A kind of anti-drop structure and its production process

A drop-proof, glass cover technology, applied in the fields of instruments, computing, electrical digital data processing, etc., can solve the problems of easily broken TP glass cover, TP glass cover without a drop-proof structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The anti-drop structure of the present invention can be applied to all terminals with touch screens, such as tablet computers, mobile phones, etc. The anti-drop structure of the present invention can protect the TP glass cover plates of these terminals, reducing the risk of falling easily when the terminal accidentally falls Chance of breaking TP glass cover.

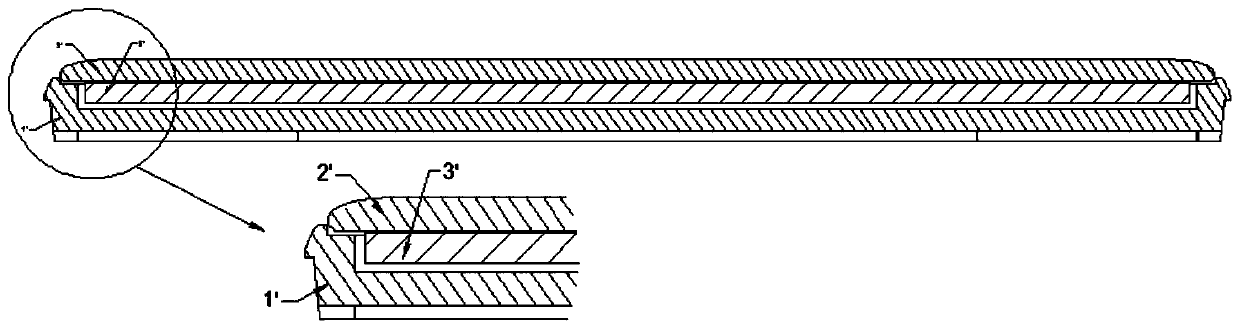

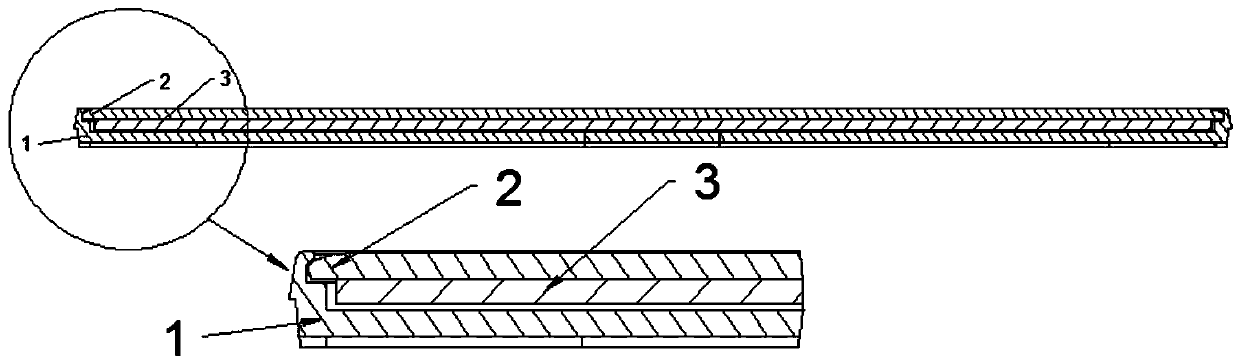

[0032] The terminal in this embodiment takes a smart phone as an example, that is, what this embodiment provides is an anti-drop structure that matches the touch screen of the smart phone, such as figure 2 As shown, it includes a cover 1, a TP glass cover 2 and an LCD display module 3, wherein the cover 1 carries the LCD display module 3 and has an inverted edge, and the TP glass cover 2 is attached to the LCD display module 3 surface, and the undercut edge of the face shell is snapped onto the edge of the TP glass cover plate 2. There is a full circle of undercut structure on the face shell, which is used to w...

Embodiment 2

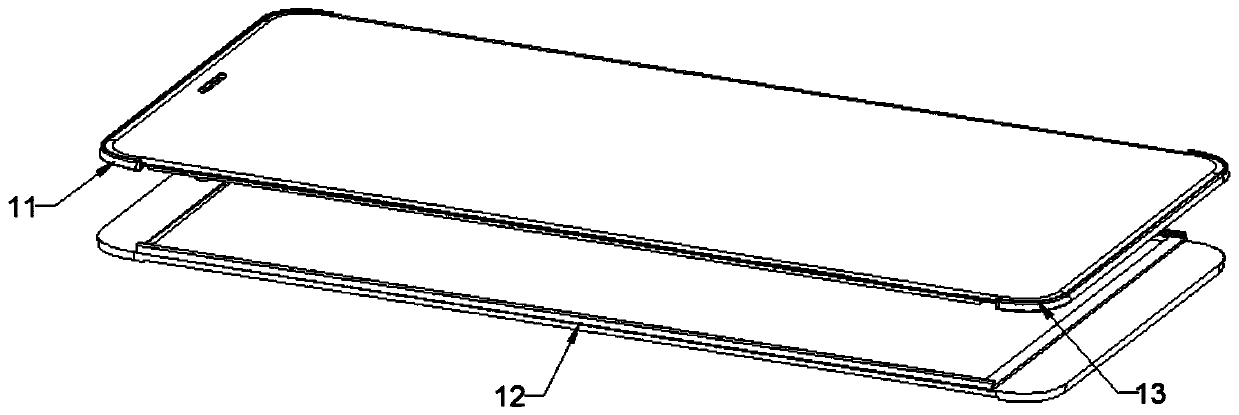

[0041] A production process for an anti-fall structure, used to assemble the above-mentioned anti-fall structure, such as Figure 4 shown, including the following steps:

[0042] Step 1, assembling the LCD display module into the frame body of the panel;

[0043] Step 2, glue the upper part and lower part of the face shell with pre-dotted glue or attached foam glue to the two ends of the TP glass cover respectively;

[0044] Step 3: Attach the TP glass cover plate glued to the upper and lower ends of the face shell on the LCD display module installed in the frame-shaped body of the face shell, and place the upper and lower ends of the face shell without the undercut edge A group of opposite sides that have no undercut edges with the frame-shaped body are respectively connected by bonding to form an integral surface shell structure.

[0045] In this embodiment, at first the LCD display module 3 is packed into the frame body 2 of the face shell, and then the upper end part 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com