Anti-collision protector for pile body

An anti-impact, protective body technology, applied in climate change adaptation, roads, shipping equipment, etc., can solve the problems of inability to achieve good protection of the column, complex structure of the column protector, increased cost of column protection, etc., and achieve a simple structure. , The effect of easy promotion and application, short operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

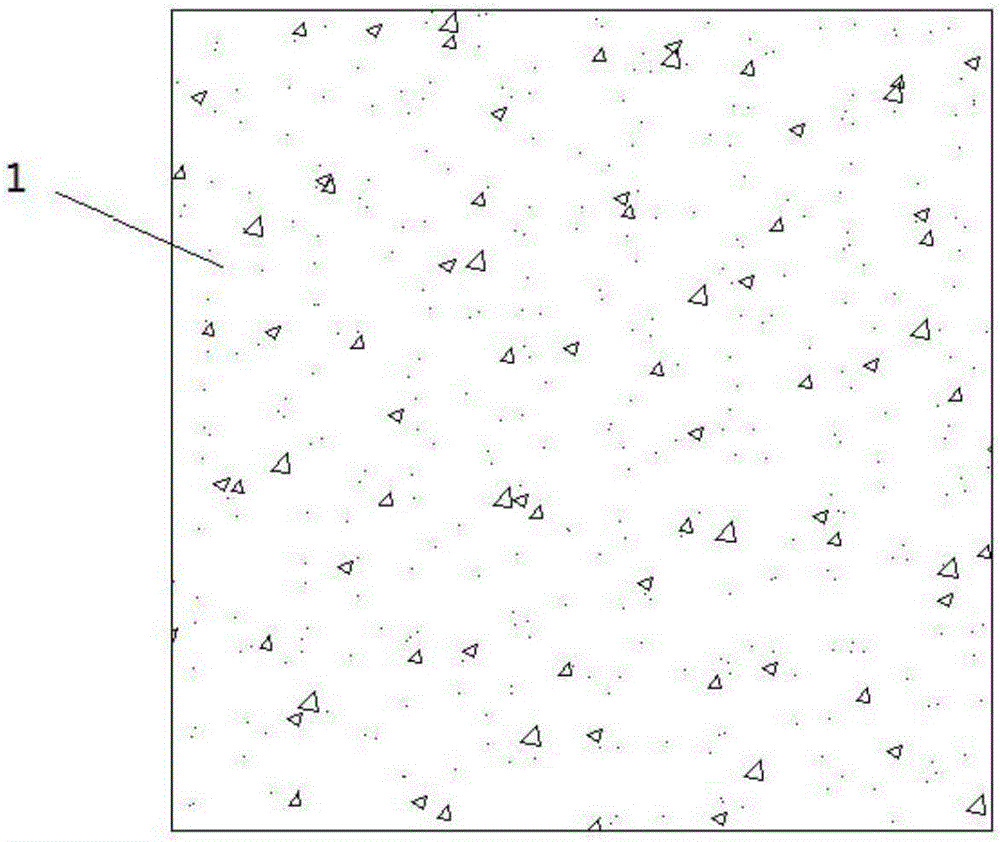

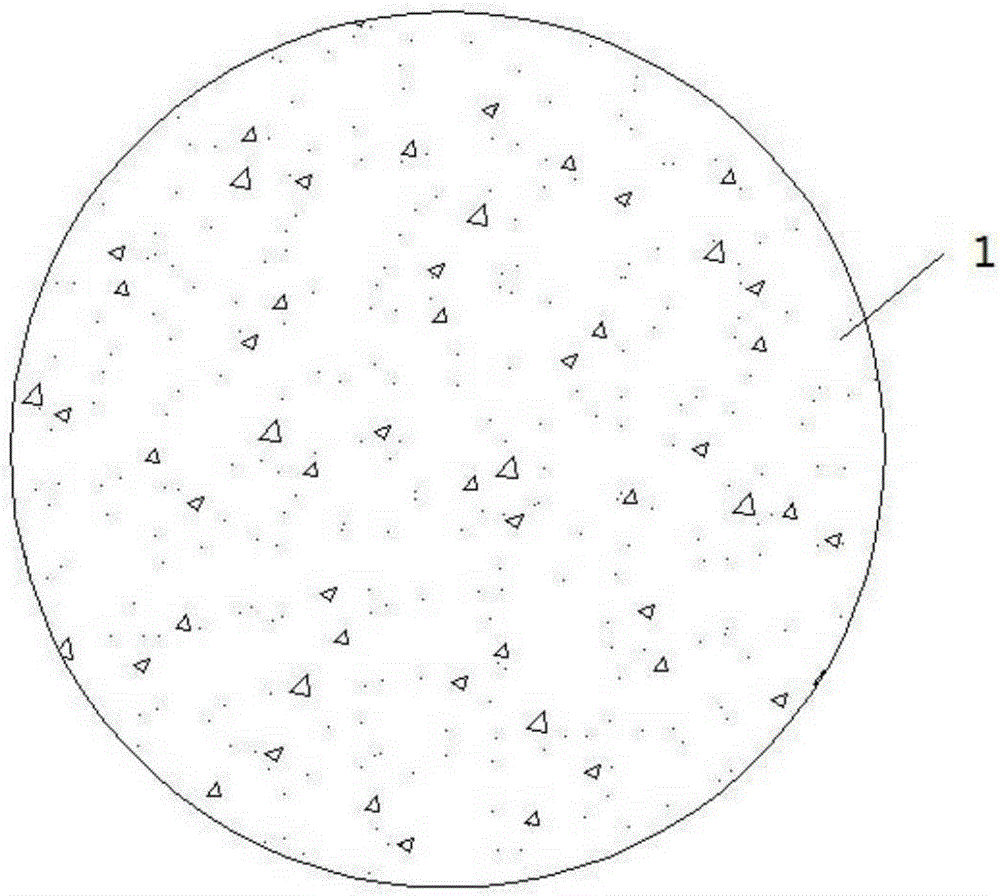

[0033] Referring to Fig. 1 and Fig. 2, a column anti-collision protection body includes a protective body 2 ringed outside the column body 1 and a fiber cloth 4 ringed outside the protective body 2, the protective body 2 is in rubber concrete Steel mesh rubber concrete protective body or fiber mesh rubber concrete protective body made of fine steel wire mesh or fiber mesh as reinforced skeleton; the rubber replacement rate of the above rubber concrete is 10%-20%, which is a short Made by mixing fibers and rubber particles into concrete.

[0034] In this embodiment, there are 1-2 layers of fiber mesh and reinforcement mesh, and the mesh size of each layer of fiber mesh and reinforcement mesh is 5mm-15mm; and the fiber mesh is made of carbon fiber, basalt fiber, aramid fiber or glass fiber. The short fibers are steel fibers, glass fibers or natural plant fibers, and the volume content of the short fibers is 0-3%. Rubber pellets are made from discarded rubber tires from cars.

...

Embodiment 2

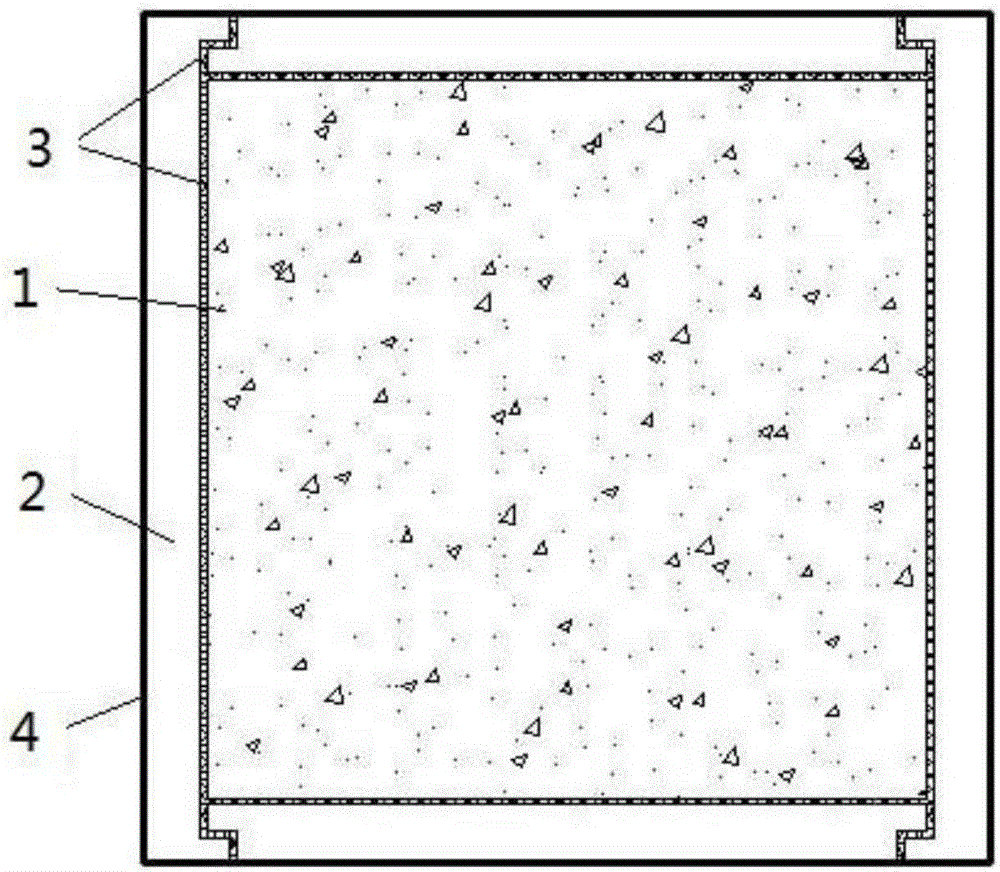

[0046] Embodiment 2, referring to Fig. 3 and Fig. 4, differs from Embodiment 1 in that: the protective body is provided with a reserved through hole; the column body 1 is provided with stainless steel bolts 5 corresponding to the reserved through holes, and the stainless steel bolts 5 is fixed by the nut 6 after passing through the reserved through hole and the gasket 7, and the protective body is fixed on the cylinder 1. Structural glue 3 is first injected into the gap between the stainless steel bolt 5 and the column body 1, and then the grouting material 8 is poured in to ensure the stability of the structure. The specific steps are: leveling the surface of the cylinder 1, and drilling according to the reserved through hole of the protective body, after implanting the stainless steel bolt 5, first inject the structural glue 3 into the gap between the stainless steel bolt 5 and the cylinder 1 and grouting material 8; after the stainless steel bolt 5 passes through the protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com