Automatic powder feeding device and washing machine

An automatic feeding and powder technology, which is applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of poor accuracy and achieve the effect of automatic feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

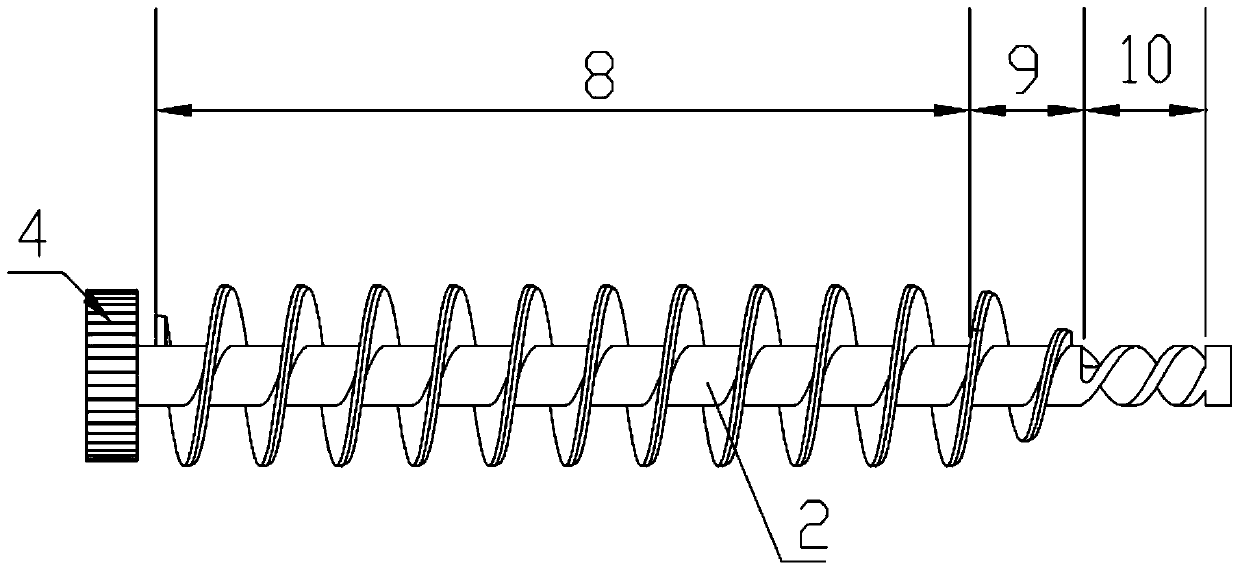

[0023] Such as figure 1 , 2 As shown, an automatic powder dispensing device of the present invention is used to dispense powder materials such as powder flocculant or washing powder. It includes a housing 1 and a screw 2. The screw 2 is rotatably installed at the bottom of the inner cavity of the housing and connected to a driving device. 2 is a variable diameter screw, divided into large diameter section, transition section and small diameter section. The diameter of the large diameter section of the screw is the same, and the diameter of the small diameter section of the screw is the same. There is a transition section between the large diameter section and the small diameter section of the screw. The thread diameter of the section gradually changes from large to small, and it is continuous with the thread of the large diameter section; the large diameter section and transition section of the screw are of single helix structure, and the small diameter section of the screw is of...

Embodiment 2

[0038] The washing machine described in this embodiment is equipped with the automatic powder dispensing device described in the first embodiment, which is used to accurately put powder materials such as powder flocculant or washing powder on the washing machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com