Toner cartridge and an image forming device

A toner cartridge and toner technology are applied in the fields of image forming devices and toner cartridges, and can solve problems such as easy breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

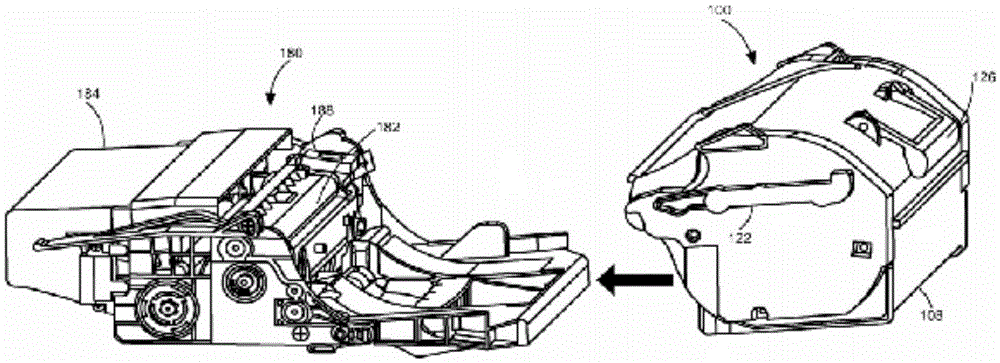

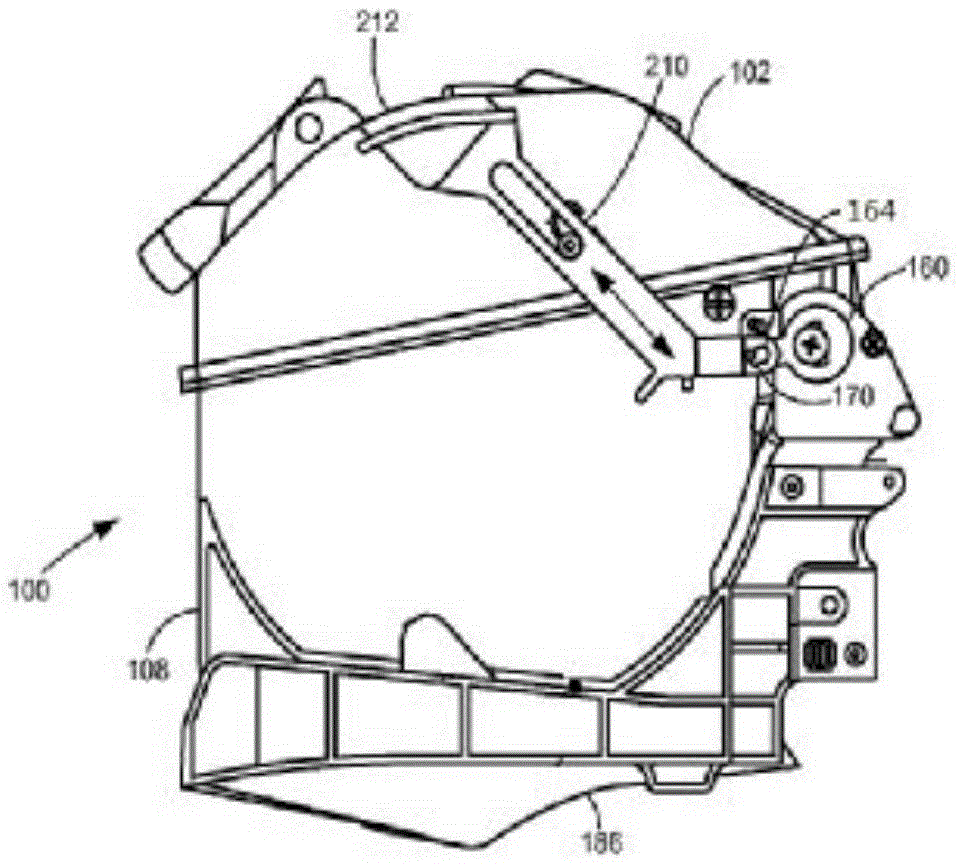

[0070] Such as Figure 4 and Figure 5 As shown, the toner cartridge of the present invention includes: a casing 1 , a first end cover 2 and a second end cover 3 respectively arranged on two sides of the casing 1 . The housing 1 includes: a powder bin body 11 and a powder bin cover 12, the powder bin body 11 and the powder bin cover 12 are connected together by welding to form a housing body, and the inside of the housing body constitutes a toner storage bin. The first end cover 2 and the second end cover 3 are detachably installed on the first side wall 14 and the second side wall 15 of the housing body respectively, and the position above the front end of the powder bin body 11 is provided with Toner delivery slot 112.

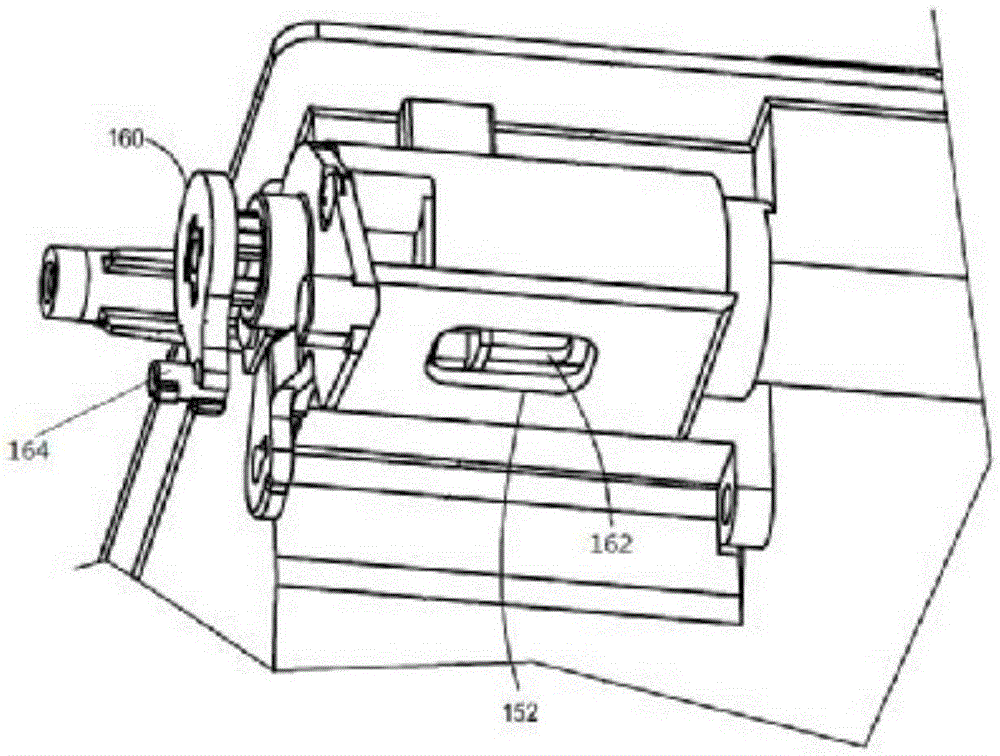

[0071] A gear train 17 is arranged between the second side wall 15 of the housing main body and the second end cover 3, the gear train 17 includes a driving force input gear and a plurality of power transmission gears, and the driving force input gear part...

Embodiment 2

[0084] Such as Figure 4 and Figure 5 As shown, the toner cartridge of the present invention includes: a casing 1 , a first end cover 2 and a second end cover 3 respectively arranged on two sides of the casing 1 . The casing 1 includes: a powder bin body 11 and a powder bin cover 12, and the powder bin body 11 and the powder bin cover 12 are connected together by welding to form an inner space for storing carbon powder. The inside of the powder bin body 11 is provided with a carbon powder stirring device 13, the stirring device 13 is rotatably installed between the first side wall 14 and the second side wall 15 of the housing 1, the stirring device 13 includes a stirring frame 131 and is mounted on The stirring blade (not shown in the figure) on the stirring frame 131, the stirring device 13 can rotate in the cavity of the powder bin to stir the carbon powder. The front end of the powder bin body 11 extends along the axial direction of the powder bin body 11 and is provided...

Embodiment 3

[0094] This embodiment proposes another structure of the toner cartridge, such as Figure 12-15 As shown, the toner conveying part 115 is provided with a hollow outer cylinder 1152, and one end of the powder feeding screw 16 extends into the outer cylinder 1152; the peripheral wall of the outer cylinder 1152 facing the bottom of the toner cartridge is provided with an external powder outlet The opening 11520 ; the outer wall of the bottom of the outer cylinder 1152 is provided with a powder outlet switch 24 , the powder outlet switch 24 is a slide member and can slide outside the toner conveying part 115 .

[0095] Specifically, on the outer wall of the bottom of the outer cylinder 1152, the part covering the external powder outlet opening 11520 is provided with a receiving part 1153, and two slide grooves 1154 are provided at the bottom of the receiving part 1153, and at the bottom of the receiving part 1153 The middle position is also provided with a concave portion 1155 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com