Continuous preparation method of tricyclopentadiene

A technology of tricyclopentadiene and dicyclopentadiene, which is applied in the field of continuous preparation of tricyclopentadiene, can solve the problems of labor cost, equipment cost and production cost increase, complicated operation, long polymerization time, etc. Polymerization time, high volumetric efficiency, and small back-mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The dicyclopentadiene raw material with a purity of 95wt% is transported and injected from the lower port of the tubular reactor with a high-pressure constant-flow pump at a flow rate of 3ml / s. The reactor volume is 60ml, the aspect ratio is 50, and the reaction volume space velocity is 3h -1 , the heating temperature of the reaction tube is 180°C, and the reaction pressure is 2MPa. After the reaction is stable, the product is collected at the outlet, and there is no loss of material during the entire reaction process. The composition of the product was analyzed by gas chromatography, and the content of dicyclopentadiene in the mixture was 67.6wt%, the mass content of tricyclopentadiene was 31.3wt%, and the content of by-product high polymer was 1.1wt%.

Embodiment 2

[0022] The dicyclopentadiene raw material with a purity of 95wt% is transported and injected from the lower port of the tubular reactor with a high-pressure constant-flow pump at a flow rate of 5ml / s. The reactor volume is 150ml, the aspect ratio is 40, and the reaction volume space velocity is 2h -1 , the heating temperature of the reaction tube is 200°C, and the reaction pressure is 3MPa. After the reaction is stable, the product is collected at the outlet, and there is no loss of material during the entire reaction process. The composition of the product was analyzed by gas chromatography, and the content of dicyclopentadiene in the mixture was 60.3wt%, the mass content of tricyclopentadiene was 36.3wt%, and the content of by-product high polymer was 3.4wt%.

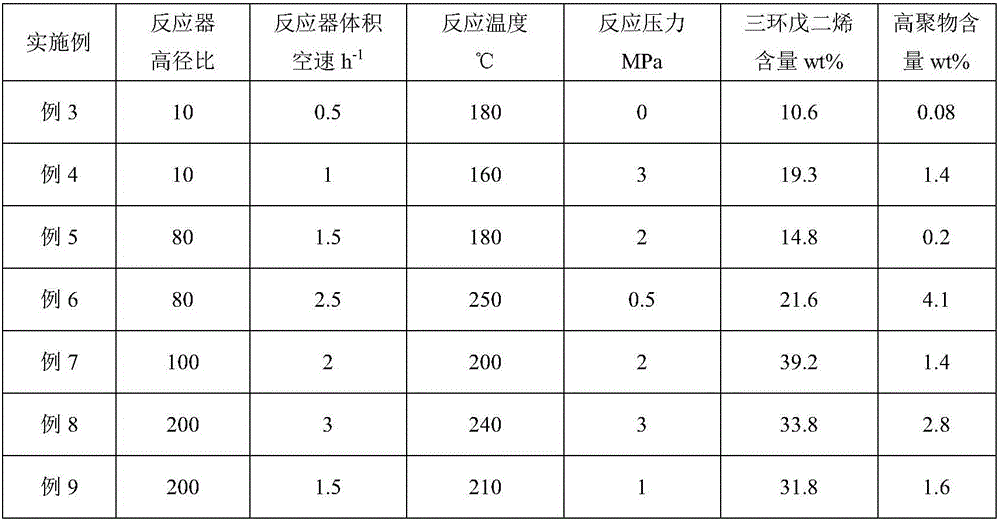

Embodiment 3-9

[0024] The polymerization reaction process of each embodiment is the same as that of Examples 1 and 2, except that the adjustment of reaction conditions includes: reactor aspect ratio, reactor volume space velocity, reaction temperature, and reaction pressure. Finally, mixed products containing tricyclopentadiene with different mass contents were obtained.

[0025]

[0026] Using dicyclopentadiene as raw material and using continuous polymerization in a tubular reactor instead of intermittent polymerization in a reactor to prepare tricyclopentadiene can effectively improve the polymerization efficiency, simplify the reaction process, greatly reduce manual operations, save production costs, and are more conducive to large-scale production.

[0027] The height-to-diameter ratio range of the tubular reactor is selected between 10 and 200. Under the condition of a certain reactor volume, too small a height-to-diameter ratio may cause insufficient heating of the material in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com