Functional composition capable of increasing bone density and applications thereof

A technology for increasing bone density and functionality, applied in the application field of preparing dairy products, can solve the problems of large addition amount and bitter taste in the product, and achieve the effect of increasing bone density and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

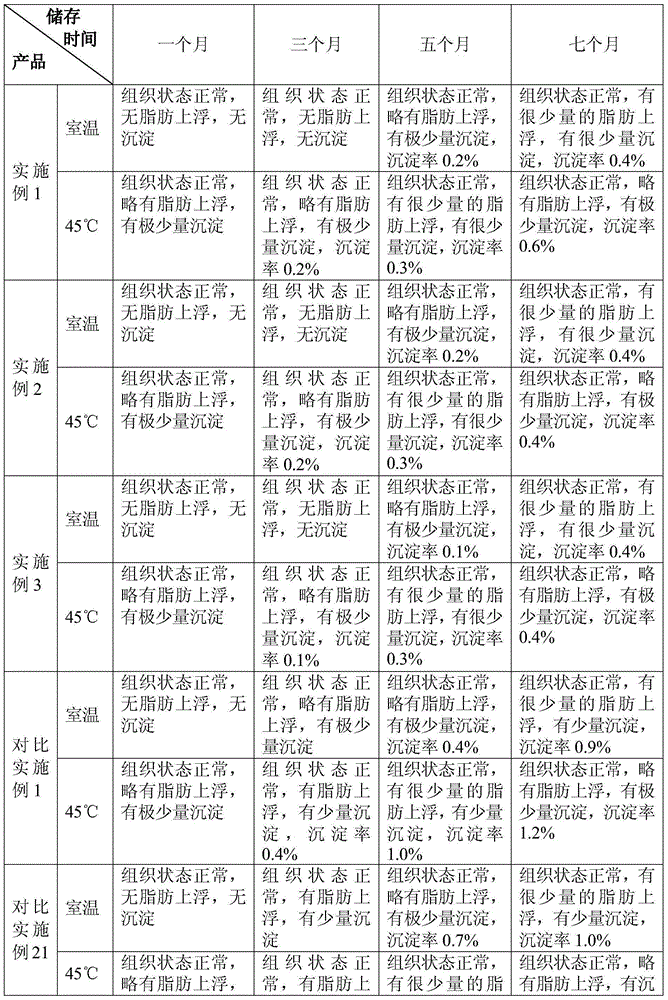

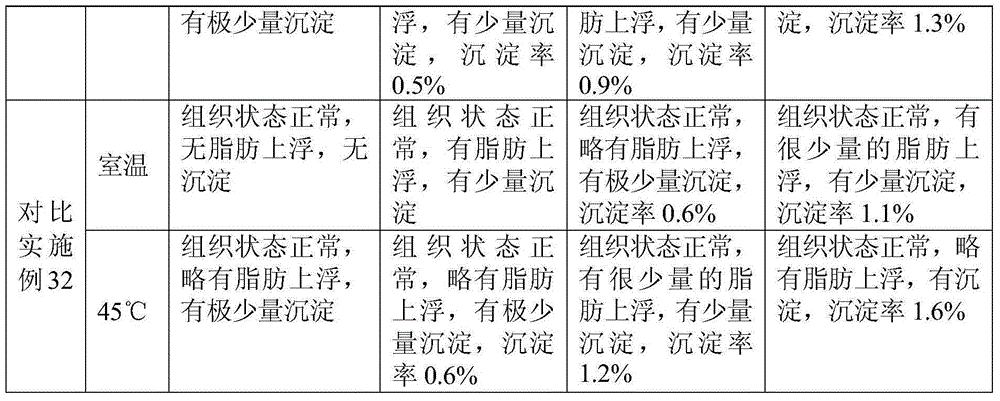

Examples

Embodiment 1

[0026] A liquid dairy product with increased bone density is prepared, which has the following composition:

[0027] Milk 70.0 parts; stabilizer (carrageenan: 0.01 part; gellan gum: 0.02 part; microcrystalline cellulose 0.01 part) 0.04 part; functional composition (milk calcium: 0.5 part; casein phosphopeptide: 1.0 part; three Sodium polyphosphate: 0.1 parts): 1.6 parts; ingredient water: 28.36 parts. Wherein, the content of calcium element in milk calcium is 23%, and the purity of casein phosphopeptide is 15%.

[0028] Preparation method of the present invention, its steps are as follows:

[0029] (1) The raw milk whose temperature does not exceed 8°C is used to remove mechanical impurities in the raw milk through a milk cleaning process;

[0030] (2) Pasteurize the cleaned raw milk at 75°C for 30 seconds, and cool the pasteurized milk to below 8°C;

[0031] (3) Ingredients: heat part of the pasteurized milk to 70°C, then add the stabilizer and functional composition, and ...

Embodiment 2

[0035] Milk 80.0 parts; stabilizer (carrageenan: 0.03 parts; gellan gum: 0.02 parts; microcrystalline cellulose 0.03 parts) 0.08 parts; functional composition (calcium lactate: 0.3 parts; casein phosphopeptide: 1.5 parts; coke Sodium phosphate: 0.20 parts): 2.0 parts; ingredient water: 17.92 parts. Wherein, the content of calcium element in calcium lactate is 98%, and the purity of casein phosphopeptide is 15%.

[0036] Preparation method of the present invention, its steps are as follows:

[0037] (1) The raw milk whose temperature does not exceed 8°C is used to remove mechanical impurities in the raw milk through a milk cleaning process;

[0038] (2) Pasteurize the cleaned raw milk at 85°C for 15 seconds, and cool the pasteurized milk to below 8°C;

[0039] (3) Ingredients; heat part of the pasteurized milk to 75°C, then add the stabilizer and functional composition, and mix the ingredients under stirring conditions, and the mixing time is 25 minutes;

[0040] (4) Add the...

Embodiment 3

[0043] Milk 85.0 parts; stabilizer (carrageenan: 0.05 parts; gellan gum: 0.05 parts; microcrystalline cellulose 0.10 parts) 0.20 parts; functional composition (milk calcium: 2.8 parts; casein phosphopeptide: 2.0 parts; three Sodium polyphosphate: 0.5 parts): 5.3 parts; ingredient water: 9.50 parts. Wherein, the content of calcium element in milk calcium is 23%, and the purity of casein phosphopeptide is 15%.

[0044] Preparation method of the present invention, its steps are as follows:

[0045] (1) The raw milk whose temperature does not exceed 8°C is used to remove mechanical impurities in the raw milk through a milk cleaning process;

[0046] (2) Pasteurize the cleaned raw milk at 90°C for 10 seconds, and cool the pasteurized milk to below 8°C;

[0047] (3) Ingredients: heat part of the pasteurized milk to 80°C, then add the stabilizer and functional composition, and mix the ingredients under stirring conditions for 20 minutes;

[0048] (4) Add the remaining pasteurized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com