A method for preparing high-performance iron-rich recycled aluminum with trace compound additives

A composite additive and recycled aluminum technology, which is applied in the field of recycled aluminum material preparation, can solve the problems of lower mechanical properties of cast aluminum-silicon alloys, achieve the effects of easy control of components, simple process and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

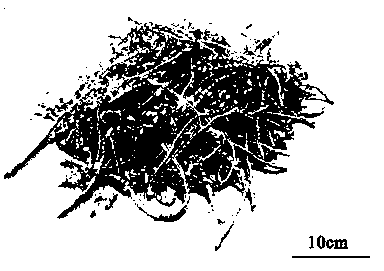

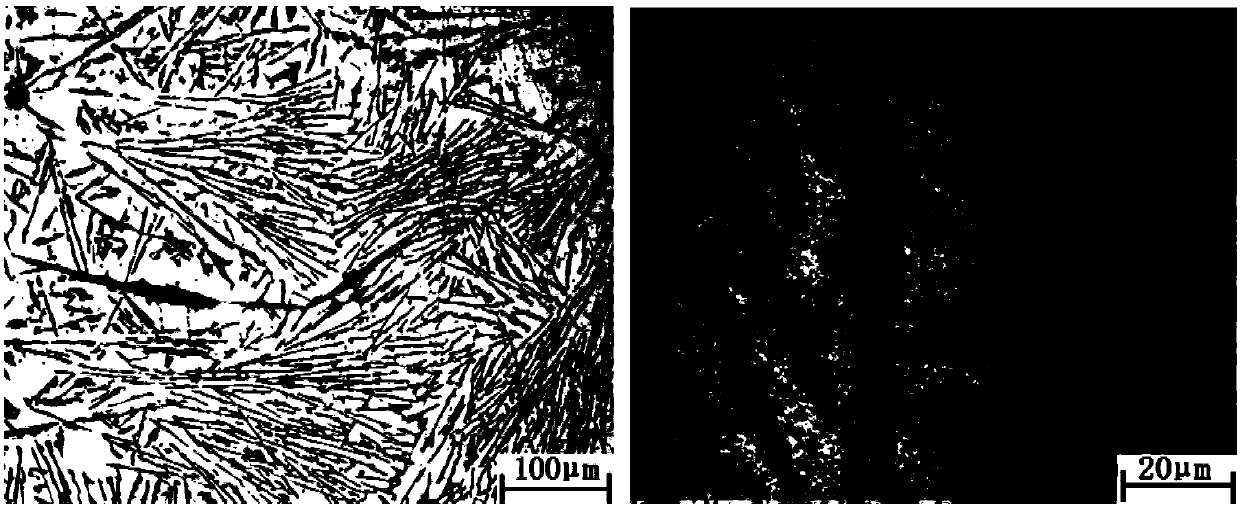

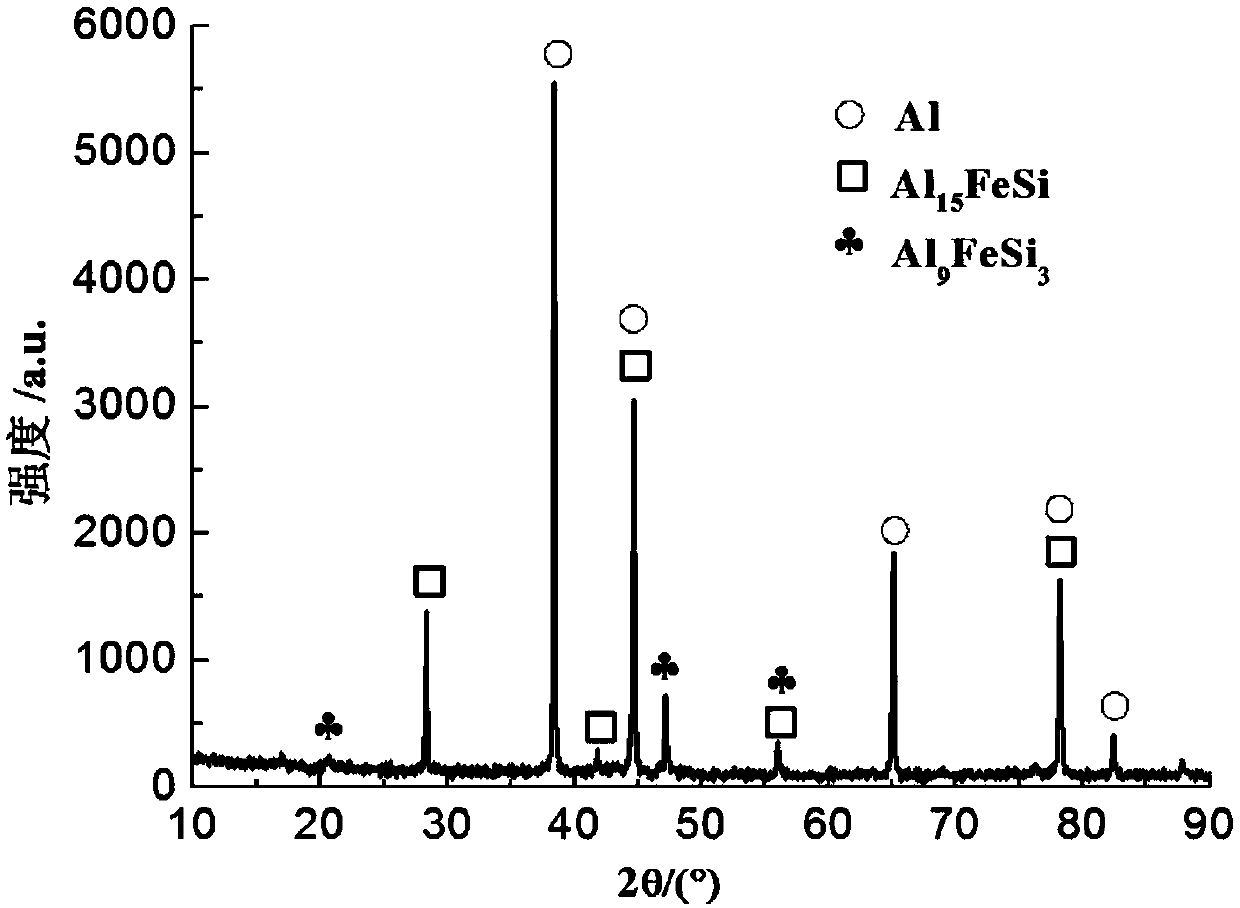

Image

Examples

Embodiment 1

[0026] The method for preparing high-performance iron-rich recycled aluminum with a small amount of compound additives, the operation steps are as follows:

[0027] The method uses equipment and tools: the heating equipment is a crucible resistance furnace, an oven, the machining equipment is a lathe, a mechanical grinder, and other tools include a slag removal tool, a bell jar, a stirring tool and a metal mold.

[0028] The composition of the iron-rich recycled aluminum to be processed by the method is Si: 10.5%, Cu: 1.5%, Fe: 1.3%, and the balance is aluminum. The refining agent used is C 2 Cl 6 .

[0029] 1. Preparation of trace compound additives

[0030] Weighing by weight percentage, Al-5Ti-0.5C: 5%, Al-10Mn: 55%, Al-10Sr: 25%, Al-10Ce: 15% are mixed uniformly to prepare a trace compound additive for future use.

[0031] 2. Put the iron-rich recycled aluminum alloy chips to be processed into a graphite crucible, heat it to 750°C in a crucible resistance furnace to me...

Embodiment 2

[0034] The method for preparing high-performance iron-rich recycled aluminum with a small amount of compound additives, the operation steps are as follows:

[0035] The equipment and tool used in this method: with embodiment 1.

[0036] The components of the iron-rich recycled aluminum to be processed by the method are Si: 12.0%, Cu: 3.0%, Fe: 2.0%, and the balance is aluminum. The refining agent used is C 2 Cl 6 .

[0037] 1. Preparation of trace composite additives; weighed by weight percentage, Al-5Ti-0.5C: 13%, Al-10Mn: 52%, Al-10Sr: 22%, Al-10Ce: 13%, mixed evenly to prepare a trace composite additive spare.

[0038] 2. Put the iron-rich recycled aluminum alloy chips to be processed into the graphite crucible, heat it in the crucible resistance furnace to 753°C and melt it into a melt. After it is completely melted, add refining agent C after keeping it warm for 10 minutes 2 Cl 6 Refining is carried out, and the surface scum is removed after refining. Obtain recycl...

Embodiment 3

[0041] The method for preparing high-performance iron-rich recycled aluminum with a small amount of compound additives, the operation steps are as follows:

[0042] The equipment and tool used in this method: with embodiment 1.

[0043]The composition of the iron-rich recycled aluminum to be processed by the method is Si: 11.0%, Cu: 2.5%, Fe: 1.8%, and the balance is aluminum. The refining agent used is C 2 Cl 6 .

[0044] 1. Prepare trace composite additives; by weight percentage, Al-5Ti-0.5C: 27%, Al-10Mn: 55%, Al-10Sr: 9%, Al-10Ce: 9%, mix uniformly to prepare trace composite additives for later use.

[0045] 2. Put the iron-rich recycled aluminum alloy chips to be processed into a graphite crucible, heat it to 750°C in a crucible resistance furnace to melt into a melt, and add refining agent C after it is completely melted and kept warm for 20 minutes 2 Cl 6 Refining is carried out, and the surface scum is removed after refining. Obtain recycled aluminum melt.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com