Anti-oil pollution anti-X-ray radiation plexiglass masterbatch and method for preparing plexiglass

A technology of plexiglass and light radiation, applied in the field of plexiglass, which can solve the problems of plexiglass not being oil-proof, labor-intensive and material-resource-intensive, and difficult to clean, and achieve improved X-ray radiation resistance, small intermolecular forces, and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: a kind of anti-oil stain and anti-X-ray radiation plexiglass master batch adopts the following components:

[0026] 60 parts by mass of methyl methacrylate, 20 parts by mass of lead methacrylate, 9.95 parts by mass of lead octoate, 0.05 parts by mass of an initiator, and 10 parts by mass of fluoroacrylate.

[0027] In the present embodiment, the anti-oil stain anti-X-ray radiation plexiglass masterbatch is made into plexiglass according to the following preparation method:

[0028] S1, first add the anti-oil stain and anti-X-ray plexiglass masterbatch into the reaction kettle, carry out pre-polymerization in an environment of 80°C to generate a pre-polymerized liquid, and carry out the reaction for 60 minutes, and the liquid to be pre-polymerized becomes viscous When thick as glycerin liquid, stop heating and cool to room temperature quickly;

[0029] S2, pour the pre-polymerized liquid into the mold, put it in an oven at 30°C and keep it warm for 5-7 hou...

Embodiment 2

[0035] Embodiment 2: a kind of anti-oil stain and anti-X-ray radiation plexiglass master batch adopts the following components:

[0036] 75 parts by mass of methyl methacrylate, 10 parts by mass of lead methacrylate, 9.95 parts by mass of lead octoate, 0.05 parts by mass of initiator, 5 parts by mass of fluoroacrylate, and 5 parts by mass of other monomers.

[0037] In this example, the masterbatch is weighed according to the above components, and the X-ray-resistant organic glass is prepared according to the preparation method of Example 1.

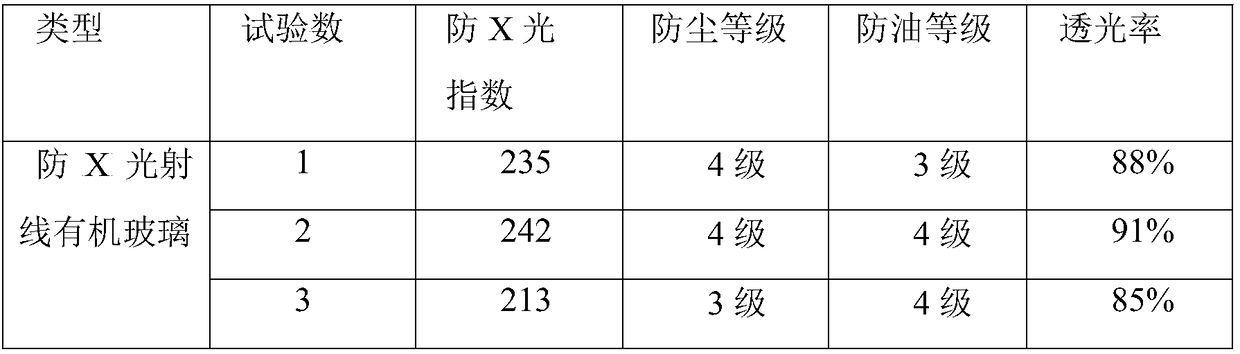

[0038] The anti-X-ray plexiglass and ordinary plexiglass were carried out radiation protection test and oil stain resistance comparison test under the same thickness of 2cm, the results are as follows

[0039]

[0040] As can be seen from the above table, this kind of anti-X ray plexiglass is compared with ordinary plexiglass, and oil stain resistance and X-ray ray resistance have greatly improved, and compared with the anti-X ray ray...

Embodiment 3

[0041] Embodiment 3: a kind of anti-oil stain and anti-X-ray radiation plexiglass master batch adopts the following components:

[0042] 65 parts by mass of methyl methacrylate, 15 parts by mass of lead methacrylate, 9.95 parts by mass of lead octoate, 0.05 parts by mass of initiator, 10 parts by mass of fluoroacrylate, and 10 parts by mass of other monomers.

[0043] In this example, the masterbatch is weighed according to the above components, and the X-ray-resistant organic glass is prepared according to the preparation method of Example 1.

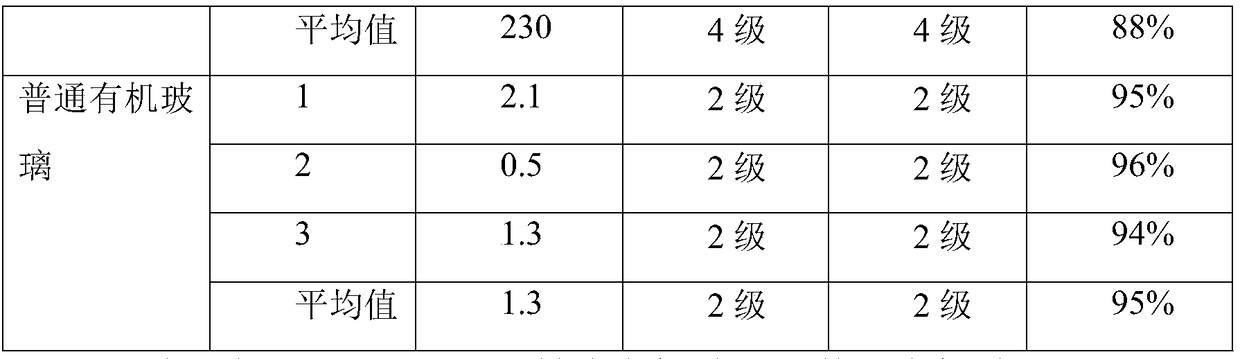

[0044] The anti-X ray plexiglass and common plexiglass were carried out radiation protection test and anti-oil stain comparison test under the same thickness of 2cm, the results are as follows

[0045]

[0046] As can be seen from the above table, the anti-X ray plexiglass is compared with common plexiglass, and the oil resistance and the X ray ability are greatly improved, and compared with the anti X ray plexiglass in Example 1, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com