CNT@Fe3O4@C modified polymer hybrid proton exchange membrane and preparation method thereof

A proton exchange membrane and polymer technology, applied in the field of polymer hybrid proton exchange membrane and its preparation, can solve the problems of hybrid membrane proton conductivity enhancement, limited, low effectiveness, etc., to achieve a good industrial production basis, broad Application prospect, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

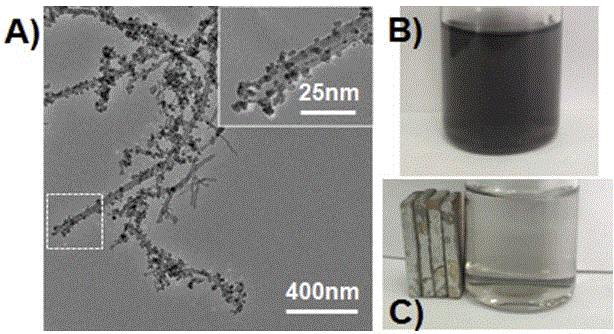

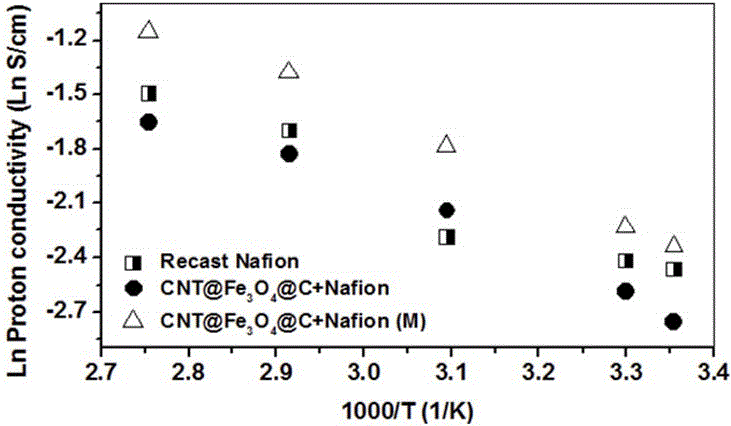

[0023] Prepare 10 mL of 10 mg / mL CNT-COOH / acetone dispersion; then, add 100 mg of ferrocene, and disperse evenly; then, add 1 mL of 30 wt% hydrogen peroxide solution, and mix evenly; place the above system at 210°C After 24 h, let it cool naturally, and finally wash with ethanol-centrifugation to collect the product CNT@Fe 3 o 4 @C. figure 1 (A) for CNT@Fe 3 o 4 TEM image of @C, it can be seen that Fe 3 o 4 @C is randomly and uniformly adsorbed on the CNTs, thereby forming composite nanoparticles with an overall 1D shape. CNT@Fe 3 o 4 @C has good magnetic responsiveness ( figure 1 (B / C)).

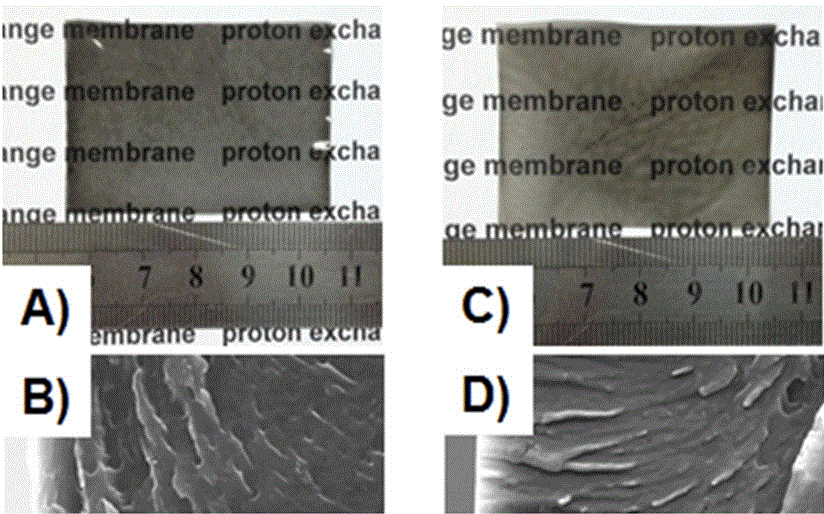

[0024] Take 5 mL of commercially available Nafion solution, remove about half of the solvent by rotary evaporation, add 2.5 mL N,N-dimethylformamide, and continue rotary evaporation for 10 min; add 0.5 wt of Nafion polymer equivalent to the above Nafion solution %CNT@Fe 3 o 4 @C, Ultrasound for 1 h to disperse evenly; carefully pour the dispersion into a mold and quickly place i...

Embodiment 2

[0028] Prepare 10 mL of 10 mg / mL CNT-COOH / acetone dispersion; then, add 75 mg of ferrocene, and disperse evenly; then, add 1 mL of 30 wt% hydrogen peroxide solution, and mix evenly; place the above system at 210°C for 24 After h, let it cool down naturally, and finally wash with ethanol-centrifugation to collect the product CNT@Fe 3 o 4 @C.

[0029] Take 5 mL of commercially available Nafion solution, remove about half of the solvent by rotary evaporation, add 2.5 mL N,N-dimethylformamide, and continue rotary evaporation for 10 min; add 0.5 wt of Nafion polymer equivalent to the above Nafion solution %CNT@Fe 3 o 4 @C, Ultrasound for 1 h to disperse evenly; carefully pour the dispersion into a mold and quickly place it in an oven at 70 °C, apply a uniform 0.3 T magnetic field in the film thickness direction, and start from 70 °C for 2 h After that, the temperature was slowly raised to 120°C to remove the solvent; vacuum was applied, and the temperature of the vacuum oven wa...

Embodiment 3

[0031] Prepare 10 mL of 10 mg / mL CNT-COOH / acetone dispersion; then, add 50 mg of ferrocene, and disperse evenly; then, add 1 mL of 30 wt% hydrogen peroxide solution, and mix evenly; place the above system at 210°C for 24 After h, let it cool down naturally, and finally wash with ethanol-centrifugation to collect the product CNT@Fe 3 o 4 @C.

[0032] Take 5 mL of commercially available Nafion solution, remove about half of the solvent by rotary evaporation, add 2.5 mL N,N-dimethylformamide, and continue rotary evaporation for 10 min; add 0.5 wt of Nafion polymer equivalent to the above Nafion solution %CNT@Fe 3 o 4 @C, Ultrasound for 1 h to disperse evenly; carefully pour the dispersion into a mold and quickly place it in an oven at 70 °C, apply a uniform 0.3 T magnetic field in the film thickness direction, and start from 70 °C for 2 h After that, the temperature was slowly raised to 120°C to remove the solvent; vacuum was applied, and the temperature of the vacuum oven wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com