A method for treating stagnant slabs in slab continuous casting

A treatment method and continuous slab casting technology, applied in the field of slab continuous casting stagnation treatment, can solve the problems of ineffective drawing, increased drawing resistance, failure of driving rollers, etc., saving time, reducing Pulling resistance, ensure the effect of pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

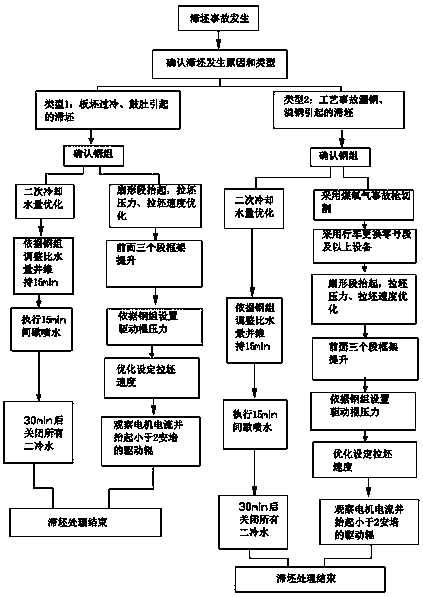

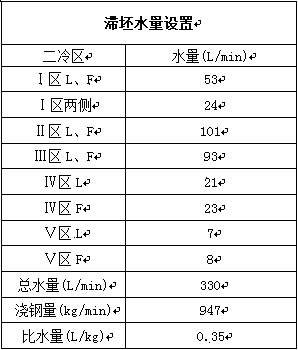

[0034] A method for processing stagnant slab continuous casting, the method is implemented according to the following steps:

[0035] First of all, determine the type and cause of the slab stagnation. According to the current situation of the slab continuous casting machine at home and abroad, it can be roughly divided into two categories: (1) continuous casting caused by equipment failure and operation reasons Long downtime of the machine, stagnation caused by overcooling of the slab or stagnation caused by the local thickness of the slab exceeding the set value caused by the failure of the process, continuous casting cooling, and hydraulic equipment; (2) abnormal process accidents of the continuous casting machine , such as steel breakout and steel overflow, which cause the slab and other equipment of the casting machine to have cold steel jamming or stagnation caused by bonding;

[0036] 1. Long shutdown time of continuous casting machine caused by equipment failure and ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com