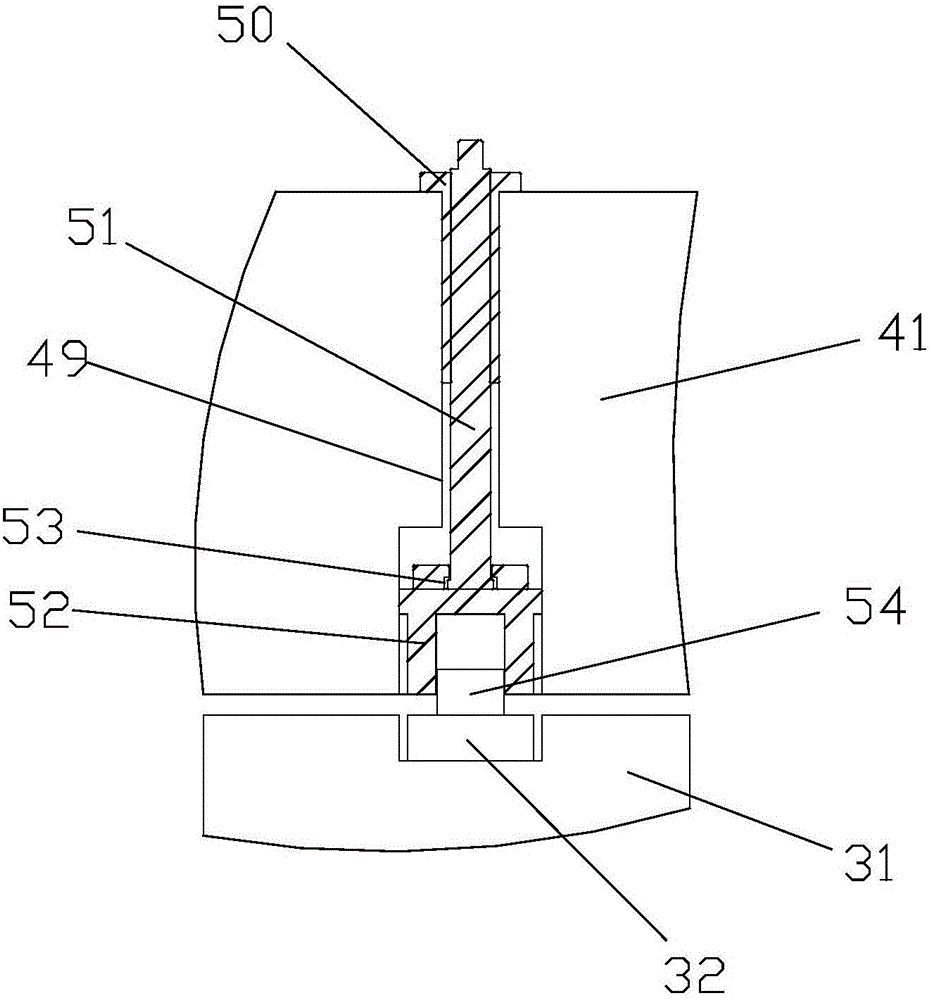

[0035] The track wheel unit 4 comprises a mounting platform 41, two support bases 42 installed on the left and right sides of the mounting platform 41, a track wheel shaft 57 installed on the support base 42, and a traction motor installed on the mounting platform 41 for driving the track wheel shaft 57 44.

[0036] The track wheel axle 57 is installed on the supporting seat 42 through the bearing, and the track wheel 45 for carrying the wheel 11 of the test vehicle 1 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com