A robot power station inspection system and method

A technology of robots and inspection robots, applied in control/regulation systems, instruments, non-electric variable control, etc., can solve the problems of dangerous inspection personnel, complex environment, and heavy workload, and achieve accuracy and consistency. Promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

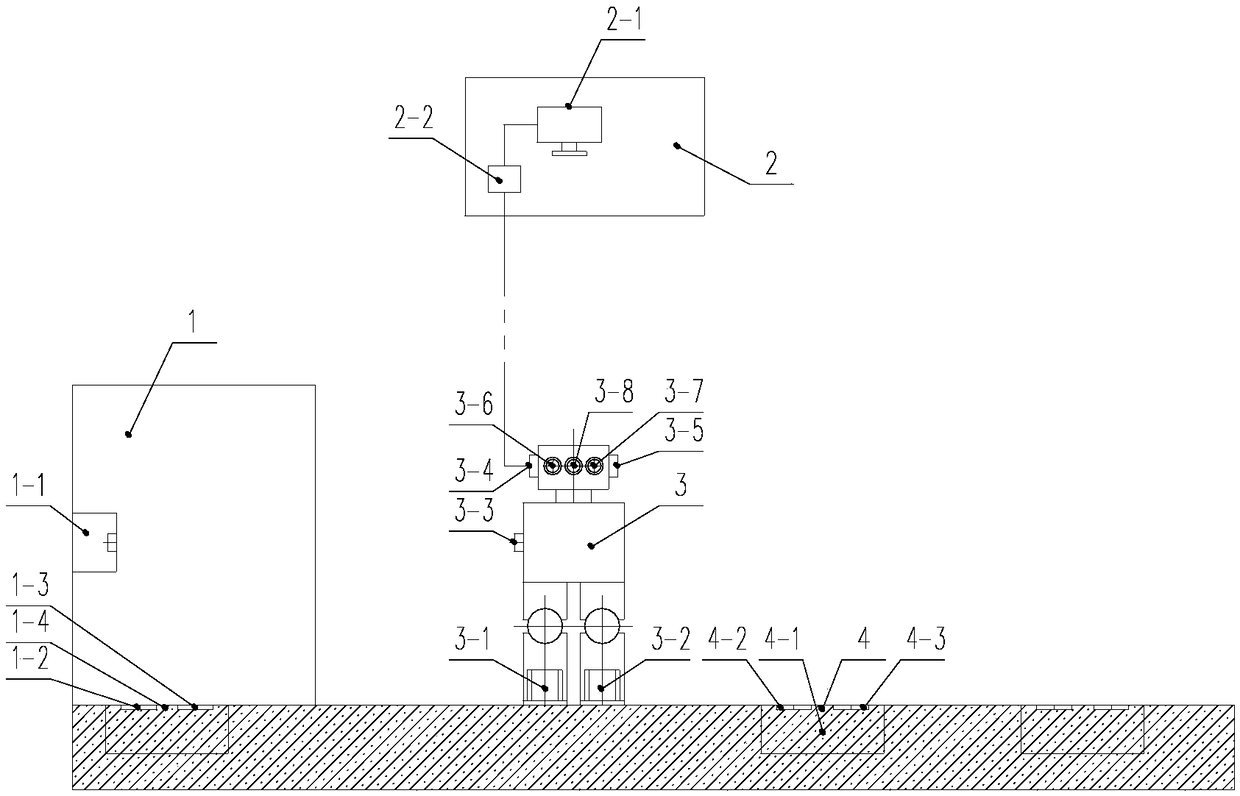

[0020] Such as figure 1 As shown, a robot power station inspection system includes a robot base station 1, a main control room 2, an inspection robot 3, and an inspection point 4; the robot base station 1 is provided with a base station charging stand 1-1 and a base station charging positioning point 1-4, the base station charging anchor point 1-4 includes the base station charging left anchor point 1-2 and the base station charging right anchor point 1-3, the surface shape of the base station charging left anchor point 1-2 and the inspection robot 3 The surface shape of the bottom surface of the left foot is the same, and the surface shape of the right anchor point 1-3 of the base station charging is the same as the surface shape of the right foot surface of the inspection robot 3; the main control room 2 is provided with a main control computer 2-1 and Main control room signal remote switcher 2-2; the left foot of the inspection robot 3 is provided with a robot left foot ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com